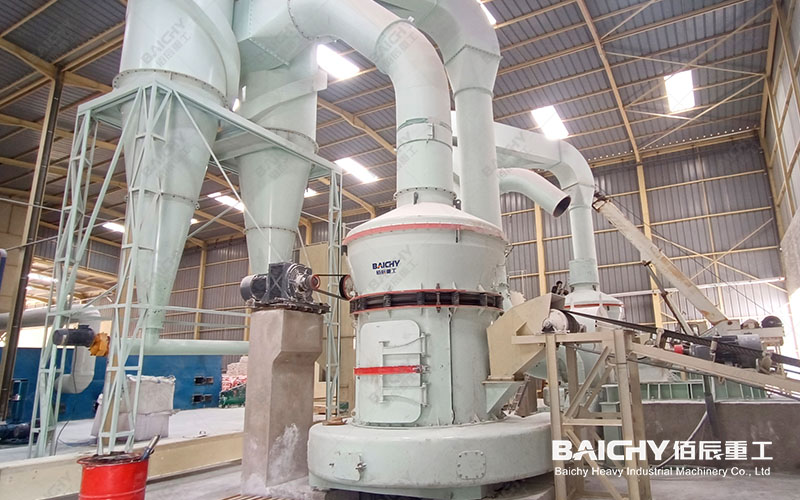

Dolomite grinding mill

In numerous industrial fields such as ceramics, glass, rubber, and coatings, the demand for high-quality dolomite powder with a fineness of 325 mesh (approximately 44 μm) and below is growing rapidly. Faced with the goal of large-scale production of at least 10 tons per hour, many business owners and engineers are seeking a perfect solution that balances efficiency, stability, and energy consumption.

Today, as a manufacturer of mining crushing and grinding equipment with twenty years of profound technical expertise, we will delve into how to build a dolomite powder production line that meets or even exceeds these requirements.

| Product Model | Raymons Grinding Mill |

|---|---|

| Maximum Feed Size | 0-25 mm |

| Processing Capacity | 0.5-60tph |

| Motor Power | 7.5-75 kW |

| Core Structure | Grinding and classification integrated system |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. Core Demand Analysis: The Triple Challenge of Fineness, Output, and Stability

First, we must clarify the technical implications behind the 325 mesh and below, 10 tons per hour standard:

• Fineness Requirement: 325 mesh is a watershed, marking the entry into the fine powder category. This means the equipment must possess powerful grinding capabilities, not just simple crushing.

• Output Requirement: 10 tons per hour (i.e., over 240 tons per day) is a significant large-scale production indicator, requiring the main equipment to have a strong throughput and processing capacity, and the entire system process must be smooth and continuous.

• Implicit Requirements: In addition to meeting the above two points, the long-term stability of equipment operation, the service life of wear parts, the energy consumption per unit of product (electricity consumption), and the concentration of finished product particle size (classification efficiency) are also key factors determining the return on investment.

Raymond grinding mill

II. Raymond Mill (Vertical Roller Mill) is the Ideal Choice

For dolomite, a non-metallic mineral with medium hardness and good grindability, to achieve large-scale grinding at the 325 mesh level, large Raymond mills (or upgraded high-pressure suspension roller mills, European-style mills) are currently the most mature and cost-effective option on the market.

Compared with traditional ball mills, modern Raymond mill systems have advantages in fineness range and energy consumption. Its working principle is to crush the material through the rotating grinding rollers and grinding rings, and the built-in high-efficiency classifier separates the qualified fine powder in real time. The system has a high degree of integration, enabling automated continuous operation from raw material feeding to finished product collection and packaging.

Why does it perfectly match your needs?

1. Precise and Controllable Fineness: By adjusting the classifier speed, the fineness of the finished product can be easily and flexibly adjusted between 80-400 mesh, with stable production of 325 mesh products being effortless.

2. Fully Compliant Production Capacity: Choosing the 5R or 6R large-scale Raymond mill model, its single-machine hourly output can fully cover the range of 10-25 tons, providing a solid guarantee for your target output, and even leaving room for increased production.

3. Economical Energy Consumption: Compared with traditional processes, its grinding principle ensures higher energy utilization efficiency and lower unit power consumption.

4. Stable and Reliable Operation: The structure has been optimized over decades, and the core transmission components are robust and durable, suitable for 24-hour continuous industrial production. This is the reliability proven by our twenty years of experience.

III. More Than Just a Grinding Mill, It's a Complete Solution

In an efficient production line, the main machine is the heart, but the supporting systems are equally vital. The typical process flow we design for you is as follows:

1. Primary Crushing (if needed): If the raw material is in large lumps, a jaw crusher can be used for coarse crushing to ensure uniform particle size of the material entering the mill (usually ≤30mm), which is a prerequisite for stable and high output.

2. Feeding and Conveying: Using an electromagnetic vibrating feeder combined with a closed screw conveyor, uniform, quantitative, and dust-free feeding is achieved, protecting the working environment.

3. Core Grinding and Classification: As mentioned above, a large-scale Raymond mill is used as the main machine, and its built-in high-precision turbine classifier is key to ensuring the qualification rate of 325 mesh products.

4. Finished Product Collection and Dust Removal: A pulse bag dust collector is used as the finished product collection device. It is not only an environmentally friendly dust removal device but also an efficient finished product collection system, with a collection efficiency of over 99.9%, ensuring no loss of output and achieving clean production.

5. Automation Control (Upgrade Option): A PLC electrical control system can be configured to monitor key parameters such as main machine current, fan flow, and temperature in real time, enabling one-button start and stop and fault alarms, significantly reducing reliance on manual labor and operational risks. IV. Added Value Beyond the Equipment Itself

Choosing an experienced manufacturer means you get more than just a set of steel equipment:

• Customized Process Solutions: Based on your specific raw material characteristics (moisture content, impurity levels), site conditions, and investment budget, we will provide an optimized production line layout and equipment list.

• Core Component Guarantee: Wear-prone parts such as grinding rollers, grinding rings, and scraper blades are made of high-chromium alloy or wear-resistant steel composite materials. Through our unique process strengthening treatment, their service life is extended by 30%-50%, saving you maintenance costs in the long run.

• Full Lifecycle Service Support: From foundation drawings, installation guidance, and operation training to rapid spare parts supply and remote technical support, our 20-year global service network is your lifetime insurance for stable project operation.

Achieving the production target of 10 tons per hour of dolomite powder below 325 mesh is a systems engineering project. The key lies in selecting core equipment with the correct technical route, matching models, and high reliability, and building a coordinated process system. With our twenty years of focus and experience in the field of mining crushing and grinding, we have provided successful solutions to countless customers worldwide. We can not only provide equipment that meets your parameter requirements, but also deliver a high-yield, stable, energy-efficient, and worry-free production line for wealth creation.

Contact us today to get your exclusive dolomite powder production line planning scheme and return on investment analysis!

Further reading:

How To Choose A Suitable Industrial Grinding Mill?

Which Is Better Cement Vertical Roller Mill Or Ball Mill?

What Are the Differences between Dry and Wet Type Ball Mill?