Iron oxide powder is widely used in coatings, building materials, ceramics, magnetic materials and other fields, and efficient and stable iron oxide powder production line equipment is the key to ensure product quality and production capacity. As a professional full-set processing machinery manufacturer, we provide integrated solutions from raw material processing to finished product packaging to help customers achieve automation, high output and low energy consumption production goals.

This article will introduce in detail the core equipment, process flow, technical advantages of the iron oxide powder production line, and how to choose suitable iron oxide powder processing machinery.

1. Core equipment of iron oxide powder production line

A complete set of iron oxide powder production line usually includes the following key equipment:

① Raw material pretreatment system

Crusher: crush the raw materials (such as iron scale, ferrous sulfate, etc.) to a suitable particle size.

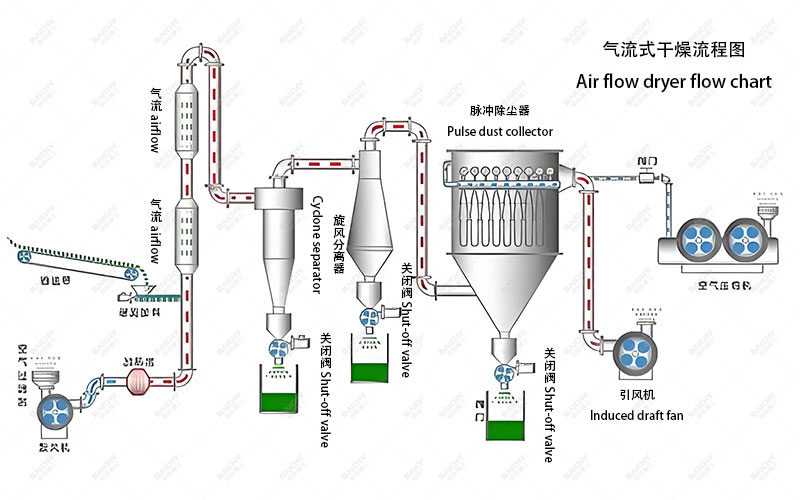

Dryer: remove moisture from the raw materials to improve the efficiency of subsequent calcination.

② Calcination equipment

Rotary kiln/tunnel kiln: high temperature calcination (800-1200℃) to convert raw materials into red iron oxide (Fe₂O₃) or black iron oxide (Fe₃O₄).

Energy-saving design: waste heat recovery system can reduce energy consumption by more than 30%.

③ Grinding and classification system

Raymond mill/ball mill: grind the calcined block material into fine powder (80-400 mesh).

Airflow classifier: ensure uniform powder particle size to meet the needs of different industries.

④ Packaging and dust removal system

Automatic packaging machine: 25kg/50kg bag or ton bag packaging, support customized specifications.

Pulse dust collector: meet environmental protection standards and reduce dust pollution during the production process.

2. Iron oxide powder production process flow

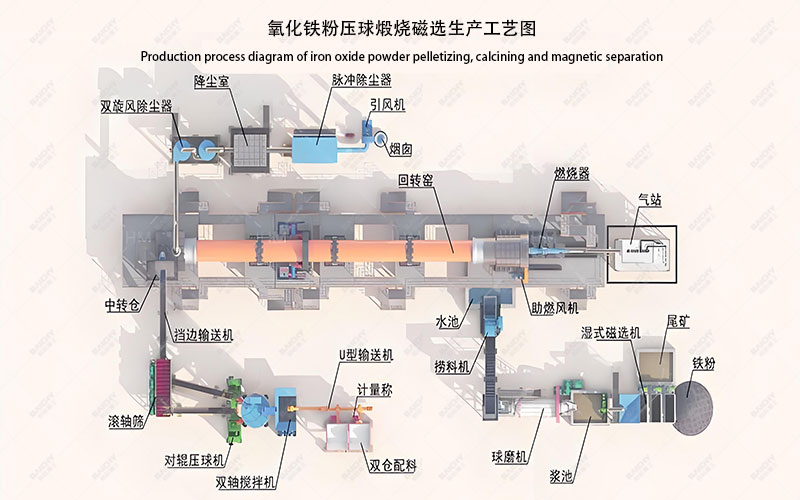

The typical iron oxide powder production line process is as follows:

Raw material preparation → 2. Drying and dehydration → 3. High temperature calcination → 4. Grinding and grading → 5. Packaging and warehousing

Key control points:

Calcination temperature and time (affects color and purity).

Grinding fineness (determines product application areas, such as coatings require ultrafine powder).

3. Production line technical advantages

As a professional iron oxide powder equipment manufacturer, our solution has the following advantages:

✔ High automation: PLC control system, reducing manual intervention.

✔ Energy saving and environmental protection: waste heat utilization + dust removal design, in line with international environmental standards.

✔ Flexible customization: Supports production lines of different scales with an annual output of 1,000-50,000 tons.

✔ Global service: Made in India, exported to the Middle East, Southeast Asia, Africa and other markets.

4. How to choose iron oxide powder production equipment?

Customers need to consider the following when choosing equipment:

• Capacity requirements: Small laboratory line or large-scale industrial line?

• Product type: The processes of red, black and yellow iron oxide powders are slightly different.

• Budget and energy efficiency: The higher the degree of automation, the greater the initial investment, but the long-term operating cost is lower.

Case sharing:

We once designed a 10,000-ton red iron oxide powder production line for a Vietnamese customer. By optimizing the calcination process, the product purity reached 98.5% and the energy consumption was reduced by 20%.

The performance of the iron oxide powder production line directly affects the product quality and market competitiveness. As an experienced manufacturer of iron oxide powder processing machinery, we provide full-process support from equipment selection, installation and commissioning to technical training.

Consult now to get a customized iron oxide powder production line solution!