150 T/H Quarry Equipment Solution | Mauritius Customer

In today's globalized building materials and mining market, capacity matching is crucial for project success. When the core demand is "A Mauritian customer is looking for a quarry with a total equipment capacity of 150 tons/hour," this is not merely a simple parameter requirement, but represents the customer's precise planning for the stability, efficiency, and long-term profitability of the quarry equipment.

As a manufacturer of mining crushing and grinding equipment with 20 years of deep industry experience, we deeply understand that a well-designed quarry production line with matching capacity is the cornerstone for customers to maintain an advantage in fierce market competition.

Stone Crushing Plant PDF,Download ↓↓↓

Why is a 150-ton/hour capacity configuration so popular?

Market Analysis and Positioning

A 150-ton/hour quarry equipment capacity is the "golden ratio" for many medium-sized sand and gravel aggregate production projects and infrastructure construction. It effectively balances investment costs and output benefits, meeting the continuous supply needs of large-scale regional projects (such as housing development and road construction) while avoiding equipment idleness and financial pressure caused by overcapacity. For island markets like Mauritius, this scale perfectly matches their domestic construction and partial export needs, making it one of the best options to ensure a high return on investment.

Capacity Overview and System Composition

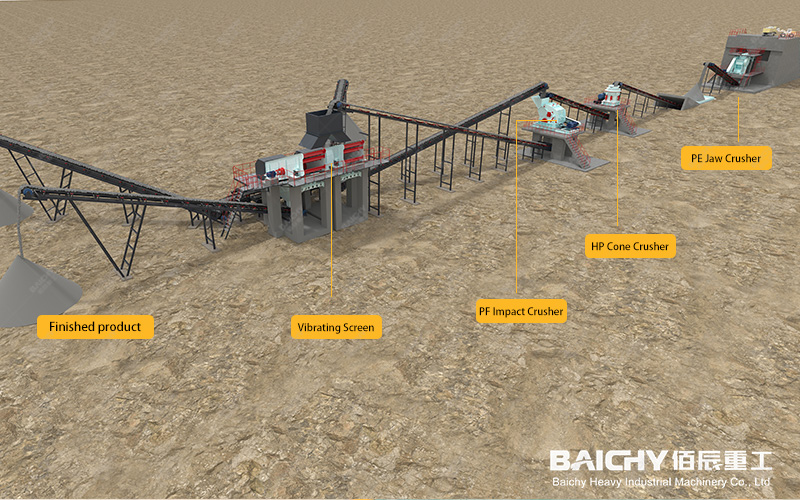

A complete 150 tonnes/hour quarry production line is not simply a collection of inpidual pieces of equipment. It is typically a collaborative system including:

• Primary crushing equipment: such as a jaw crusher, responsible for the first coarse crushing of large raw materials.

• Secondary crushing equipment: such as a cone crusher or impact crusher, for medium and fine crushing of the coarsely crushed material to achieve the required particle size.

• Screening equipment: multi-layer vibrating screens, which precisely classify the crushed material into different sizes.

• Conveying system: belt conveyors, connecting each process to ensure smooth material transport.

200tph Granite Crushing Solution

Core Advantages of Our 150 Tons/Hour Production Line

With 20 years of technical expertise and project experience, our solutions offer the following significant advantages:

Superior Reliability and Durability

As a seasoned manufacturer of mining crushing and grinding equipment, we deeply understand the importance of continuous and stable equipment operation. All core equipment utilizes high-strength materials and a heavy-duty design. Key components have been optimized to ensure durability even in high-temperature and high-humidity environments like those in Mauritius, minimizing downtime.

High Efficiency and Energy Saving, Lower Operating Costs

Our quarry equipment incorporates modern energy-saving technologies. By optimizing the crushing chamber design, transmission system, and power configuration, it significantly reduces energy consumption per ton of product while maintaining a rated capacity of 150 tons/hour, saving customers long-term operating costs.

Flexible Configuration and Intelligent Control

We offer modular designs that can be flexibly configured according to the customer's raw material properties (such as hardness and mud content), output specifications, and site conditions. Simultaneously, an intelligent control system can be equipped to achieve one-button start/stop, remote monitoring, and fault warnings, greatly simplifying operation and improving management efficiency.

Successful Case Study

We provided a complete 150-ton/hour granite quarry production line for a customer on an island in Southeast Asia with market conditions similar to Mauritius. This customer faced challenges due to hard raw materials and limited space. We configured a combination solution of a jaw crusher + cone crusher + high-efficiency screen for them. For the past three years, the equipment has maintained a stable production capacity of 150-160 tons/hour, producing products with uniform particle size that fully meets the requirements of local high-end commercial concrete plants. The customer's return on investment cycle has been shortened by approximately 20% compared to expectations.

Recommended Equipment

For customers planning to build a quarry with a capacity of 150 tons/hour, we highly recommend the following core equipment combination:

• PE-600×900 Jaw Crusher: A reliable primary crushing unit.

• HPC-200 Hydraulic Cone Crusher: Used for medium and fine crushing, producing aggregates with excellent particle shape.

• 3YK-2160 Vibrating Screen: For efficient screening and grading.

This combination, with its high cost-effectiveness and low wear characteristics, has become a classic configuration for medium-sized quarries worldwide.

Frequently Asked Questions (FAQ)

1. How long does it typically take from signing the contract to the 150 tons/hour production line being operational in Mauritius?

This depends on the specific configuration and complexity of the production line. Generally, the total cycle from design, production, shipping to installation and commissioning is approximately 4-6 months. We will provide a detailed project timeline and ensure close coordination at every stage.

2. How do you guarantee after-sales service and spare parts supply for overseas customers?

We establish lifetime files for all exported equipment and provide remote video technical support. For overseas customers such as Mauritius, we have authorized service partners locally and establish common spare parts warehouses in major ports to ensure that key components can be delivered quickly within 7-15 days, eliminating your concerns.

3. If it is necessary to adjust the specifications of the final product (such as simultaneously producing crushed stone and manufactured sand), can this equipment achieve this?

Absolutely. Our 150 tons/hour production line is designed with high flexibility. By adjusting the discharge port of the crusher, changing the screen specifications, or adding a sand making machine module, the output ratio of different specifications of gravel and manufactured sand can be flexibly adjusted without affecting the main line capacity, maximizing product value.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!