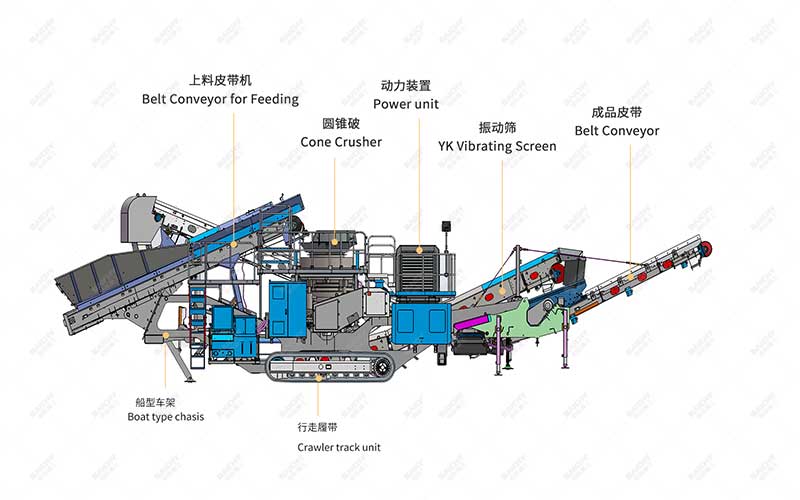

Crawler-Type Mobile Cone Crusher

Two decades of dedicated focus on crushing as a manufacturer of mining crushing equipment with two decades of deep industry experience, we have witnessed every technological leap from fixed production lines to mobile crushing plants. Today, we will provide you with an in-depth analysis of the flexible trump card in the mining crushing field the tracked mobile crusher.

Crawler Crusher PDF,Download ↓↓↓

Why has the tracked mobile crusher become the mainstream in the market?

In traditional sand and gravel aggregate production and construction waste processing projects, fixed crushing production lines require complex infrastructure, long installation cycles, and high transportation costs. The emergence of the tracked mobile crusher has completely revolutionized this model.

It integrates feeding, crushing, screening, and conveying, and adopts a fully tracked chassis, enabling the entire equipment to move and turn on the spot. This design allows it to go directly to the raw material location or work surface, achieving crushing wherever the raw material is, greatly reducing material transportation costs, and is particularly suitable for working conditions with complex terrain and dispersed work sites.

Key Advantages at a Glance

| Advantages and Features | Detailed Description |

| High Mobility and Flexibility | Tracked movement prevents road damage; remotely controlled operation adapts to complex terrains such as mountains and wetlands. |

| Rapid Deployment, Immediate Operation | No piling required; simply connect power upon arrival to quickly begin production, saving significant preparation time. |

| Integrated Design, Cost Savings | Each machine forms its own production line, reducing connection costs and site occupancy between equipment, resulting in a shorter return on investment cycle. |

| Multiple Configurations, Wide Applications | Can be equipped with jaw crushers, impact crushers, cone crushers, screening machines, etc., meeting various needs such as coarse, medium, and fine crushing, and screening. |

| Environmentally Friendly and Energy-Saving | Noise Reduction and Dust Control | Modern models emphasize environmentally friendly design, equipped with spray systems and sealed structures to effectively control dust and noise pollution. |

| Intelligent Control, Easy Operation | Utilizes a PLC intelligent control system with one-button start/stop, self-diagnosis of faults, minimal operator requirements, and a high safety factor. |

Unveiling the Core: How Does a Tracked Mobile Crushing Plant Work?

A complete tracked mobile crusher is a sophisticated, coordinated system. Its workflow can be summarized in the following stages:

Tracked mobile cone crusher structural diagram

1. Feeding: Raw materials are fed evenly and continuously into the crusher main unit via a vibrating feeder.

2. Crushing: The core stage. The raw materials are crushed within the crushing chamber through compression, impact, and grinding.

3. Screening: The crushed material is conveyed to a vibrating screen via a belt conveyor, separating it into finished products of different specifications. Qualified finished products are output, while unqualified materials are returned to the crusher or enter the next stage of crushing (in multi-machine combined operation).

4. Mobility and Power: Mobility is provided by a robust tracked chassis. Power sources can be selected from a diesel engine or external mains power, ensuring normal operation even in mountainous areas without electricity.

How to Choose the Right Model for You? 20 Years of Experience Selection Guide

When choosing a tracked mobile crusher, price should not be the sole consideration; a comprehensive matching of operating conditions is essential. Below is a selection consideration table summarized based on our 20 years of customer service experience:

| Consideration Dimensions | Key Issues and Selection Recommendations |

| Raw Material Properties | What are the material's hardness (Mohs hardness), particle size, moisture content, and mud content? For high-hardness materials (such as granite), a cone crusher is recommended; for medium-to-low hardness materials (such as limestone), an impact crusher is preferable. |

| Output Requirements | What is the expected hourly or daily output? This is the core parameter determining the machine size. |

| Finished Product Requirements | How many finished product specifications are required? What are the requirements for particle shape and gradation? This determines whether a multi-layer screen and shaping machine are needed. |

| Working Conditions and Terrain | Is the work site flat? What is the slope? Tracked machines are most adaptable to complex terrain. |

| Power Source | Is there a stable power supply at the work site? For areas without electricity or in remote areas, diesel engine-driven versions should be preferred. |

| Long-Term Planning | Is the work location fixed and long-term or frequently relocated? With high relocation frequency, the flexibility of mobile stations becomes increasingly apparent. |

| Environmental Requirements | What are the noise and dust emission standards at the project site? A model equipped with appropriate environmental protection devices must be selected. |

Main Application Scenarios: Beyond Mining

The application of tracked mobile crushers extends far beyond traditional mining:

• Construction Waste Recycling: On-site crushing at urban demolition sites to generate recycled aggregates, a key piece of equipment for zero-waste city construction.

• Highway and Railway Construction: In road construction, stone processing can be carried out directly at mountain tunnel entrances or near roadbeds, reducing transportation distances.

• Sand and Gravel Aggregate Production: In river sand mining or mountain quarrying, it can move with the advance of the mining face, offering flexibility and efficiency.

• Disaster Area Construction Waste Treatment: Quickly enters the site to treat post-earthquake and disaster-stricken building debris.

As a specialist in the mining crushing field for twenty years, we deeply understand that every construction site presents its unique challenges. Tracked mobile crushers represent not just a piece of equipment, but a modern production concept that is efficient, flexible, and low-carbon. By mobilizing the production line, it brings users unprecedented operational freedom and cost control capabilities.

If you are facing challenges such as high material handling costs, numerous site restrictions, and stringent environmental requirements, a tracked mobile crusher may be your optimal solution. Welcome to contact us; with our twenty years of technical expertise and extensive project experience, we can provide you with the most professional equipment selection and solutions.