40 t/h Electrically Heated Rotary Slag Dryer

First, based on the specifications provided by the client, we conducted a preliminary analysis of the project requirements to ensure that the subsequent solution is precisely matched:

I. Core Requirements Analysis and Key Technical Points Confirmation

1. Material Characteristics: Granular blast furnace slag, particle size <8mm. This is critical to the design; the fine particle size and good fluidity require careful consideration of dust control, anti-sticking measures, and the design of the lifting plates and airflow control to prevent excessive entrainment of fine particles by the airflow.

2. Core Process Indicators:

Throughput: 40 tons/hour (wet material input).

Dehumidification task: Reduce moisture content from 12% to 5%. This means evaporating approximately 2.95 tons of water per hour (40 tons (12%-5%) / (1-5%)). This is the basis for calculating heat consumption and dryer specifications.

Heat source: Electric heating hot air generator. This offers advantages in Latvia (EU) such as cleanliness, easy temperature control, and simple operation and maintenance, but operating costs are a significant consideration. The solution needs to focus on optimizing thermal efficiency.

3. Project Location: Latvia. This determines:

Transportation: Requires sea freight from a Chinese port to Riga or Ventspils port, including customs clearance.

Standards and Certifications: The equipment must comply with EU regulations such as CE certification and PED (Pressure Equipment Directive, if applicable).

Climate: The impact of ambient temperature on heat loss and installation and commissioning needs to be considered.

4. Scope of Supply Definition: It is clearly stated that "the feeding and discharge sections are not included in the scope of supply." Our quotation will strictly focus on the core components of the rotary dryer, hot air system, dust removal system, control system, etc., but the interfaces will be indicated in the process flow diagram for your integration.

II. To ensure the quality of the solution, we need to confirm the following information with you (please provide as much information as possible):

1. Initial state of the material: Is the wet slag loose or slightly agglomerated? This affects the feeding design and dust control.

2. Environmental requirements: Are there specific standards for the dust concentration in the exhaust gas (e.g., mg/Nm³)? This will determine the configuration level of the dust removal equipment (e.g., cyclone + bag filter).

3. Electrical and Control Systems: What are the power supply voltage and frequency at the project site (e.g., 400V/50Hz)? What are the basic requirements for the level of automation control (e.g., PLC, touch screen, remote monitoring)?

4. Installation Conditions: Is a concrete foundation already prepared? What are the expected installation space limitations (length, width, height)?

III. List of Documents We Will Provide

As you requested, we will provide the following complete documents, which form the core of your solution:

1. Preliminary Budget Quotation Estimate (itemized):

◦ Equipment costs (rotary dryer drum, drive unit, electric hot air generator, cyclone dust collector, bag filter, fan, PLC control system, etc.)

◦ Packaging and transportation costs to the designated port in Latvia

◦ Service fees for on-site installation guidance and commissioning by our engineers (excluding local labor and lifting equipment)

2. Reference Cases: A list of our past successful rotary dryer projects handling slag/similar materials with a capacity of 20-100 tons/hour (including key information such as customer country, material, capacity, evaporation rate, etc.).

3. Technical Solution Documents:

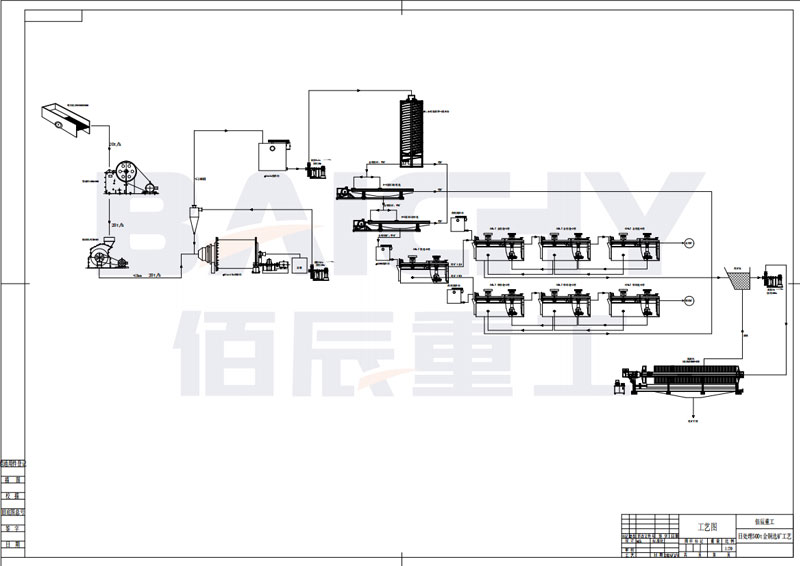

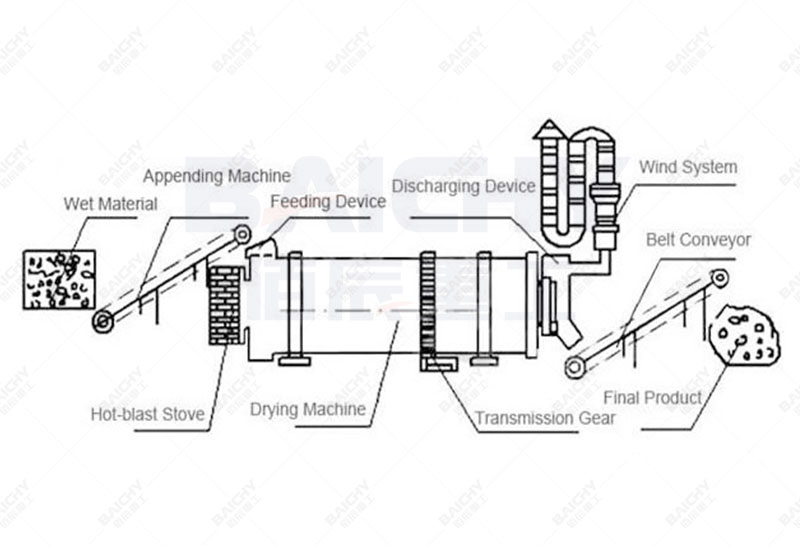

◦ Process Flow Diagram (PFD): Showing the complete process from wet material inlet to dry material outlet, and from hot air to exhaust gas treatment.

◦ Process Calculation Explanation: Detailed heat balance and mass balance calculations to determine key parameters such as total power consumption, airflow rate, and exhaust temperature.

◦ Key Design Assumptions: Including residence time setting, expected thermal efficiency, and moisture evaporation and temperature distribution curves within the drum.

Drying machine process flow and structural diagram

4. Main Drawings:

◦ General Assembly Drawing: Showing the overall dimensions, weight, main component layout, and interface locations of the equipment.

◦ Lifting Plate Arrangement Drawing: Showing the arrangement and design of the lifting plates inside the drum to ensure optimal material scattering and heat exchange.

◦ Drum and Lining Detail Drawing: Illustrating the drum thickness, material (e.g., Q345R), and the design of the internal wear-resistant lining (e.g., heat-resistant steel scales or ceramic plates).

◦ Hot Air Inlet Detail Drawing: Including interface flange dimensions, recommended pipe sizes, airflow velocity suggestions, and expansion joint settings. Next steps:

Our technical team has started designing a solution based on the available information. Please confirm the information in point two above at your earliest convenience, as this will allow us to further optimize the design and provide the most accurate quote.

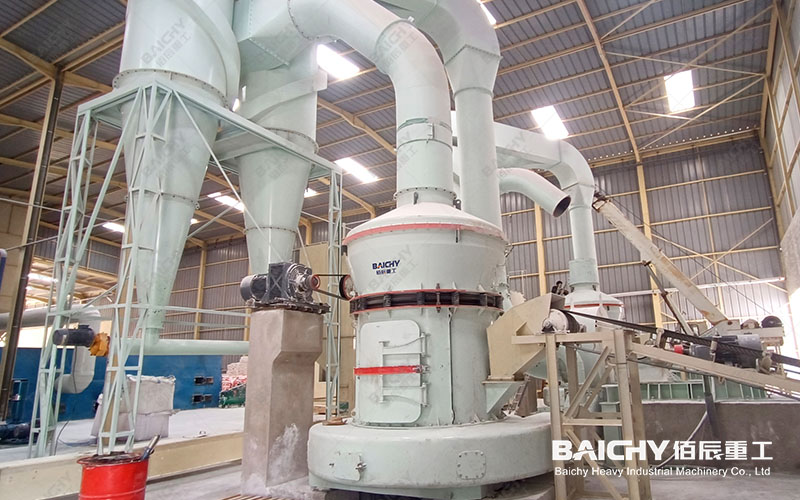

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!