In the mining and stone processing industry, impact crushers, as a key piece of equipment, have become the preferred choice for many mining companies due to their high efficiency, energy saving, and excellent finished product particle shape. As a manufacturer of mining crushing equipment with 20 years of professional experience, we are committed to providing global customers with comprehensive crushing solutions for all scenarios, helping to improve the quality and efficiency of mining production.

Impact Crusher | Stone Crushers

Impact crushers, also known as impact breaker or sand making machines, utilize a high-speed rotating rotor to throw materials onto an impact plate, achieving material crushing through the stone-on-stone or stone-on-iron principle. This equipment is particularly suitable for crushing and shaping medium-hard and harder materials, and is widely used in mining, building materials, transportation, energy, and other fields. Compared to traditional jaw crushers or cone crushers, impact crushers outperform traditional crushers in terms of finished product particle shape and energy saving.

| Key Words | Secondary Impact Crusher |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

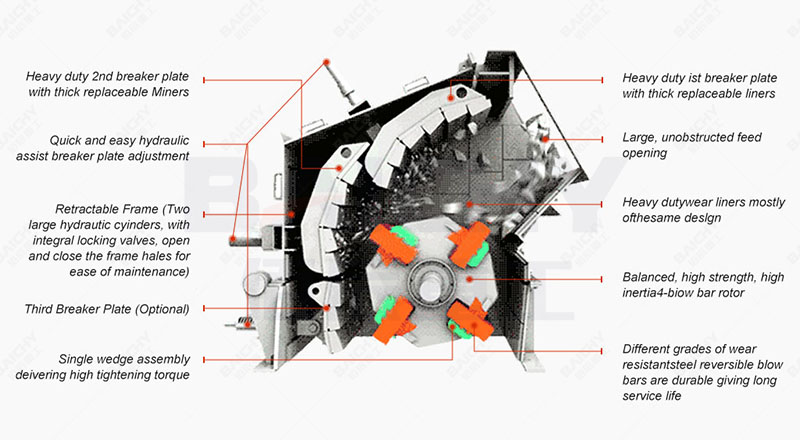

PF Impact Crusher Structure Diagram

Product Advantages

1. High Efficiency and Energy Saving: Adopting advanced crushing chamber design and rotor structure, the crushing ratio is large, production efficiency is high, and energy consumption is reduced by approximately 30%.

2. Excellent Finished Particle Shape: The crushed material is cubic in shape with low needle-like and flaky content and a reasonable gradation, making it ideal for high-standard construction aggregates.

3. Easy Maintenance: Key components are made of wear-resistant materials, ensuring a long service life. The hydraulic opening device makes maintenance more convenient.

4. Environmentally Friendly and Intelligent: The equipment operates with low noise, is equipped with a dust collection system, and can be integrated with an intelligent monitoring module for remote operation and maintenance.

5. Flexible Adaptability: Different specifications and configurations can be customized according to customer needs to meet perse production scenarios.

Application Scenarios

• Mining: Used for secondary or tertiary crushing of ores such as granite, basalt, and limestone.

• Sand and Gravel Aggregate Production: Produces high-quality manufactured sand and various specifications of construction aggregates.

• Construction Waste Recycling: Processes concrete blocks, waste bricks, tiles, and other construction waste for recycling.

• Railway and Highway Construction: Provides high-standard gradation materials for roadbeds and pavements.

• Cement Production: Used for the pretreatment of raw materials such as limestone.

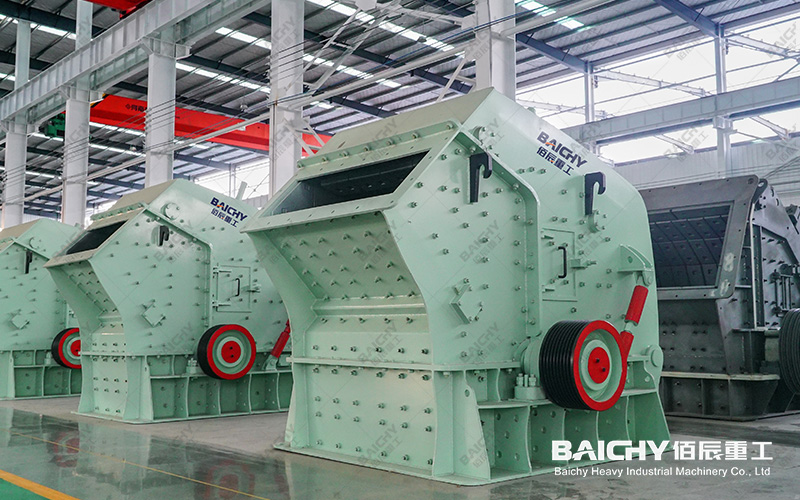

PF Impact Crusher Crushing Site

Project Cases

Case 1: A Large Granite Quarry in Southeast Asia

The client's original production line had a high content of needle-like and flaky particles in its finished products, resulting in insufficient market competitiveness. We configured two HVI-1263 impact crushers for them, increasing the production capacity to 400 tons per hour after the upgrade, with the proportion of cubic aggregate in the finished product exceeding 95%, successfully penetrating the high-end building materials market.

Case 2: A Cross-Border Highway Project in Central Asia

The project required approximately 5 million tons of high-standard road aggregate. We provided a complete system solution including feeding, crushing, screening, and dust removal, with the core equipment being three HSI-1315 impact crushers. The production line has been operating stably for 3 years, producing over 15 million tons of aggregate, ensuring the smooth progress of the project.

Frequently Asked Questions (FAQ)

Q1: What are the main differences between an impact crusher and a cone crusher?

A1: Impact crushers use impact energy for crushing, resulting in better particle shape and are suitable for medium-hardness materials; cone crushers use layered crushing, making them more suitable for high-hardness materials, but the particle shape is slightly inferior. The two are often used in combination.

Q2: What is the lifespan of the key wear-resistant parts of the equipment?

A2: We use high-chromium alloy or ceramic composite wear-resistant materials. Depending on the hardness of the material, the lifespan of vulnerable parts such as hammer plates and impact blocks is generally 200-800 hours, and quick replacement is supported.

Q3: Does it support an intelligent control system?

A3: Yes. We can provide an IoT intelligent monitoring system to monitor equipment vibration, temperature, output, and other data in real time, enabling predictive maintenance and reducing unexpected downtime.

Q4: What are the minimum and maximum discharge particle sizes?

A4: Depending on the model, the discharge particle size adjustment range is usually between 0-50mm. Precise control can be achieved by adjusting the rotor speed, impact plate gap, etc.

Q5: What support can the manufacturer provide?

A5: We provide full lifecycle services, from site survey, solution design, equipment installation and commissioning, operation training to spare parts supply and regular follow-up visits, ensuring the long-term stable operation of customer projects.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.