Gyratory Crusher

As a manufacturer deeply rooted in the field of mobile crushing equipment for mining, we understand that choosing an excellent gyratory crusher manufacturer is far more than simply purchasing a piece of equipment. It concerns the operational efficiency, cost control, and return on investment of the entire mining project for the next ten years or even longer. This article will analyze the core factors to consider when choosing a partner and explain why the manufacturer's overall strength is crucial.

Gyratory Crusher PDF, Download ↓↓↓

I. Topic Analysis: Why is the Manufacturer's Choice So Critical?

As a capital-intensive and technology-intensive core mining equipment, the performance, reliability, and lifespan of a gyratory crusher depend heavily on the manufacturer's comprehensive capabilities. An excellent gyratory crusher manufacturer should possess profound design and engineering expertise, superior manufacturing processes, comprehensive testing capabilities, and a service system covering the entire equipment lifecycle. An improper choice can lead to frequent equipment failures, substandard production capacity, and inadequate spare parts supply, resulting in significant production losses. Therefore, evaluating the manufacturer is a prerequisite for choosing the equipment.

II. Overview: Core Characteristics of Top Manufacturers

Leading gyratory crusher manufacturers in today's market typically possess the following common characteristics, which form the foundation of their products' superior performance:

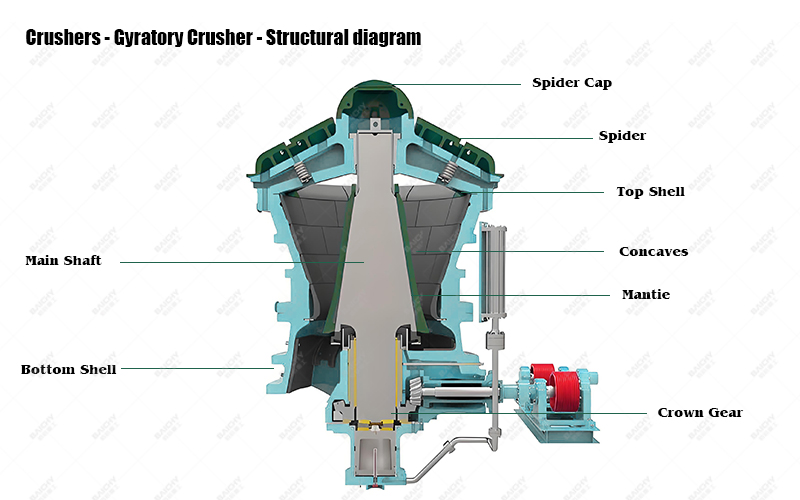

Design and R&D Capabilities

They have a strong R&D team, utilizing advanced finite element analysis (FEA) and dynamic simulation software for crushing chamber shape optimization and structural stress analysis, ensuring the structural integrity and efficient crushing of the equipment under extreme working conditions.

Manufacturing and Quality Control

They possess heavy-duty machining capabilities, advanced heat treatment processes, and a rigorous quality inspection system (such as ultrasonic testing and hardness testing). From large castings and forgings to precision transmission components, a fully controllable quality chain guarantees the durability of the equipment.

Global Service and Support Network

They can provide comprehensive services ranging from installation guidance, commissioning, and operation training to preventive maintenance, rapid spare parts response, and on-site technical support. A strong localized service team is the "guardian" of the equipment's long-term stable operation.

| Key Words |

Limestone Crushing & Screening Plant |

| Product Model |

Gyratory Crusher |

| Feed Size |

≤1300mm |

| Motor Power |

400-1250kw |

| Capacity |

1120-6813t/h |

| Core Advantages |

Annular cavity laminated crushing |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

III. Advantages of Choosing a Top Manufacturer

Partnering with a leading gyratory crusher manufacturer brings multi-dimensional long-term value to your project:

1. Optimized Total Cost of Ownership (TCO)

While the initial investment may be higher, significantly lower long-term operating and maintenance costs, thanks to higher equipment reliability, longer wear part lifespan, and lower energy consumption, result in a more favorable total cost of ownership.

2. Guaranteed Capacity and Product Granularity

Based on solid test data and project experience, top manufacturers can provide accurate capacity and product granularity guarantees, ensuring that equipment performance perfectly matches your production plan and reduces project risks.

3. Technological Innovation and Future Upgrades

They continuously invest in R&D, providing intelligent solutions (such as automatic control systems, wear monitoring, and predictive maintenance), and ensuring that your equipment is compatible with future technological upgrades, protecting your investment.

IV. Case Study: Our Solution as a Manufacturer

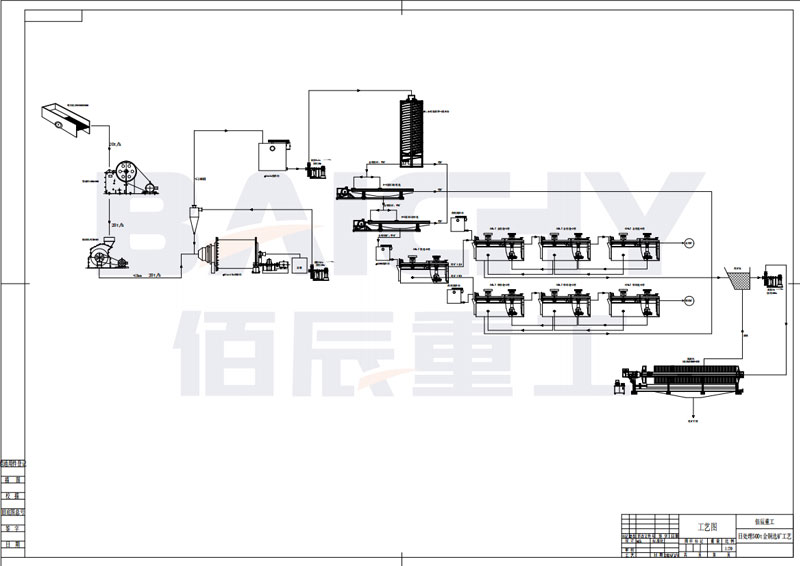

We provided a complete mobile crushing solution for a large iron ore project in Western Australia, the core of which was a large gyratory crusher designed and manufactured by us.

Challenge: The client required extremely high single-machine throughput (>2500 tons/hour) to match the mining pace and handle highly abrasive iron ore, while the equipment needed to be semi-mobile to adapt to the advancing mining face.

Our Solution: We provided a customized gyratory crusher with a specially designed cavity shape, using special alloy liners, and integrated it into a modular, semi-mobile steel structure platform. It was equipped with an intelligent lubrication system and a remote monitoring module.

Results: Since commissioning, the equipment has consistently exceeded capacity targets, and the liner lifespan has increased by 15% compared to the industry average. The intelligent system successfully warned of a potential bearing temperature anomaly, preventing unplanned downtime. This project has become a strong testament to our manufacturing capabilities.

V. Related Recommendations: Building the Best Cooperation Model

In the selection and cooperation process, we recommend that you:

Conduct factory audits: Visit the potential gyratory crusher manufacturer's production workshops, quality control processes, and R&D facilities to witness their manufacturing capabilities firsthand.

Examine reference projects: Request the manufacturer to provide successful case studies of similar working conditions and scale, and, if possible, conduct on-site visits to users to obtain firsthand operational feedback.

Focus on Life Cycle Service Agreements (LTSA): Discuss long-term service agreements with manufacturers, covering regular maintenance, priority spare parts supply, and technology upgrades, to minimize operational risks.

VI. Frequently Asked Questions (FAQ)

FAQ 1: How to choose between international major brand manufacturers and regional manufacturers?

Answer: This depends on the project scale, budget, and service requirements. Top international gyratory crusher manufacturers have deep technological expertise and extensive global support networks, making them suitable for super-large, long-life global projects. Some manufacturers specializing in specific regions or fields (such as us) may offer more flexible, responsive, and customized solutions and localized services, providing better value for money. The key is to evaluate their actual performance and service capabilities in similar working conditions for your project.

FAQ 2: Can the manufacturer provide complete line design and supporting equipment?

Answer: Leading manufacturers typically have the capability to provide complete system solutions from feeding, crushing, screening to conveying. Choosing a manufacturer that can provide "turnkey" projects or main equipment and key supporting equipment is beneficial for optimizing system compatibility and single-point responsibility, reducing interface risks.

FAQ 3: How do manufacturers typically respond to customized needs?

Answer: True top-tier gyratory crusher manufacturers should not just be sellers of standard products. They should have an engineering team capable of performing necessary customized designs based on your specific ore characteristics (hardness, abrasiveness, viscosity), target capacity, product particle size, and site limitations, including crushing chamber type, drive power, and discharge opening adjustment methods, and provide corresponding simulation reports and data support.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!