In the fields of mining and large-scale aggregate production, the efficiency of primary crushing directly determines the capacity and cost of the entire production line. As the "backbone" of this process, gyratory crushers, with their unique design and superior performance, have become the preferred choice for many high-standard projects. This article will delve into this critical primary crushing equipment and explore how it can create greater value for your project.

What is a Gyratory Crusher? A Core Principle Analysis

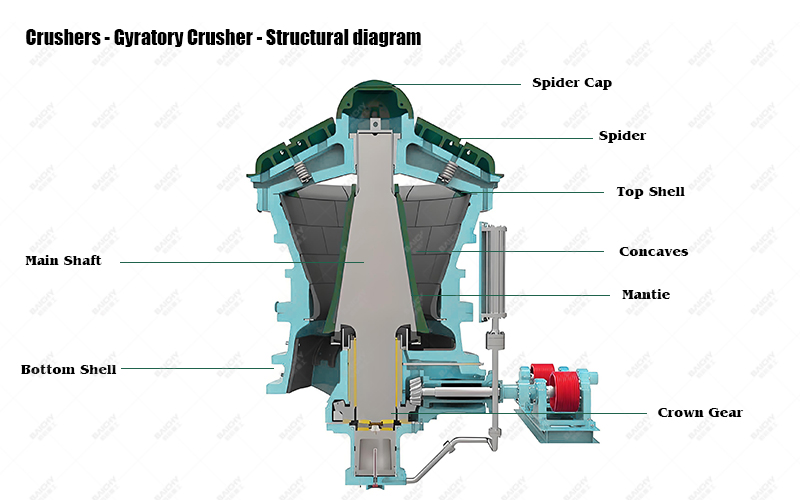

A gyratory crusher is a large-scale continuous operation equipment used for primary crushing. Its core principle is to drive a movable cone to perform a gyratory motion through an eccentric sleeve installed on the upper part of the main shaft. This causes the gap between the movable cone and the fixed liner to change periodically, thereby compressing, bending, and splitting the material falling into the cavity, achieving continuous crushing.

Unlike the reciprocating crushing method of jaw crushers, gyratory crushers operate continuously, giving them a significant advantage in processing capacity per unit time, making them particularly suitable for processing high-hardness, large-sized ores or rocks.

Gyratory Crusher PDF, Download ↓↓↓

| Key Words |

Limestone Crushing & Screening Plant |

| Product Model |

Gyratory Crusher |

| Feed Size |

≤1300mm |

| Motor Power |

400-1250kw |

| Capacity |

2015-8895t/h |

| Core Advantages |

Annular cavity laminated crushing |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Core Advantages of Gyratory Crushers: Why Choose It?

1. Excellent High Capacity and Efficiency

Gyratory crushers have a larger feed opening and a continuous crushing stroke, capable of directly processing raw ore from the mine. The processing capacity per unit of power consumption is significantly higher than that of jaw crushers of the same specifications, laying a solid foundation for high-volume production lines.

2. Excellent Product Granularity and Stability

The crushing chamber shape is optimized to produce a more uniform product with a higher cubic content, which is beneficial for the next stage of crushing. The stable output particle size reduces fluctuations and load on subsequent processes.

3. Low Operating and Maintenance Costs

The structure is robust and durable, and core components such as the main shaft and liners are made of high-performance materials. Modern gyratory crushers are also equipped with automatic control systems, hydraulic discharge opening adjustment, and tramp iron protection devices, significantly reducing downtime and maintenance time, and lowering overall operating costs.

4. Strong Adaptability and Wide Application

It can easily handle high-hardness granite, iron ore, and copper ore, and is also suitable for medium-hardness limestone and basalt. Whether for fixed production lines or large semi-mobile crushing plants, it is a reliable primary crushing solution.

Successful Application Cases: Witnessing the Strength

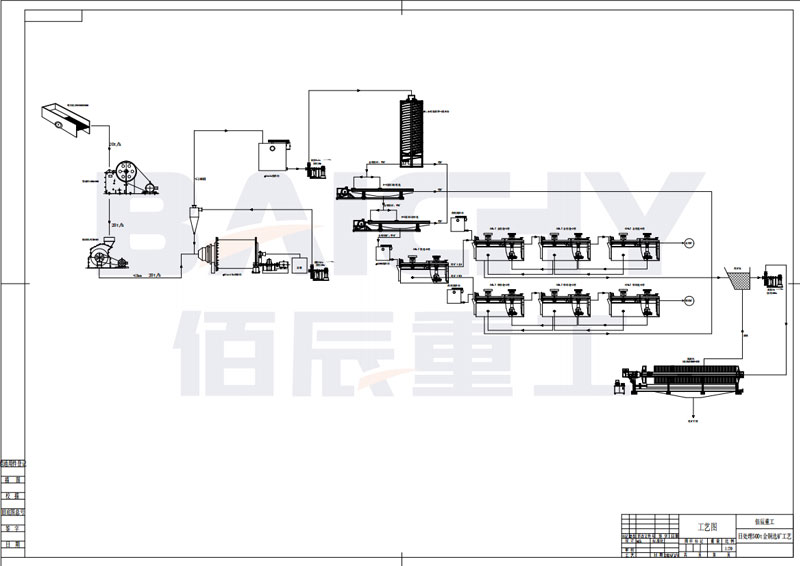

In a large iron ore project, the raw ore had a maximum particle size exceeding 1200mm, with high hardness and strong abrasiveness. The project owner ultimately selected a heavy-duty gyratory crusher provided by us as the primary crushing equipment.

Results: The equipment operated with a stable processing capacity of over 2000 tons per hour, successfully crushing the raw ore to below 250mm, providing ideal feed for subsequent secondary and tertiary crushing operations. Its excellent reliability and low liner wear rate provided the customer with a return on investment far exceeding expectations, ensuring the continuous and efficient operation of the entire production line.

Equipment Selection and Related Recommendations

When choosing a gyratory crusher, the following factors should be considered:

Material characteristics: hardness, abrasiveness, moisture content, maximum feed particle size.

Capacity requirements: target hourly or annual output.

Product requirements: target output particle size.

Installation form: fixed, semi-mobile, or as a core module of a mobile crushing plant.

We recommend that you communicate with our technical team at the initial stage of project planning. We will provide customized primary crushing solutions based on your specific working conditions and needs, and provide optimized feeders and downstream process equipment to ensure maximum system efficiency.

Frequently Asked Questions (FAQ)

Q1: How to choose between a gyratory crusher and a jaw crusher for primary crushing?

A: This mainly depends on capacity and investment budget. For large-scale crushing of high-hardness materials with a capacity of over 1000 tons per hour, gyratory crushers have significant advantages in efficiency, energy consumption, and product particle shape. For small and medium-sized projects with limited investment budgets or extremely high site flexibility requirements, a large jaw crusher may be a more economical choice. Our engineers can provide you with a detailed comparative analysis.

Q2: How long is the typical service life of gyratory crusher liners? Is replacement complicated?

A: Liner life varies depending on the abrasiveness of the material, usually ranging from 6 months to 2 years. Modern gyratory crusher designs fully consider ease of maintenance. The upper frame can be quickly removed via a hydraulic system at the top, and the liner replacement process has been greatly simplified, effectively reducing planned downtime.

Q3: Can it be integrated into mobile or semi-mobile crushing plants?

A: Absolutely. Although gyratory crushers are large, their modular design allows them to be integrated as the core crushing unit into large semi-mobile crushing plants. This solution combines the efficiency and stability of a fixed production line with a degree of site flexibility, making it particularly suitable for phased mining or open-pit mines that require shifting work areas.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!