Quartz stone crushing is an important link in the mining machinery industry. Since the main component of quartz stone is silica, it is a high-hard rock with hard, wear-resistant, and chemically stable properties. Therefore, it is necessary to choose appropriate crushing equipment and methods. Crucial.

The crushing methods of quartz stone mainly include extrusion crushing, lamination crushing, stone on stone, and stone on iron. Due to the high hardness of quartz stone, commonly used crushing equipment includes jaw crushers, cone crushers, impact crushers, etc.

The jaw crusher mainly uses the squeezing force generated when the two crushing working surfaces approach to crush the materials. Its crushing cavity is deep and suitable for coarse crushing processing. At the same time, the motion parameters are optimized so that the materials can start crushing in the upper part of the crushing cavity, and the lower stroke is large. , the crushing ratio is larger. The cone crusher adopts a laminated crushing method, and the bulk materials will be crushed along the cracks in the rock or the stress concentration points such as crystal defects.

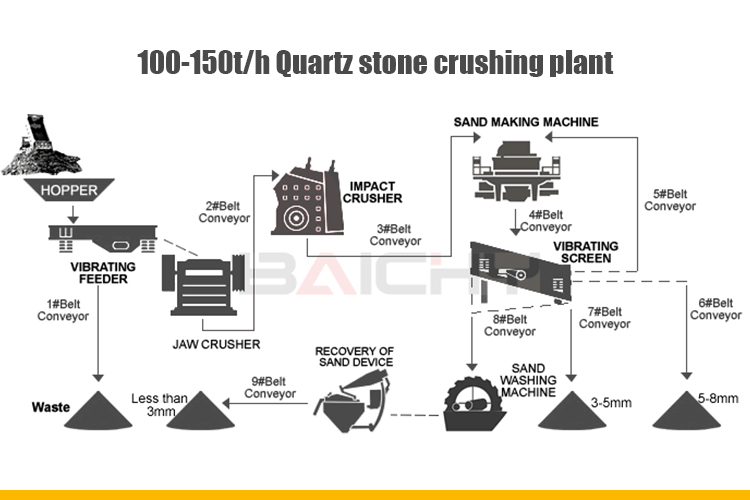

The process of quartz stone crushing generally includes the steps of coarse crushing, secondary crushing, and sand making. Coarse crushing is usually carried out by using a vibrating feeder in conjunction with a jaw crusher. Medium crushing is accomplished through a combination of a vibrating screen and a cone crusher. In the sand-making stage, a combination of impact crusher and sand washing machine is used to turn the crushed quartzite into Different sizes of sand.

In addition, the quartz sand roller crusher is also one of the main equipment for crushing quartz stone. Its structure is simple and reasonable, the crushing rate is as high as more than 90%, the discharge particle size is uniform, the output is high, and it is less affected by the moisture content of the material.

In general, quartz stone crushing requires the selection of appropriate crushing equipment and methods based on specific material characteristics and production needs to achieve efficient, stable, and economical crushing effects.