Magnetic Separation Equipment for Dry Powders

As a professional manufacturer with 20 years of experience in the mineral processing equipment field, we deeply understand the core role of dry magnetic separators in mineral processing. Achieving efficient separation of magnetic minerals without the need for water not only saves water resources but also reduces subsequent processing costs. This article will provide an in-depth analysis of the working principle, key technical parameters, application scenarios, and selection guidelines for dry magnetic separators, offering professional reference for your project.

I. Working Principle and Core Advantages of Dry Magnetic Separators

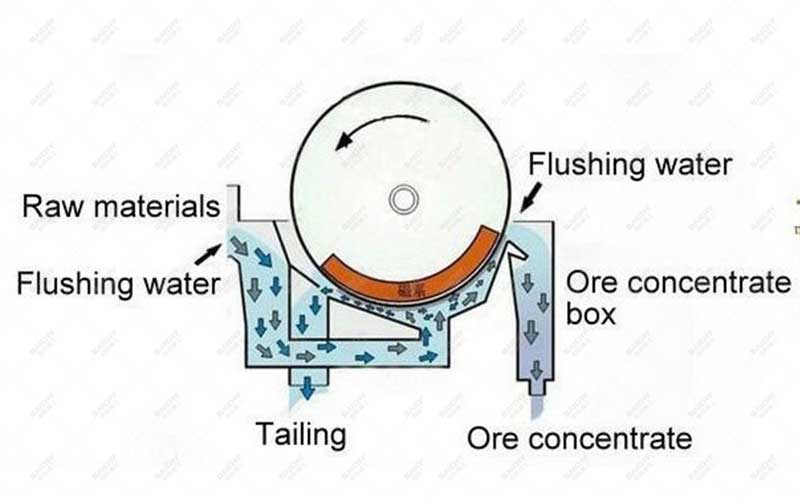

Dry magnetic separatorsprimarily utilize the magnetic differences between minerals, achieving separation through magnetic force in a dry state. Its core lies in the magnetic system design, typically employing high-performance permanent magnet materials (such as neodymium iron boron) or electromagnetic coils to generate a high-intensity magnetic field.

Core advantages include:

Environmentally friendly and energy-saving: Requires no water, making it particularly suitable for arid and water-scarce areas or projects where wastewater discharge is prohibited.

Simplified process: Eliminates wet processes such as concentration, filtration, and drying, resulting in lower investment and operating costs.

High Adaptability: Capable of handling powdery and granular materials with low moisture content (typically <5%).

High Sorting Efficiency: For strongly magnetic minerals (such as magnetite), recovery rates can reach over 99%.

II. Key Technologies and Performance Parameters Explained

The performance of the equipment is determined by multiple technical parameters. Understanding these parameters is the foundation for correct equipment selection.

Table 1: Comparison of Main Types and Characteristics of Dry Powder Magnetic Separation Equipment

| Equipment Type | Magnetic Field Strength Range (Gauss) | Applicable Mineral Magnetic Properties | Processing Particle Size Range (mm) | Typical Applications |

| Dry Drum Magnetic Separator | 1000 - 6000 | Strongly Magnetic Minerals | 0.1 - 20 | Magnetite Primary Concentration and Tailings Disposal |

| Dry Roller Magnetic Separator | 6000 - 15000 | Medium to Weakly Magnetic Minerals | 0.05 - 3 | Ilmenite, Chromite, and Manganese Ore Separation |

| Dry Disc Magnetic Separator | 10000 - 20000+ | Weakly Magnetic Minerals | 0.05 - 2 | Feldspar, Quartz, and Andalusite Purification |

| Suspension Magnetic Separator | 5000 - 12000 | Strongly Magnetic Minerals | 0.074 - 6 | Automatic Iron Removal from Crushed Material |

Table 2: Key Operating Parameters Affecting Separation Effect

| Parameter Name | Impact Description | Adjustment Suggestions |

| Feed Particle Size | Too coarse, incomplete separation; too fine, dust generation | Ensure material is within the equipment's optimal processing range |

| Feed Speed | Too fast, insufficient separation | Optimize according to processing capacity and concentrate grade requirements |

| Magnetic Field Strength | Directly affects magnetic force | Select and adjust according to mineral specific magnetization coefficient |

| Separation Gap | Affects magnetic field gradient and depth of action | Precisely adjust according to particle size and processing capacity |

III. How to Choose the Right Equipment Based on Your Mineral Characteristics?

Twenty years of experience tell us that there is no "one-size-fits-all" equipment, only the "most suitable" solution. Equipment selection must be based on detailed mineralogical analysis.

1. Mineral Magnetic Analysis: The primary task is to determine the specific magnetic susceptibility of the mineral. This is the fundamental basis for distinguishing between strongly magnetic, moderately magnetic, weakly magnetic, and non-magnetic minerals.

2. Particle Size Analysis: Perform sieving analysis on the raw materials to ensure that their particle size is within the ideal processing window of the target equipment.

3. Processing Capacity Requirements: Determine the hourly or annual processing capacity, which determines the equipment specifications and model.

4. Sorting Objectives: Is the primary focus on high recovery rate or high concentrate grade? Different objectives require different equipment and process configuration strategies.

5. Site Conditions: Consider practical factors such as installation space, power supply, altitude, and ambient temperature.

IV. Our Professional Value: Twenty Years of Experience

With twenty years of technical expertise and experience in hundreds of projects, we can provide you with:

Precise Laboratory Sorting Tests: Provide reliable predictive data before equipment selection.

Customized Design: Optimize equipment structure and magnetic circuit based on your mineral characteristics and plant layout.

Wear-Resistant Protection Solution: Apply wear-resistant materials such as ceramics and polyurethane to key abrasion points, significantly extending equipment life.

Intelligent Control System: Integrated PLC control enables automated adjustment of feed speed and magnetic roller speed, ensuring separation stability.

Dry powder magnetic separation technology is a powerful tool for achieving efficient and environmentally friendly mineral separation. Choosing the right equipment is a crucial step in achieving both economic and environmental benefits. We sincerely invite you to bring your mineral samples, and let us leverage our twenty years of professional experience to provide you with a comprehensive solution from experimental analysis and solution design to equipment delivery.