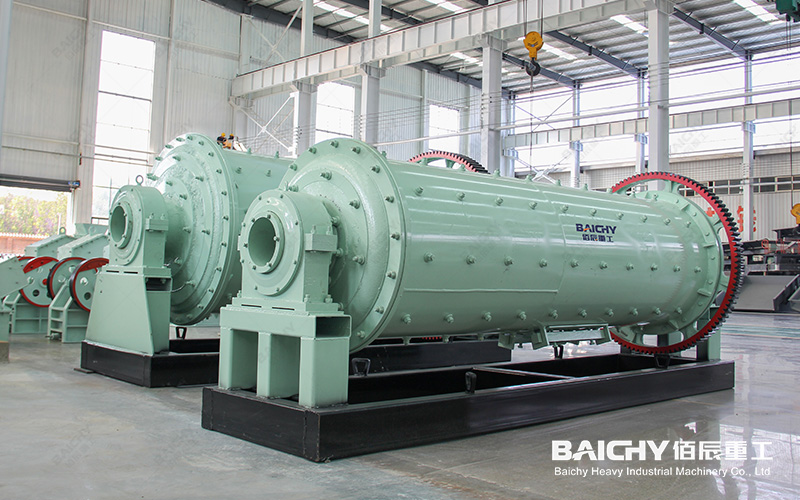

Industrial Wet Ball Mill Machine for Mineral Grinding

As a mineral processing equipment manufacturer with 20 years of experience, we deeply understand that the grinding process is crucial in determining the final product particle size, recovery rate, and economic benefits in mineral processing. Among various grinding equipment, the industrial wet ball mill plays an indispensable role due to its unique advantages. This article will provide an in-depth analysis of this equipment, sharing our professional insights and practical experience.

| Key Words | Industrial Wet Ball Mill Machine for Mineral Grinding |

|---|---|

| Product Model | Ball Mill |

| Feed Size | ≤25mm |

| Motor Power | 18.5-4500kw |

| Capacity | 0.65-615t/h |

| Core Functions | Grinding precision and particle size controllability |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Overview of Industrial Wet Ball Mills

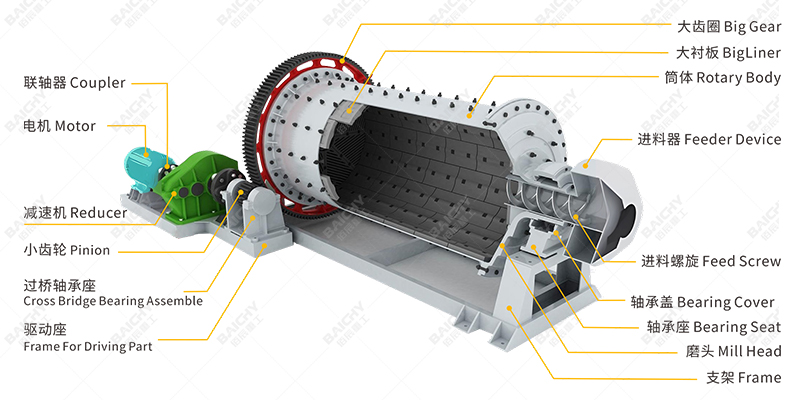

The industrial wet ball mill is a widely used grinding equipment in the mineral processing industry. Its working principle utilizes the rotation of the cylinder to drive the internal grinding media (usually steel balls) to impact and grind the material. Unlike dry ball mills, wet ball mills add water or other liquids during the grinding process to form a slurry. This not only facilitates material flow and discharge but also prevents dust from flying and, in some cases, improves grinding efficiency and product fineness.

Internal structure diagram of ball mill

Core Advantages of Wet Ball Mills in Mineral Grinding

Why is wet grinding so favored in the field of mineral grinding? This stems from its multifaceted technological advantages.

Higher Grinding Efficiency and Finer Product Particle Size

The presence of water acts as a lubricant and dispersant, carrying away fine particles, reducing over-grinding, and continuously exposing the surface of fresh material, thereby improving grinding efficiency. It is particularly suitable for processing minerals requiring subsequent wet processes such as flotation and leaching, easily achieving the required fineness.

Excellent Environmental Friendliness and Working Environment

The wet ball milling process generates virtually no dust, greatly improving the workshop working environment, protecting employee health, and meeting increasingly stringent environmental protection requirements. It also reduces the risk of dust explosions, resulting in higher safety.

More Stable Operation and Relatively Low Noise

The slurry provides a buffering effect on the cylinder and liners, resulting in relatively stable equipment operation and lower mechanical noise compared to dry ball mills of similar specifications. Furthermore, its smooth discharge method facilitates closed-loop circulation with downstream classification equipment (such as spiral classifiers and hydrocyclones).

Successful Application Case Sharing

In our 20 years of service experience, we have provided reliable industrial wet ball mill solutions for numerous projects worldwide.

Case Study 1: A Large Iron Ore Beneficiation Plant

This plant uses our MQY3660 large-scale wet grate ball mill for coarse grinding of iron ore. When used in conjunction with classification equipment, the processing capacity consistently reaches 280 tons per hour, with product particle size meeting the process requirement of -200 mesh accounting for 75%. The equipment uptime exceeds 94%, achieving the client's goal of stable and high production.

Case Study 2: An Overseas Copper-Molybdenum Ore Beneficiation Project

Addressing the high hardness and fineness requirements of this ore, we provided an overflow-type wet ball mill and optimized the shape of the liner lifting bars and the grinding media ratio. Ultimately, while maintaining fineness, unit energy consumption was reduced by approximately 8%, gaining high praise from the client.

How to Choose and Maintain: Our Professional Advice

Choosing a suitable wet ball mill is not just about price; it requires comprehensive consideration of ore properties (hardness, density, particle size), processing capacity, target fineness, plant configuration, and investment budget.

1. Type Selection: Grate-type forced discharge mills offer high output and minimal over-grinding, suitable for coarse grinding; overflow-type free discharge mills have a simpler structure and produce finer grinding, suitable for fine grinding or two-stage grinding.

2. Key Components: Pay attention to the liner material (e.g., high manganese steel, rubber, magnetic liners) and steel ball ratio, as these directly affect wear, lifespan, and grinding effect.

3. Professional Maintenance: Regularly inspect fasteners and the lubrication system, monitor the main bearing temperature, and add steel balls and replace liners promptly according to wear conditions. This is the cornerstone of ensuring long-term stable operation of the equipment.

Overall detail of the ball mill

Frequently Asked Questions (FAQ)

Q1: What is the main difference between wet and dry ball mills? How to choose?

A1: The core difference lies in the grinding media and environment. Wet mills use water, while dry mills use air. The choice depends on the subsequent processes: if the subsequent process is flotation or hydrometallurgy, a wet mill must be used; if the subsequent process is dry beneficiation (such as dry magnetic separation) or for products with strict moisture limits, a dry mill should be used. Wet mills generally have advantages in efficiency, environmental friendliness, and fineness.

Q2: Is the energy consumption of a wet ball mill very high? What are some energy-saving methods?

A2: Ball mills are indeed major energy consumers in mineral processing plants, but energy savings can be effectively achieved through various methods. These include: using high-efficiency energy-saving motors, using frequency converters to control the speed, optimizing the shape and ratio of grinding media, using rubber liners to reduce the equipment's weight, and maintaining a reasonable slurry concentration and feed particle size.

Q3: What could be the cause of abnormal noise from the mill cylinder during operation?

A3: Possible causes include: 1) Loose or broken liner bolts; 2) Severely worn or detached liners; 3) Poor meshing or insufficient lubrication of the gears; 4) Failure of bearings or transmission components. The machine should be stopped immediately for inspection to eliminate potential safety hazards.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.