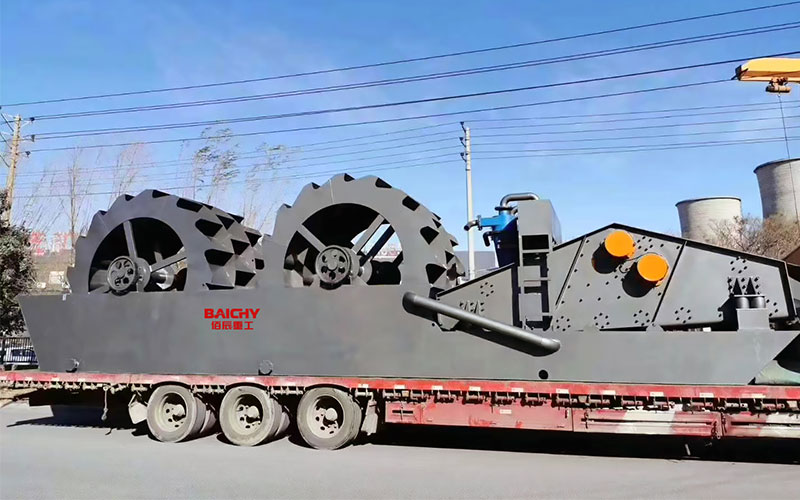

Concrete waste crushing

In fields such as building demolition, road reconstruction, and mining, the disposal of waste concrete and ore has always been a key challenge. As a manufacturer of mining crushing equipment with 20 years of experience, we have a deep global market presence, providing innovative solutions for various crushing scenarios. Today, we will highlight a high-efficiency piece of equipment—the mobile concrete crusher (mobile impact crusher)—with a crushing capacity of 60-100 tons/hour, designed to help customers improve efficiency, reduce costs, and achieve sustainable development.

Product Overview The mobile concrete crusher combines impact crushing technology with a mobile design, enabling it to be deployed directly to the work site to quickly crush concrete, construction waste, and medium-hardness ores. The core advantage of this equipment lies in its flexibility—it requires no fixed installation and can be moved at any time to adapt to perse site needs. With crushing capacities ranging from 60-100 tons/hour, users can adjust the output according to the actual project to ensure maximum resource utilization. As a manufacturer, we leverage 20 years of technological accumulation to continuously optimize the equipment, ensuring its reliable performance in harsh operating conditions worldwide.

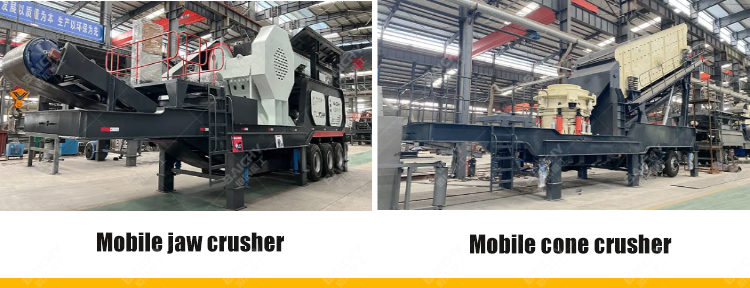

Mobile jaw & cone crusher

Product Advantages

• High-efficiency crushing and flexible mobility: The equipment integrates feeding, crushing, and conveying systems, enabling ready-to-use and significantly reducing material transportation and time costs. The impact crushing principle ensures that concrete is thoroughly pulverized, producing uniform aggregate.

• Energy saving and environmental protection: Adopting an advanced power system and low-noise design, it meets international environmental standards. The crushed aggregate can be directly recycled, reducing construction waste accumulation and supporting a circular economy.

• Intelligent control and durability: Equipped with a PLC automated control system, it is easy to operate and supports remote monitoring. Key components use high-strength materials, resistant to long-term impact wear, reducing maintenance frequency.

• Versatile adaptability: Not only suitable for concrete, but also for asphalt, rock, and other materials, offering multiple uses and improving return on investment.

Mobile concrete crushing plant

Application Scenarios

• Construction waste recycling: On-site processing of concrete fragments from urban demolition projects, producing recycled aggregate for new construction projects.

• Mines and quarries: Primary or secondary crushing of small to medium-sized ores, especially suitable for scenarios with dispersed mining areas and frequent relocation.

• Road and Bridge Reconstruction: Rapidly crushes old concrete pavement, accelerating construction progress.

• Emergency Engineering: Post-disaster debris clearing; mobile equipment can be quickly deployed to remote or traffic-restricted areas.

Project Cases

We have accumulated numerous successful cases globally. For example, a Southeast Asian construction company purchased a mobile impact crusher for an urban redevelopment project. This equipment processes 80 tons of waste concrete per hour, converting the crushed material into roadbed material, reducing project costs by 30% and shortening the construction period by 40%. Customer feedback: This crusher has changed our working methods. Now we can process materials directly on-site, without relying on external crushing plants; the efficiency is amazing.

FAQ

1. Does the equipment require special foundation installation?

No. The mobile design, equipped with tires or tracks, can operate directly on level ground, reducing preliminary preparation work.

2. How are the aggregate dimensions adjusted after crushing?

The output aggregate size can be controlled by adjusting the impact plate gap or rotation speed, typically adjustable within the range of 0-40mm.

3. Is the equipment suitable for rainy or rugged terrain?

Yes. We offer rust and dust resistant configurations, and the tracked models are better suited for muddy or mountainous environments.

4. Does the manufacturer provide technical support?

We provide global after-sales service, including installation guidance, operation training, and spare parts supply, ensuring continuous and stable equipment operation.

Mobile concrete crushers represent the flexibility and efficiency of modern crushing technology. As an industry leader for 20 years, we are committed to helping customers meet resource processing challenges through innovative equipment. If you are looking for a reliable, high-yield crushing solution, please contact us for customized consultation—let's work together to transform waste into new value!

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.