In the field of industrial grinding, the power transmission method directly determines the efficiency, reliability, and operating costs of equipment. Traditional large-scale grinding equipment generally employs a complex transmission structure of "motor + reducer + open gear," whose inherent energy loss, frequent maintenance, and oil leakage risks have become bottlenecks restricting production efficiency and profit margins.

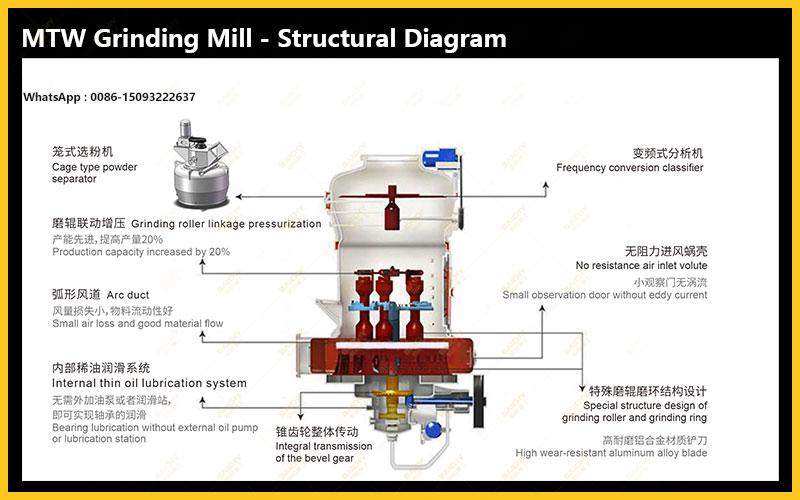

The core breakthrough of the MTW series European-style mill lies in its revolutionary bevel gear transmission technology, achieving ultimate energy efficiency from the power source and leading a quiet, powerful, and sustained efficiency revolution.

I. Bevel Gear Transmission VS Traditional Transmission

To understand the advantages of the MTW mill, it is essential to first understand the drawbacks of traditional transmission systems.

• Traditional transmission path (complex and inefficient): Motor → Reducer → Drive shaft → Large open gear → Grinding roller.

• MTW bevel gear transmission path (direct and efficient): Motor → Vertically mounted bevel gear assembly → Grinding roller.

This fundamental difference in structure leads to a dramatic difference in performance. Below, we will analyze in detail the five core advantages of bevel gear transmission technology.

II. Five Core Advantages of Bevel Gear Transmission Technology

Advantage 1: Significantly Improved Transmission Efficiency and Drastically Reduced Energy Consumption

• Technical Principle: The vertical bevel gear transmission system boasts an extremely compact structure and a significantly shortened transmission chain, virtually eliminating mechanical energy losses in multi-stage transmissions.

• Value Proposition: Transmission efficiency is increased from less than 90% in traditional methods to an astonishing 98% or more. This means more electrical energy is directly used for material grinding rather than wasted energy, resulting in a substantial reduction in power consumption for the same output, directly saving customers considerable operating costs.

Advantage 2: Lifetime Maintenance-Free, Achieving Ultimate Reliability

• Technical Principle: The entire transmission system is sealed within the gearbox, employing an advanced thin oil lubrication solution. Compared to traditional grease-lubricated open gears, lubrication is more thorough and even, with virtually no risk of oxidation or leakage.

• Value Proposition: Achieves lifetime maintenance-free operation. Customers no longer need to worry about gear wear, regular lubrication, or troubleshooting oil leaks, greatly reducing maintenance workload and unnecessary downtime, ensuring continuous and stable operation of the production line. This is particularly suitable for large-scale grinding equipment projects with extremely high equipment reliability requirements.

Advantage 3: Extremely Smooth Operation, Low Vibration and Noise

• Technical Principle: The precision meshing of the bevel gears and the integral housing structure provide superior rigidity, ensuring smooth and stable power transmission and eliminating the impact and vibration caused by the backlash in traditional open gear systems.

• Value Proposition: Significantly reduced vibration and noise during equipment operation. This not only creates a more user-friendly working environment but also greatly reduces fatigue damage to the main unit and foundation structure caused by vibration, extending the overall service life of the machine and improving the fineness and uniformity of the finished powder.

Advantage 4: Compact Structure, High Space Utilization

• Technical Principle: Eliminating the bulky reducer and large open gear pair, the entire transmission assembly is cleverly designed with a small footprint.

• Value Proposition: Provides greater flexibility in the layout planning of the entire grinding system, helping to create a more compact and rational production line, especially suitable for installation or upgrades in space-constrained plant areas.

Advantage Five: Powerful Power, Providing a Solid Foundation for High Yield

• Technical Principle: The bevel gear drive boasts excellent torque capacity, delivering direct and powerful power output without any slippage.

• Value Proposition: Provides a continuous and stable power source for the grinding unit, ensuring the grinding rollers apply sufficient grinding pressure to the material. This is one of the fundamental reasons why the MTW European-style mill can increase output by up to 30% compared to traditional equipment at the same power, fully unleashing its production potential.

III. Technical Parameters of the MTW Series European-style Mill

| Model | Roller Size (mm) | Grind Ring Size DxH(mm) | Main Roller Speed (r/min) | Max Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Power (Kw) | Overall Dimension (mm) |

| MTW110 | 360×210 | 1100×210 | 120 | 30 | 0.038-1.6 | 4-12 | 55 | 8910×6950×9010 |

| MTW138 | 460×260 | 1380×260 | 96 | 35 | 0.038-1.6 | 8-20 | 110 | 9860×8340×10227 |

| MTW175 | 520×300 | 1750×300 | 75 | 40 | 0.038-1.6 | 20-35 | 200 | 13500×11500×9500 |

| MTW215 | 640×340 | 2150×340 | 65 | 50 | 0.038-1.6 | 30-50 | 280 | 13922×9810×13226 |

IV. Choosing Us: More Than Just Advanced Technology, It's a Complete Solution

As a professional manufacturer of European-style mills, we understand that the success of an excellent large-scale grinding equipment relies on comprehensive support. We offer a complete productivity solution:

• Professional Selection and Design: Our engineering team will recommend the most suitable MTW mill model based on your material characteristics and production targets, providing optimized process flow diagrams and layout designs.

• Turnkey Project Services: We provide one-stop service from basic design, equipment supply, installation and commissioning to worker training, ensuring smooth project commissioning.

• Global After-Sales and Parts Support: We have established an efficient global supply chain and after-sales response system to ensure you receive timely technical support and original spare parts, guaranteeing the lifelong efficient operation of your equipment.

In an increasingly competitive market environment, upgrading core production equipment is the most direct way to reduce costs, increase efficiency, and enhance competitiveness. The bevel gear transmission technology used in the MTW series European-style mills is not simply a replacement of parts, but a complete revolution in traditional grinding power systems. It represents higher efficiency, lower maintenance costs, and more reliable long-term operating value.

Take action now and turn technological advantages into business advantages!

If you would like to learn more about how MTW mills can create value for your business, please contact us today. Click “Get a Free Quote” and our technical experts will provide you with customized technical solutions and a detailed equipment quotation.

FAQ

1. What materials are suitable for grinding with MTW mills?

This series of equipment is designed for large-scale processing of non-metallic minerals with medium to low hardness, such as limestone, calcite, barite, slag, and water slag, with excellent results.

2. What is the delivery time?

Depending on the model, we offer flexible delivery options. For standard models, we strive to minimize lead times. Please contact our sales team for details.

Further reading:

How To Choose A Suitable Industrial Grinding Mill?

Which Is Better Cement Vertical Roller Mill Or Ball Mill?

What Are the Differences between Dry and Wet Type Ball Mill?