How to Choose a Rock Crusher?

In mining, aggregate production, and infrastructure construction, crushers are core crushing equipment, and their correct selection directly impacts production efficiency, operating costs, and project benefits.

As a manufacturer of mining crushing equipment with 20 years of professional experience, we understand that making the best choice among numerous types and parameters of crushers is no easy task. This article aims to provide you with a comprehensive and professional crusher selection guide, drawing on our global project experience, to ensure you find the most suitable solution for your specific scenario.

| Key Words | How to Choose a Rock Crusher |

|---|---|

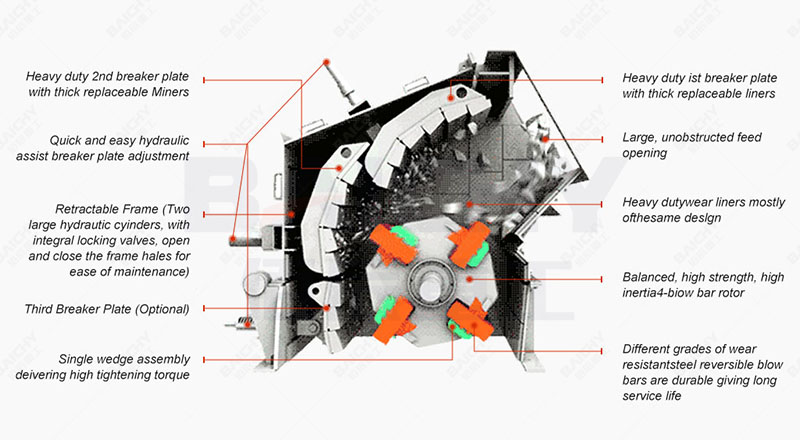

| Product Model | PF Impact Crusher |

| Feed Size | ≤700mm |

| Motor Power | 45-355kw |

| Capacity | 15-800t/h |

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

I. Core Overview of Crusher Selection: There is no best, only the most suitable

Choosing the right crusher is not simply a matter of comparing prices or specifications; it is a systematic project that requires comprehensive consideration of multiple factors, including material characteristics, capacity requirements, output specifications, site conditions, and investment budget. Incorrect selection can lead to low production efficiency, excessive wear on vulnerable parts, substandard product particle shape, and even frequent equipment failures. Successful selection, on the other hand, maximizes production efficiency, optimizes operating costs, and continuously improves return on investment.

PF Impact Crusher Structure Diagram

II. Our Product Advantages: 20 Years of Craftsmanship, Comprehensive Solutions

As a seasoned equipment manufacturer, we offer more than just machines; we provide comprehensive solutions based on our deep technological expertise.

1. Full Product Line: We offer a complete series of equipment from coarse to fine crushing, including jaw crushers, cone crushers, impact crushers, impact crushers (sand making machines), and mobile crushing plants, meeting all crushing needs from hard granite and basalt to medium-hard limestone and construction waste.

2. Advanced Technology and Stable Structure: Optimized crushing chamber design, heavy-duty rotor design, and high-performance materials ensure stable operation under high loads, high crushing efficiency, and long wear part life.

3. Intelligent Control and Energy Saving & Environmental Protection: Integrated intelligent control system enables automatic adjustment, overload protection, and fault diagnosis. The equipment design emphasizes low noise and low dust, meeting stringent global environmental standards.

4. Strong Customization Capabilities: We can provide customized solutions and process designs based on customers' specific materials, site limitations, and product requirements.

5. Global Service Network: A global after-sales service system provides full lifecycle support, from installation and commissioning, operation training, spare parts supply, and regular inspections.

III. Key Application Scenarios and Equipment Matching Recommendations

1. Primary Crushing (Coarse Crushing) in Large Mines

◦ Scenario: Processing large chunks of raw ore (particle size up to 1 meter or more) transported directly from the mine.

◦ Preferred Equipment: Jaw crusher or gyratory crusher. The former has a simple structure, is easy to maintain, and is highly adaptable; the latter has a larger processing capacity and is suitable for extra-large mines.

2. Aggregate Processing and Secondary/Tertiary Crushing (Medium/Fine Crushing)

◦ Scenario: Further crushing the coarsely crushed material into aggregates required for construction (e.g., 12-13mm, 19-25mm, etc.).

◦ Preferred Equipment: Cone crusher (suitable for medium-to-high hardness materials, prioritizing low wear costs) or impact crusher (suitable for medium-to-low hardness materials, prioritizing excellent particle shape, and capable of shaping crushing).

3. Manufactured Sand Production (Sand Making)

◦ Scenario: Crushing small-sized stones into high-quality manufactured sand (0-5mm).

◦ Preferred Equipment: Virtual Impact Screwdriver (VSI). Its "stone-on-stone" and "stone-on-iron" principles produce high-quality manufactured sand with rounded particle shapes and reasonable gradation, greatly increasing product added value.

4. Construction Waste Resource Utilization

◦ Scenario: Crushing and recycling demolished concrete and asphalt blocks in urban renewal projects.

◦ Preferred Equipment: Mobile Impact Crusher. Equipped with functions such as pre-screening, iron removal, and light material separation, it is mobile and flexible, allowing direct operation at demolition sites, turning waste into treasure.

5. Special Materials and Complex Sites

◦ Scenario: Narrow sites, frequent relocation, or handling sticky and wet materials.

◦ Preferred Equipment: Wheeled/tracked mobile crushing and screening station. Integrating feeding, crushing, screening, and conveying, this system requires no concrete foundation, allows for rapid deployment, and is an ideal choice for flexible production.

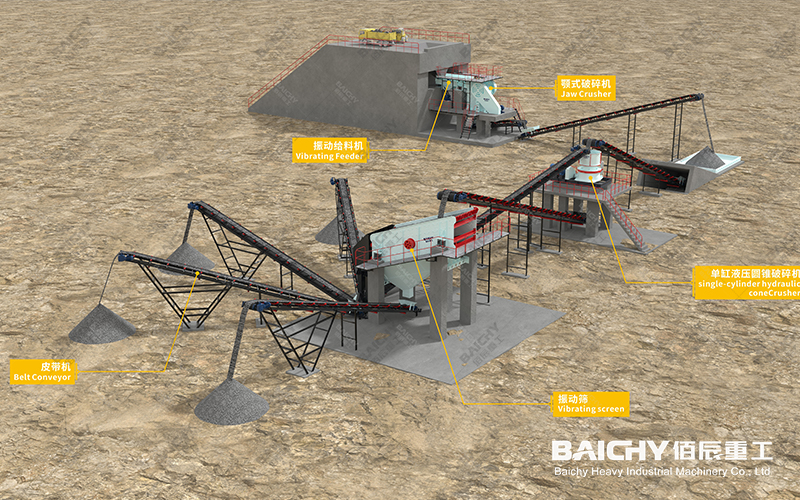

Aggregate crushing plant

IV. Global Project Case Studies

• Large-scale granite quarry in Southeast Asia: A fixed production line consisting of a jaw crusher, cone crusher, and sand making machine was installed, with an hourly output of 1200 tons. The produced aggregates and manufactured sand meet local high-standard construction requirements, and the equipment has been operating stably for over 5 years.

• Central Asian iron ore project: For extremely hard and highly abrasive iron ore, we provided a specially designed heavy-duty jaw crusher and a multi-cylinder hydraulic cone crusher. Key components utilize ultra-wear-resistant materials, significantly reducing downtime for maintenance.

V. Frequently Asked Questions (FAQ)

Q1: What is the main difference between a jaw crusher, cone crusher, and impact crusher?

A1: The core difference lies in the crushing principle and application stage. Jaw crushers are mainly used for the first stage of coarse crushing, employing the compression principle; cone crushers are mostly used for medium and fine crushing of hard rock, employing layered crushing and offering good wear resistance; impact crushers are used for medium and fine crushing of medium and soft rock and recycled materials, employing impact crushing, resulting in good particle shape, but with relatively high wear.

Q2: Should I choose a stationary production line or a mobile crushing plant?

A2: Stationary production lines have lower investment, higher capacity, and lower operating costs, making them suitable for long-term, large-scale projects with stable sites. Mobile crushing plants have higher investment but unparalleled flexibility, making them suitable for projects with short cycles, requiring relocation, or located in dispersed areas or complex terrain.

Q3: How can I ensure the stability of the output particle size?

A3: Besides the performance of the equipment itself, the key lies in the "more screening, less crushing" process design. Properly configuring screening equipment before and after crushing to form a closed-loop cycle, timely screening of qualified materials, and re-crushing only materials exceeding the standards, can significantly improve efficiency and control particle size.

Q4: How should I view the price and long-term value of the equipment?

A4: The initial purchase price is only a part of the total cost of ownership (TCO). Greater attention should be paid to the equipment's reliability, energy consumption, lifespan of vulnerable parts, and ease of maintenance. The long-term operational benefits and maintenance cost savings generated by a high-quality, low-failure-rate piece of equipment often far outweigh the initial price difference.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.