In industries such as mining, aggregate production, and construction waste processing, crushers are core production equipment. Different types of crushers (jaw crushers, impact crushers, and cone crushers) differ significantly in their principles, applicable materials, and output results. Improper selection can lead to a series of problems, including low production efficiency, soaring operating costs, and substandard finished product particle shape. As a mining crushing equipment manufacturer with 20 years of experience, we understand that matching the most suitable equipment for our customers is the foundation of project success. This article will provide an in-depth analysis of these three mainstream crushers to help you make informed decisions.

Equipment Overview and Core Differences

jaw crusher

Jaw Crusher

The jaw crusher is the absolute workhorse of the primary crushing stage. It crushes materials using the principle of compression between a moving jaw and a fixed jaw, boasting a robust structure and excelling at processing large, high-hardness raw materials (such as granite and basalt).

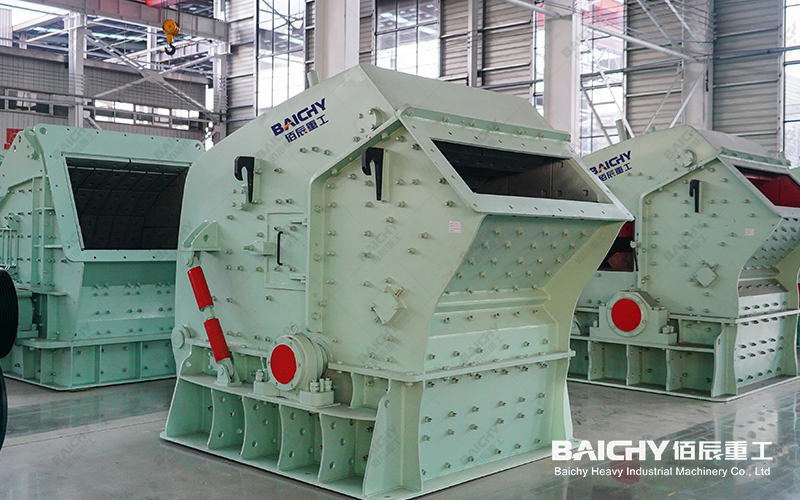

PF Impact Crusher

Impact Crusher

The impact crusher is a commonly used device for medium and fine crushing, utilizing impact energy to crush materials. The hammer strikes the material at high speed, causing it to impact the impact plate, achieving repeated crushing. It is particularly suitable for processing materials of medium hardness and below, where a high-quality particle shape is required (such as limestone and concrete).

Cone Crusher

Cone Crusher

The cone crusher is also used for medium and fine crushing, but employs the laminated crushing principle. Through the gyratory motion of the moving cone, the material is continuously compressed and ground. Its core advantages lie in its high efficiency, stability, and low wear when processing high-hardness materials, making it a reliable choice for the fine crushing stage in large-scale stone production lines.

Comparison of Core Advantages of the Three Crushers

| Equipment Type | Core Advantages | Best Applicable Scenarios |

| Jaw Crusher | Large feed opening, high crushing ratio, simple and durable structure, easy maintenance, ideal for primary crushing. | Primary crushing in mines, initial crushing of large materials. |

| Impact Crusher | Produces well-shaped, cubic-shaped finished products with low needle and flake content; easy to adjust discharge particle size, offering high flexibility; relatively low equipment investment. | Suitable for the production of construction aggregates with strict requirements on stone shape; crushing materials of medium and lower hardness. |

| Cone Crusher | High production efficiency, stable operation, long wear part life, and low unit energy consumption, making it the preferred choice for high-yield, continuous production. | Secondary or tertiary crushing in large-scale crushing lines for high-hardness materials (such as granite and river pebbles). |

Selection Guide: How to Make Decisions Based on Your Needs?

1. Consider material hardness and size: For high-hardness, large-sized materials, a jaw crusher is the first choice for primary crushing; for medium-to-low hardness materials where particle shape is important, an impact crusher is suitable; for high-hardness materials requiring high yield and stable production, a cone crusher is recommended.

2. Consider finished product requirements: For strict requirements on cubic particle shape (such as high-grade highway surface materials), the impact crusher is superior; if the main requirement is mixed aggregates of various specifications, the cone crusher is more economical and efficient.

3. Consider production scale and budget: For small and medium-sized production lines, the impact crusher offers a faster return on investment; for large-scale, intensive production lines, the long-term operating cost advantages of the cone crusher are more significant.

4. Consider production line configuration: The typical jaw crusher + impact crusher/cone crusher two-stage configuration is the industry mainstream; the specific combination requires careful calculation.

Practical Application Case Studies

Case Study 1: A Large Granite Aggregate Project in East China

- Challenge: High material hardness (Mohs hardness level 7), requiring a production capacity of 1000 tons per hour, with the finished product used for high-grade commercial concrete.

- Solution: A combination of a large-capacity heavy-duty jaw crusher (coarse crushing) and a multi-cylinder hydraulic cone crusher (medium and fine crushing) was used.

- Result: The production line operated smoothly, the wear parts of the cone crusher lasted for more than 3 months, and the finished product particle size was excellent, fully meeting the customer's needs.

Case Study 2: A Construction Waste Recycling Project in North China

- Challenge: Processing complex construction waste, requiring the removal of impurities such as rebar, and producing high-quality recycled aggregate.

- Solution: A configuration of jaw crusher (for primary crushing and uniform feeding) + heavy-duty impact crusher (for main crushing and shaping) was adopted.

- Results: The impact crusher effectively ensured the particle shape of the recycled aggregate, resulting in strong market competitiveness and significant economic benefits for the project.

Our Recommended Equipment

Based on 20 years of manufacturing and field service experience, we offer a full range of crushing solutions:

- C-series Jaw Crushers: Utilizing high-strength materials and optimized cavity design, crushing efficiency is increased by 20%.

- I-series Impact Crushers: Heavy-duty rotor design, combining high crushing ratio with excellent shaping effect.

- H-series Multi-cylinder Hydraulic Cone Crushers: Intelligent hydraulic system allows for remote adjustment of the discharge opening and cavity cleaning, making maintenance safer and more convenient.

We support customized solution design and full lifecycle services, from site survey to installation and commissioning, providing you with comprehensive support.

Frequently Asked Questions (FAQ)

Q1: Both jaw crushers and cone crushers can crush high-hardness rocks, so how do I choose?

A1: The key is the crushing stage and your needs. Jaw crushers are for primary crushing, used to process very large raw materials directly from the mine. Cone crushers are for secondary or tertiary crushing, used to further crush the semi-finished products from the jaw crusher to a smaller particle size. They usually work together.

Q2: Is there a significant difference in investment costs between impact crushers and cone crushers?

A2: Generally, for the same processing capacity, the initial purchase cost of an impact crusher is lower than that of a cone crusher. However, when processing high-hardness materials, cone crushers have better wear resistance of wear parts, and the long-term operating and maintenance costs may be lower. A comprehensive assessment of material properties, production duration, and other factors is needed to calculate the total cost of ownership.

Q3: Is it possible to complete the entire crushing process with only one type of crusher?

A3: For small-scale production, low-hardness materials, or specific requirements, single-stage crushing is possible. However, for most large-scale, professional stone production lines, a multi-stage crushing process (such as jaw crusher + impact crusher/cone crusher) or even more stages is the most economical and scientific way to ensure efficiency, output, and product quality.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.