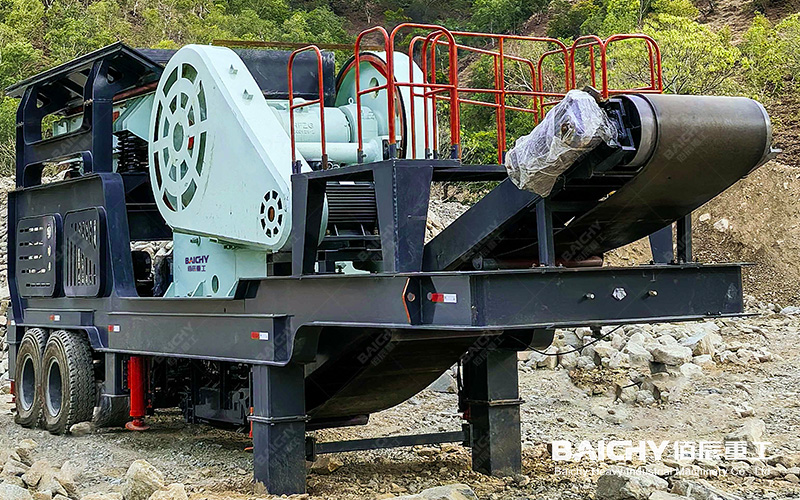

Mobile stone crusher

Faced with a dazzling array of crushing equipment on the market, how can you make an informed choice and avoid investment mistakes? This article will provide a step-by-step analysis from an expert's perspective, combining industry insights and marketing acumen.

I. Needs First: Define Your Crushing Objectives

Before selecting any equipment, a clear self-assessment is the first step. This is not just general talk, but requires precise quantification:

• Material Characteristics: Do you need to crush granite, limestone, river pebbles, or construction waste? Hardness, abrasiveness, moisture content, and feed size are key parameters.

• Capacity Requirements: What is your expected hourly or daily output? This not only concerns current needs but also requires reserving space for future development.

• Finished Product Specifications: Is the final product high-quality aggregate for high-standard commercial concrete or ordinary stone for roadbed filling? The required particle shape and gradation directly affect equipment selection.

• Operating Site and Environment: Fixed production line or mobile crushing plant? What are your specific environmental requirements (e.g., dust, noise)?

II. Core Showdown: A Comprehensive Analysis of Mainstream Crushing Equipment Technologies

Different crushing principles are suitable for different crushing stages (coarse crushing, medium crushing, fine crushing) and material properties. The following is an in-depth comparison of mainstream equipment:

| Equipment Type | Core Crushing Principle | Best Applicable Materials | Key Advantages | Considerations | Typical Application Scenarios |

| Jaw Crusher | Extrusion Crushing | High hardness, medium to high abrasive materials (e.g., granite, basalt) | Robust structure, strong ability to handle large materials, relatively simple maintenance, lower investment cost | Generally average product particle shape, high content of needle-like and flaky particles; relatively high vibration and noise | Primary crushing (first crusher), coarse crushing operations in mines |

| Cone Crusher | Layered Crushing | Medium to high hardness materials, especially those requiring fine aggregate particle shape | High production efficiency, long wear part life, stable operation, excellent product particle shape, high degree of automation | Higher initial investment cost; complex structure, high maintenance technical requirements | Secondary or tertiary medium and fine crushing, core of high-quality aggregate production lines |

| Impact Crusher | Impact Crushing | Medium to low hardness, low abrasiveness materials (e.g., limestone, sandstone) | Large crushing ratio, good product particle shape, convenient adjustment of discharge particle size, relatively light equipment weight | Impact parts wear out quickly, making it uneconomical for processing high-hardness materials; dust generation may be significant. | Medium to fine crushing, especially suitable for producing construction stone and limestone. |

| Mobile Crushing Plant | Integrates multiple crushers from the above into a mobile chassis. | Widely used for construction waste processing, small to medium-sized mines, demolition sites, etc. | Extremely flexible, can be moved according to changes in raw material location, allowing for rapid deployment and reduced material transportation costs. | High unit price; limited by vehicle size, the processing capacity of a single unit is usually lower than that of a fixed unit of the same model. | Suitable for urban construction waste resource recovery and various engineering projects requiring relocation. |

III. The Deeper Logic of Choosing the "Best" Equipment

Parameter tables are fundamental, but the definition of "best" equipment varies from person to person. As a marketing expert, I must point out that the truly "best" is the equipment that creates the greatest long-term value for you. This includes:

1. Life Cycle Cost (LCC): Not only should you look at the purchase price, but you should also estimate energy consumption, wear parts consumption, maintenance downtime, and labor costs over 5-10 years. 1. A slightly higher initial price but superior efficiency and durability: This type of equipment often has a lower total cost of ownership.

2. Production System Compatibility: A crusher is not an island. It needs to work seamlessly with feeders, vibrating screens, conveyors, and even dust collection systems. When selecting a crusher, its compatibility and efficiency contribution throughout the entire process must be considered.

3. Technical Reserves and Service Response: Does the supplier possess deep technical expertise? Can they provide customized solutions? Is their after-sales service network sound? Are spare parts supplied promptly? These "soft power" qualities are the "insurance policy" for the long-term stable operation of the equipment.

4. Intelligent and Environmentally Friendly Empowerment: Modern high-end crushing equipment integrates intelligent monitoring, remote operation and maintenance, and automatic adjustment systems, significantly improving management efficiency and safety. Simultaneously, compliance with increasingly stringent environmental standards is a prerequisite for sustainable enterprise development.

Choosing stone crushing equipment is a decision that combines engineering technology, economics, and strategic vision. There is no single answer, but there are scientific methods. We are not only equipment providers but also your partner in upgrading productivity. We are committed to helping you precisely match the "best" equipment that can "break" cost bottlenecks and "create" higher profits through our professional product line and comprehensive solutions, refining true gold from the ore of the market.