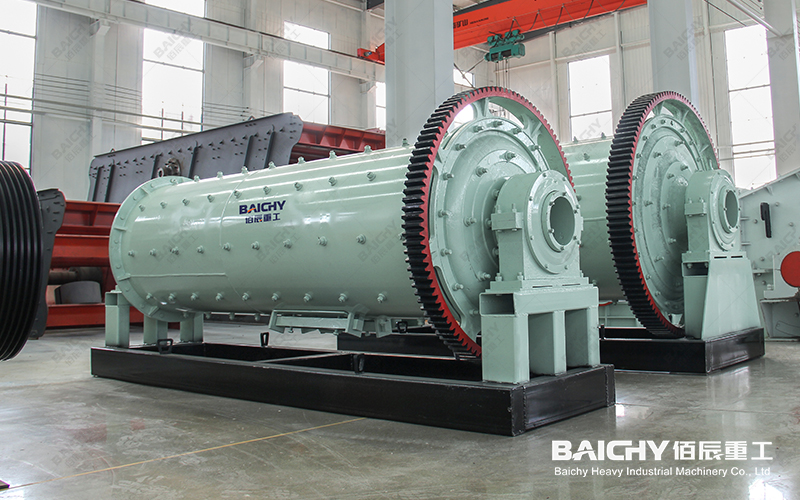

Specification of Wet Ball Mill

As a mineral processing equipment manufacturer with 20 years of experience, we understand that wet ball mill specifications are one of the most crucial concerns for customers when purchasing equipment. Choosing the right specifications can significantly improve efficiency; choosing the wrong specifications can lead to a series of problems such as insufficient capacity, excessive energy consumption, or substandard products. This article will provide an in-depth analysis of the specifications and parameters of wet ball mills to help you make informed decisions.

| Key Words | Specification of Wet Ball Mill |

|---|---|

| Product Model | Ball Mill |

| Feed Size | ≤25mm |

| Motor Power | 18.5-4500kw |

| Capacity | 0.65-615t/h |

| Core Functions | Grinding precision and particle size controllability |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. Wet Ball Mill Specifications: More Than Just Diameter and Length

Many customers may initially focus only on the diameter and length of the mill cylinder when looking at specifications. However, a complete wet ball mill specification system is a set of parameters that collectively determine the equipment's performance, capacity, and applicability.

Key Specification Parameter Analysis

• Mill Dimensions: Usually expressed as diameter × length (e.g., Φ2.7 × 3.6m). This is the basis for determining the mill's processing capacity and material grinding time. The diameter affects the lifting height and impact force of the steel balls, while the length affects the material residence time and grinding fineness.

• Effective Volume: The actual space (unit: m³) within the mill available for grinding material, directly related to the feed rate.

• Processing Capacity: The throughput (t/h) per unit time under specified feed particle size, product fineness, and specific media conditions. This is one of the most important performance indicators provided by mineral processing equipment manufacturers.

• Motor Power: The power (kW) required to drive the entire mill, affecting energy consumption and grinding intensity.

• Rotation Speed: Usually expressed as a percentage of the critical speed, affecting the movement of the steel balls and materials, and thus grinding efficiency.

• Feed and Discharge Particle Size: The maximum feed size and achievable product fineness range designed for the equipment.

Specification of Wet Ball Mill

II. Choosing the Right Specifications: Core Advantages and Considerations

Correctly matching specifications maximizes the inherent advantages of wet ball mills.

Core Advantages of Wet Grinding Process

Compared to dry grinding, wet ball mills are more widely used in mineral processing. Their main advantages are: high grinding efficiency, less dust pollution, easy adjustment of product fineness, and good flowability for easy conveying. The prerequisite for fully realizing these advantages is correct specification selection.

Selection Considerations

When selecting specifications, the following must be considered comprehensively:

1. Ore properties: hardness, density, grindability, feed particle size.

2. Production requirements: target capacity, product fineness (percentage of -200 mesh content).

3. Process flow: open-circuit or closed-circuit grinding? What are the subsequent classification equipment?

4. Plant conditions: installation space, power grid capacity, water supply.

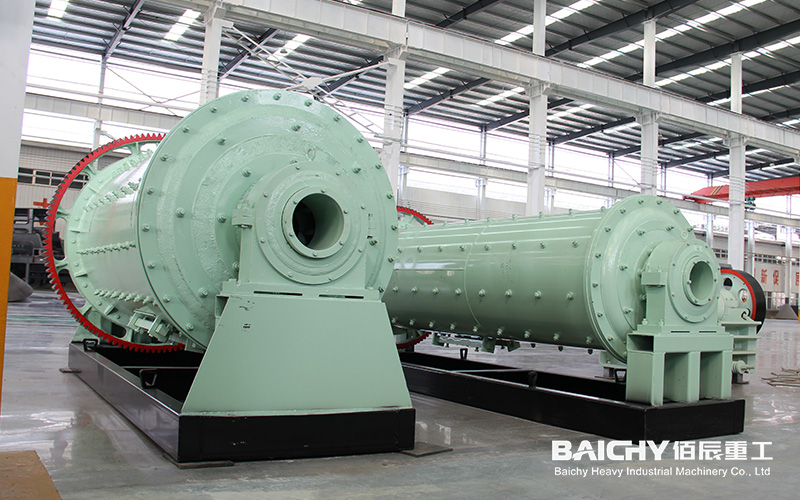

Large ball mill customer site

III. Classic Case: How to Match Specifications to Actual Needs

We once provided a solution for a copper mine beneficiation plant in Jiangxi. The client required a raw ore processing capacity of 1500 tons per day, with a product fineness of -200 mesh accounting for 75%. After ore grindability tests and detailed calculations, we recommended a Φ3.2×4.5m wet ball mill equipped with a 400kW motor. This equipment specification perfectly matches the customer's production capacity requirements, with approximately 10% spare capacity for future expansion. It also forms an efficient cycle with the supporting classification equipment, ultimately helping the customer consistently achieve their production targets. This fully demonstrates the importance of precise specification matching by a professional mineral processing equipment manufacturer.

IV. Recommended Related Equipment: Building an Efficient Grinding System

Wet ball mills rarely operate alone. An efficient grinding system typically includes:

• Jaw crusher/cone crusher: Provides the appropriate feed particle size for the ball mill.

• Spiral classifier or hydrocyclone: Performs particle size classification, forming a closed-circuit grinding system.

• Slurry pump: Transports the slurry.

• Feeder and electrical control system: Enables stable, automated feeding and control.

V. Frequently Asked Questions (FAQ)

Q1: The specifications for a wet ball mill, Φ2.1×3.0m and processing capacity 8-45t/h, seem to have a wide range. How do I determine my actual output?

A1: The throughput range depends on multiple variables such as ore hardness, feed particle size, and output fineness. Softer ores, coarser feed, and coarser products result in output approaching the upper limit; conversely, output approaches the lower limit. The most accurate way is to provide us with ore samples for testing and analysis, and we will provide a precise expected output.

Q2: Does a higher motor power always mean better grinding performance?

A2: Not necessarily. Motor power needs to be scientifically matched with the cylinder size and load capacity. Insufficient power will lead to insufficient power and weak grinding; excessive power will result in energy waste and increased unnecessary operating costs. Mineral processing equipment manufacturers design their systems precisely to ensure optimal power-to-specification matching.

Q3: I want to increase the capacity of my existing production line. Is it more economical to replace it with a larger ball mill or to add another one?

A3: This requires specific analysis. If site space and infrastructure allow, replacing it with a larger machine usually results in higher system integration. However, if space is limited, or if you want to maintain the flexibility of the existing production line, adding a smaller machine to form a parallel production line may be the preferred solution. Our engineers can provide a detailed comparison of options.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.