Baichy Global Crushing Customer Sites

In numerous fields such as mining, construction aggregate production, and solid waste resource utilization, crushing is the first and crucial step in raw material processing. Different material characteristics, capacity requirements, and finished particle sizes necessitate different types of crushing equipment to achieve efficient and economical crushing operations. As a manufacturer of mining crushing equipment with 20 years of professional experience, we understand that there is no one-size-fits-all crusher.

Our Products and Core Advantages

We offer a full range of crushing equipment, from coarse crushing and medium crushing to fine crushing and shaping for sand making. Each product embodies twenty years of technological accumulation and innovation.

PE Jaw Crusher

• Jaw Crusher (Iron Stomach Coarse Crushing Expert): With its robust structure, deep V-shaped crushing chamber, and high crushing ratio, it is the absolute mainstay for primary crushing of large, hard ores (such as granite and basalt). Its advantages lie in reliable operation, easy maintenance, and strong adaptability.

Hydraulic Cone Crusher

• Cone Crusher (Medium and Fine Crushing Energy Saving Expert): Utilizing the principle of layered crushing, it is particularly suitable for secondary and tertiary crushing of medium to high hardness materials. Hydraulically adjustable discharge port and chamber clearing function, high degree of automation, uniform product particle size, low energy consumption, making it the first choice for those seeking high-quality aggregates and stable production.

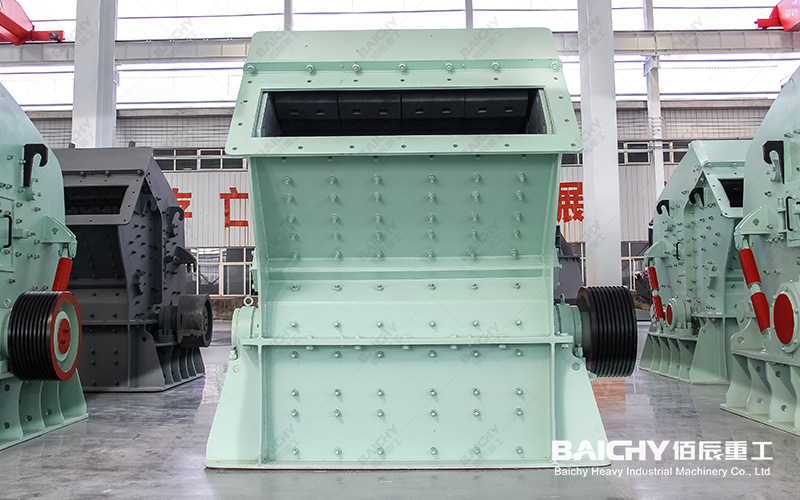

PF Impact Crusher

• Impact Crusher (High-Efficiency Shaping All-Rounder): Utilizes impact energy for crushing, suitable for medium to low hardness, non-abrasive materials (such as limestone, recycled concrete). Produces good cubic particle shape, particularly suitable for high-standard aggregates in construction. Simple structure, easy maintenance, and relatively low investment cost.

Vertical Shaft Impact Crusher/Sand Making Machine

• Impact Crusher (Vertical Shaft Impact Crusher/Sand Making Machine): Combines stone-on-stone and stone-on-iron crushing, it is the core equipment for artificial sand making and fine stone shaping. It can crush small stones into high-quality manufactured sand that meets national standards, with controllable gradation and rounded particle shape, greatly increasing product added value.

Mobile Crushing Plant

• Mobile Crushing Station (Walking Crushing Plant): Integrates single or multiple machines onto a vehicle chassis, enabling rapid relocation and on-site crushing. Especially suitable for urban construction waste treatment, small and medium-sized mining operations, and projects in remote areas, significantly reducing logistics and infrastructure costs while providing maximum operational flexibility.

Core Comprehensive Advantages:

• Full-Scenario Coverage: Mature solutions are available for everything from fixed production lines to mobile crushing plants, from multi-million-ton mines to small-scale recycling projects.

• High Reliability: Core components utilize high-quality materials and advanced processes, ensuring long-term stable operation under harsh conditions.

• Intelligence and Energy Saving: Integrated automatic control, remote monitoring, and energy-saving design help customers reduce overall operating costs.

• Global Support: Full lifecycle service is provided, from site surveys, solution design, installation and commissioning to after-sales training and spare parts supply.

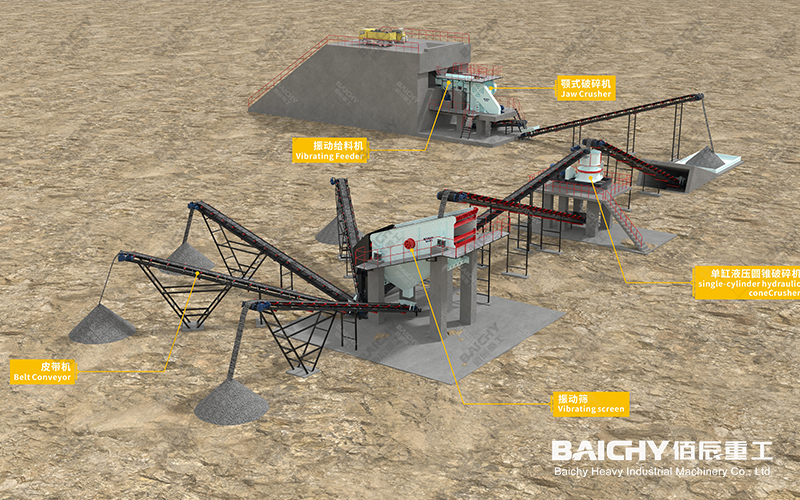

Stone crushing plant

Application Scenarios

• Large-Scale Mining: Multi-stage crushing (jaw crusher + cone crusher + sand making machine) linkage constructs an efficient and environmentally friendly modern sand and gravel aggregate production line.

• Construction Aggregate Production: Produces various grades of crushed stone and high-quality manufactured sand to meet the high-standard requirements of highways, bridges, commercial concrete, and precast components.

• Solid Waste Recycling: Crushing and sorting construction waste, concrete blocks, and waste bricks and tiles to produce recycled aggregates, achieving a circular economy.

• Metallurgy and Mining: Processing iron ore and non-ferrous metal ores to provide raw materials of suitable particle size for mineral processing.

• Infrastructure Construction Projects: Mobile crushing plants provide on-site temporary crushing solutions for highway, railway, and water conservancy projects, saving significant transportation costs.

Project Cases

• A large granite aggregate project in Southeast Asia: We designed a three-stage crushing and shaping production line with a capacity of 1200 tons per hour. The core configuration includes a large jaw crusher for primary crushing, two multi-cylinder hydraulic cone crushers for medium and fine crushing, and finally, an impact crusher for shaping and sand making. The line has been operating stably for three years, with excellent finished aggregate particle shape, widely welcomed by the local high-end building materials market.

• A construction waste recycling project in a European city: Utilizing our provided combination of a tire-mounted mobile impact crusher and a mobile screening station. The equipment can be directly deployed to demolition sites, converting construction waste into recycled aggregates of various specifications on-site for use in road subbase and new building material manufacturing. This achieves zero transportation emissions and 100% on-site resource recovery, earning local environmental awards.

FAQ

1. How to choose the right crusher type?

It mainly depends on four factors: the hardness and abrasiveness of the raw material, the feed size, and the required finished particle size and output. Our engineering team can provide free technical consultation and solution design.

2. How to choose between a stationary production line and a mobile crushing plant?

Stationary production lines are suitable for large-scale projects with stable material sources and long service cycles (several years or more), offering a high return on investment. Mobile crushing plants are suitable for short- to medium-term projects with dispersed materials, frequent relocation, or shorter project cycles, offering unparalleled flexibility.

3. Can your equipment adapt to international voltage and environmental standards?

Absolutely. We have a long history of exporting globally, and our equipment can be customized to meet the voltage, frequency (e.g., 60Hz), and stringent environmental standards (e.g., noise and dust control) of the customer's country.

4. What support do you provide after equipment delivery?

We provide detailed installation guidance, operator training, remote technical support, and timely spare parts supply. We have service centers or partners in multiple regions worldwide to ensure rapid response.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.