PF1007 Impact Crusher | High-Efficiency Stone Crushing Solution

In the mining and construction industries, efficient stone crushing is a crucial link in the production chain. As a manufacturer of mining crushing equipment with 20 years of professional experience, we are committed to providing reliable and efficient crushing solutions for all scenarios to our global customers.

Today, we will introduce in detail one of our star products—the PF1007 impact crusher. This machine, with its excellent performance, stable operation, and wide range of applications, has become the preferred equipment for many projects.

| Key Words | PF1007 Impact Crusher |

|---|---|

| Product Model | PF Impact Crusher |

| Feed Size | ≤250mm |

| Motor Power | 45kw |

| Capacity | 15-60t/h |

| Core Design | The heavy-duty rotor has high inertia, enabling it to crush harder materials and operate more smoothly. |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Product Overview

The PF1007 impact crusher is a medium-sized crushing device that utilizes impact energy to crush materials. It uses a high-speed rotating rotor to impact the material, causing collisions and friction within the crushing chamber, thereby achieving the crushing effect. This equipment has a compact structure and is easy to operate, making it particularly suitable for crushing medium-hardness materials such as limestone, granite, and basalt. The PF1007 not only has a large crushing ratio and uniform product particle size, but also low energy consumption and convenient maintenance, making it an ideal choice for improving production efficiency and reducing operating costs.

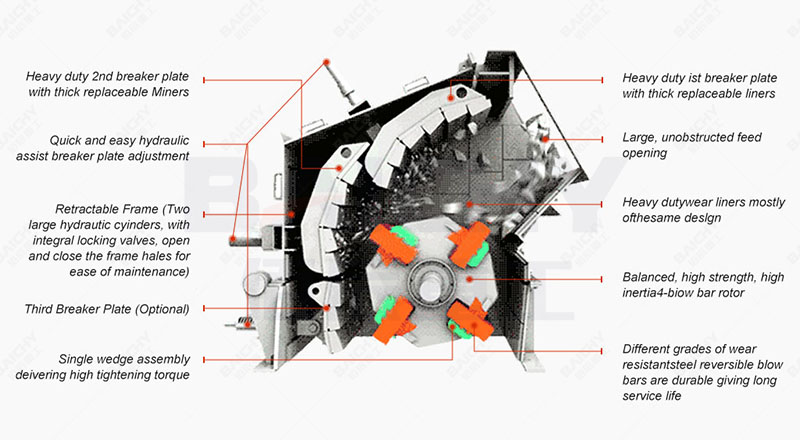

PF Impact Crusher Structure Diagram

Product Advantages

1. High Efficiency and Energy Saving: The PF1007 adopts advanced impact crushing principles, increasing crushing efficiency by over 30% compared to traditional equipment while reducing energy consumption by 20%, helping customers achieve green production.

2. Durable and Reliable: Key components such as the rotor and hammers are made of highly wear-resistant materials, ensuring a long service life and reducing replacement frequency and downtime.

3. Flexible Adaptability: The equipment features a compact design, is easy to install and move, and can adapt to different site conditions; the output particle size is adjustable to meet perse production needs.

4. Intelligent Control: An optional intelligent monitoring system can be equipped to monitor equipment operating status in real time, enabling fault warnings and remote management, improving operation and maintenance efficiency.

5. Environmentally Friendly and Low Noise: The enclosed structure design effectively reduces dust and noise pollution, meeting international environmental standards and suitable for areas with high environmental requirements.

Application Scenarios

The PF1007 impact crusher is suitable for various stone crushing scenarios, including:

• Mining: Used for primary or secondary crushing of raw ore or rock.

• Construction Aggregate Production: Crushing limestone, granite, etc., to produce sand and gravel aggregates for construction.

• Highway and Railway Construction: Providing high-quality roadbed materials to meet infrastructure construction needs.

• Cement Production: Crushing raw materials such as limestone to improve the overall efficiency of cement production lines.

• Urban Construction Waste Recycling: Processing waste concrete, bricks, etc., to achieve resource recycling.

PF Impact Crusher Crushing Site

Project Cases

We have successfully delivered hundreds of PF1007 impact crushers globally. Below are two typical case studies:

• A large limestone mine project in Southeast Asia: The client needed to efficiently process large quantities of limestone. We provided a crushing line consisting of three PF1007 crushers, with a daily output of 5,000 tons. The equipment operated stably, helping the client increase capacity by 40% and reduce maintenance costs.

• A highway construction project in South America: The project required high-quality sand and gravel aggregates. We customized a mobile PF1007 solution. The equipment was quickly deployed on-site, producing uniform particle size, ensuring project progress, and receiving high praise from the client.

Frequently Asked Questions (FAQ)

Q: What is the maximum feed size and discharge particle size range of the PF1007?

A: The maximum feed size is 350mm, and the discharge particle size is adjustable between 0-50mm, depending on the material properties and configuration.

Q: Is the equipment difficult to maintain? How often should it be maintained?

A: Maintenance is simple; daily checks only require lubrication and fasteners. A full maintenance is recommended every 500 hours of operation. We provide a detailed manual and remote support.

Q: Is it suitable for high-hardness materials such as granite?

A: Yes, the PF1007 is designed for medium to high hardness materials, but it is recommended to adjust the rotation speed and hammer type according to the actual material characteristics to optimize service life.

Q: Do you support customized needs, such as mobile configurations?

A: Of course! We offer flexible customization services, including mobile, dustproof, or cryogenic versions to adapt to different environments and project requirements.

Q: What about delivery time and after-sales support?

A: The standard equipment delivery time is 30-45 days. We provide globalinstallation guidance, training, and 24/7 online technical support to ensure the equipment continues to operate efficiently.

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.