Magnetic Separation Equipment

In complex mineral processing procedures, efficiently and accurately separating target components from mineral mixtures is crucial to production efficiency and product quality. Magnetic separation technology, with its significant advantages of physical separation, environmental friendliness, and low operating costs, has become an indispensable core component of the modern mineral processing industry. A high-performance, highly stable magnetic separatoris the heart of this process. As a mineral processing equipment manufacturer with twenty years of focused experience, we deeply understand the characteristics of each ore and the pursuit of efficiency and reliability by every customer.

Magnetic Separation Technology Principles and Main Equipment Types

Magnetic separation is a method of separating minerals based on differences in magnetic properties within a non-uniform magnetic field. Based on the different magnetic field strengths, magnetic separation equipment is mainly pided into the following categories:

| Equipment Type | Magnetic Field Strength Range | Main Applicable Minerals | Process Characteristics |

| Weak Magnetic Field Separator | < 0.2 T | Strongly Magnetic Minerals (Magnetite, Ti:magnetite, etc.) | Magnetic system is mostly permanent magnets; simple structure; large processing capacity. |

| Medium Magnetic Field Separator | 0.2 - 0.8 T | Medium magnetic minerals (some ilmenite, chromite, etc.) | Commonly used as roughing or scavenging equipment, with high recovery rates. |

| High Magnetic Field Separator | 0.8 - 2.0 T | Weakly magnetic minerals (hematite, limonite, manganese ore, etc.) | Complex magnetic system (electromagnetic or strong permanent magnet), requiring high separation accuracy. |

| High Gradient Magnetic Separator | > 2.0 T | Extremely weakly magnetic minerals or fine-grained minerals | High background field strength, the magnetic medium generates an extremely high gradient, used for fine separation. |

Twenty years of R&D and field practice allow us to provide the most suitable equipment solutions for different mineral magnetic characteristics and process stages.

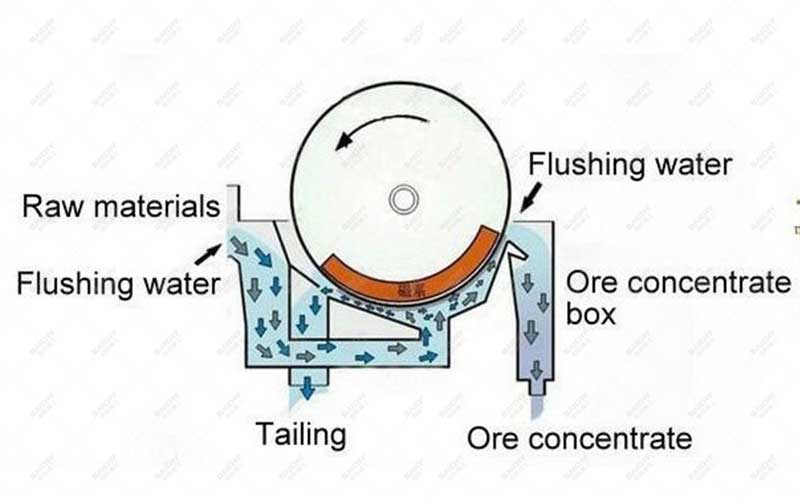

Magnetic separator structure diagram

Our Core Advantage: Twenty Years of Dedication and Innovation

Through long-term technological accumulation, we have built core competitiveness that transcends the equipment itself:

1. Deep Process Understanding: We are not only an equipment manufacturer, but also a solution partner for mineral processing. For two decades, we have processed hundreds of different ore samples, accumulating a vast database of mineral magnetic properties and process parameter models. We can provide you with initial advice, from mineral beneficiation testing to production line design.

2. Cutting-Edge Technological Innovation:

◦ Magnetic Circuit Optimization Design: Utilizing advanced computer simulation software, we optimize the magnetic system to ensure a more rational magnetic field distribution, a longer effective sorting zone, higher magnetic material recovery rate, and lower non-magnetic material inclusion rate.

◦ High-Efficiency Permanent Magnet Material Application: We fully utilize high-performance neodymium iron boron (NdFeB) permanent magnet materials, ensuring that the equipment's magnetic performance decays by less than 5% within ten years, significantly reducing operating energy consumption and eliminating the high electricity and cooling costs associated with electromagnetic equipment.

◦ Robust and Intelligent Structure: The main body of the equipment adopts a heavy-duty steel structure, and key components undergo finite element analysis to ensure stability under heavy loads and continuous operation. Simultaneously, temperature and vibration sensors can be integrated to achieve online monitoring and early warning of equipment operating status.

3. Full Lifecycle Service:

Our services cover the entire lifecycle of the equipment, ensuring maximum investment value for our clients.

| Service Stages | Service Content |

| Pre-sales | Free mineral testing, process flow design, small-scale pilot sorting. |

| During Sales | Customized equipment manufacturing, full-process testing before delivery, installation manual. |

| After-sales | On-site installation and commissioning guidance by professional engineers, operator training, global spare parts supply network, regular follow-up visits and preventative maintenance recommendations. |

Typical Application Scenarios and Success Stories

Our magnetic separation equipment has been widely used in many fields worldwide:

• Ferrous metal ores: Refinement and purification of magnetite, significantly improving iron concentrate grade.

• Non-ferrous metal ores: Iron removal from tungsten and tin ores, improving the purity of non-magnetic products.

• Waste resource recycling: Recovery of valuable metals from steel slag, grinding mill shavings, and electronic waste, turning waste into treasure.

• Non-metallic mineral purification: Iron removal and whitening of raw materials such as quartz, feldspar, and kaolin, increasing product added value.

Case Study: In 2020, we provided a complete high-intensity magnetic separation solution for a large-scale iron ore renovation project in Southeast Asia. By adopting our new high-gradient vertical ring magnetic separator, with a feed particle size of -200 mesh accounting for 75%, the final iron concentrate grade increased from the original 62% to 68.5%, while the tailings grade decreased by more than 2 percentage points, creating millions of dollars in additional benefits for customers annually.

How to Choose the Right Magnetic Separation Equipment for You?

Choosing the right equipment is a systematic project. We recommend considering the following dimensions comprehensively:

1. Mineral Properties: This is fundamental. The specific magnetic susceptibility, particle size distribution, and intergrowth characteristics of the minerals must be determined experimentally.

2. Production Objectives: Clearly define the required concentrate grade, recovery rate, throughput, and other core indicators.

3. Process Flow Positioning: Is the equipment used for roughing, cleaning, or scavenging? What are the upstream and downstream processes?

4. Investment and Operating Costs: Weigh the one-time equipment investment against long-term electricity, maintenance, and spare parts consumption costs.

The best advice is: Contact us with your ore samples. Our technical team will simulate the sorting process for you in the laboratory, using real data to outline the optimal solution.

Facing the global trend of green and intelligent development in the mining industry, we continuously invest in research and development:

• Zero-pollution process: Magnetic separation, as a purely physical sorting method, is inherently environmentally friendly. We are committed to further reducing equipment noise and operating energy consumption.

• Intelligent control: We have developed an automatic control system based on AI algorithms that can adjust equipment parameters (such as rotation speed and excitation current) in real time according to changes in feed properties, achieving adaptive stable production.

• Modular design: This makes equipment installation, relocation, and expansion faster, adapting to more perse production scenarios.

Twenty years of focus have yielded not only technology but also a commitment to customer success. Choosing us means you get not only a high-quality magnetic separator but also a trustworthy long-term process partner. Let us use the power of magnetism to provide the core driving force for enhancing the value of your resources.