Impact Rock Crusher | Cement Plant

Impact crushers, as highly efficient crushing equipment, play a crucial role in the fine and medium crushing stages of cement production raw materials due to their unique stone-on-stone and stone-on-iron working principles. As a manufacturer of mining crushing equipment with 20 years of experience, we deeply understand the stringent requirements of cement production regarding material particle shape, gradation, and output.

Impact crushers can not only crush raw materials such as limestone, gypsum, and coal to ideal particle sizes, but their superior finished product particle shape and low needle-like/flaky content also directly improve cement firing efficiency and final product quality. This article will delve into the application advantages of impact crushers in cement plants, sharing our comprehensive solutions and global project experience.

| Key Words | Impact Rock Crusher |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

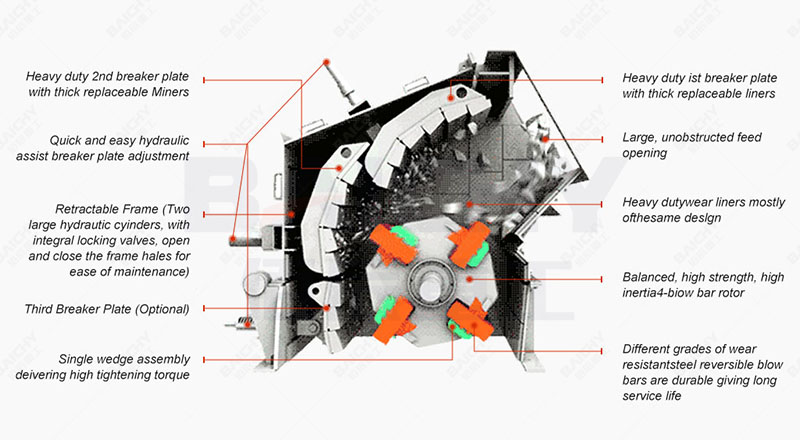

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

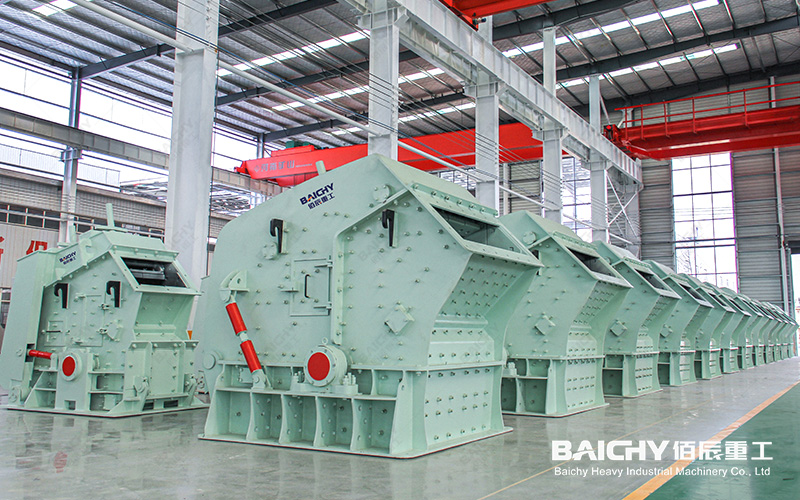

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

PF Impact Crusher Structure Diagram

Core Product Advantages

1. High Efficiency and Energy Saving, Cost Reduction and Efficiency Improvement: Utilizing advanced centrifugal impact crushing principles, the crushing ratio is large, increasing production efficiency by more than 30% compared to traditional equipment. Optimized flow channel design and the application of wear-resistant materials significantly reduce unit energy consumption and maintenance costs, helping cement plants achieve green and low-carbon production.

2. Excellent Particle Shape, Guaranteed Quality: The crushed material is cubic in shape, with uniform particle size and reasonable gradation. This excellent particle shape reduces the flow resistance of cement raw materials in the rotary kiln, improves calcination uniformity and clinker quality, and simultaneously gives the concrete higher strength.

3. High Wear Resistance, Stable Operation: Core wear-resistant components (such as the throwing head and peripheral guard plates) are made of our specially formulated high-toughness alloy composite material, ensuring a long service life and easy replacement. The overall equipment structure is robust, with low vibration, ensuring continuous and stable operation of the cement production line and reducing unplanned downtime.

4. Intelligent Adaptability for All Scenarios: We offer various models from VSI and HVI to mobile impact crushers, and can provide customized configurations based on the specific raw material characteristics (hardness, moisture content, soil content), capacity requirements (100-800 tons per hour), and spatial layout of the cement plant. The equipment integrates an intelligent monitoring system to monitor the operating status in real time, enabling predictive maintenance.

Core Application Scenarios in Cement Plants

• Fine Crushing of Limestone: Secondary crushing of blasted limestone to a suitable feed size for the raw meal mill (typically <25mm) is the most important and economical application scenario for impact crushers.

• Auxiliary Raw Material Processing: Used for crushing gypsum, shale, sandstone, etc., to obtain homogenized blends.

• Coal Preparation: Crushing lump coal to the particle size required for coal milling, ensuring stable kiln heating.

• Clinker Crushing (Optional): In some processes, used to crush small amounts of cooled clinker lumps.

• Construction Waste Recycling: Helps modern cement plants co-process construction waste, crushing it into recycled aggregate, aligning with the circular economy trend.

PF Impact Crusher Crushing Site

Global Project Case Sharing

Case Study 1: A Large Cement Group in Southeast Asia

• Challenges: Poor limestone particle shape in the existing production line resulted in low raw meal mill output and high power consumption. Limited space and limited room for modification.

• Solution: We provided them with two high-performance HVI series impact crushers, using a compact tower layout. Equipped with automatic vibration monitoring and overload protection devices.

• Results: Output particle size stabilized at 0-20mm, with needle-like and flaky content below 8%. Raw material grinding table hourly output increased by 18%, saving over one million yuan in electricity costs annually. The equipment has been operating stably for over 5 years.

Case Study 2: Central Asia Cement Production Line EPC Project

• Challenges: The project site was remote, requiring extremely high equipment reliability and ease of maintenance. Raw material moisture content fluctuated significantly.

• Solution: We provided a complete solution from design and equipment supply to installation guidance. An anti-clogging impact crusher was selected, equipped with a hydraulic opening device for rapid maintenance in harsh environments.

• Results: The entire cement production line was successfully put into operation. The crushing system demonstrated strong adaptability, operating stably even during high humidity seasons, earning high praise from the client.

Frequently Asked Questions (FAQ)

Q1: What are the differences between impact crushers, hammer crushers, and cone crushers in cement plant applications?

A1: Hammer crushers are mainly used for primary crushing (from large to small pieces), but the hammers wear quickly, resulting in generally poor particle shape. Cone crushers have good wear resistance and are suitable for crushing hard rock, but the particle shape is mostly flaky. Impact crushers produce the best particle shape of the three, making them particularly suitable for producing high-quality aggregates and improving the grindability of raw materials. They are one of the best choices for medium and fine crushing, offering both efficiency and cost advantages.

Q2: How to handle sticky limestone with high soil content and high moisture content?

A2: We offer specialized anti-clogging designs and liner structures, such as self-circulating airflow inside the vortex chamber and replaceable wear-resistant liners. In terms of process, we recommend adding a pre-screening or drying step beforehand. We will test your raw material sample and recommend the most suitable model and hammer structure.

Q3: What are the service life and replacement costs of wearing parts?

A3: Service life varies depending on the hardness of the raw material. For limestone, our specially designed throwing heads typically have a service life of 500-1200 hours. We offer modularly designed wear parts that support partial replacement, significantly reducing maintenance costs. Overseas, we have established regional spare parts warehouses to ensure rapid supply.

Q4: Do you provide an automated control system?

A4: Yes. Our equipment can be integrated with an intelligent control system to achieve remote start/stop, real-time monitoring of key parameters (vibration, temperature, current), alarms, and interlocking control with upstream feeders, helping cement plants move towards intelligent, unmanned crushing workshops.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.