Double Roller Crusher

In Ethiopia's booming infrastructure development, the demand for high-quality, low-cost manufactured sand is increasing. We have noticed that many Ethiopian customers, when making inquiries, are particularly interested in double-roll crushers for sand production. This is not a coincidence, but rather based on a comprehensive consideration of equipment adaptability, output particle size, and return on investment in the local market. Compared to impact crushers, double-roll crushers often demonstrate unique advantages when processing materials of medium hardness or less (such as limestone and marl, which are common in Ethiopia).

| Key Words | Sand Production Solutions |

|---|---|

| Product Model | Double Roller Crusher |

| Feed Size | ≤110mm |

| Motor Power | 11-90kw |

| Capacity | 10-85t/h |

| Core Advantages | Slow-speed crushing method |

| Brand | Baichy Heavy Industry |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

What is double-roll crusher sand production?

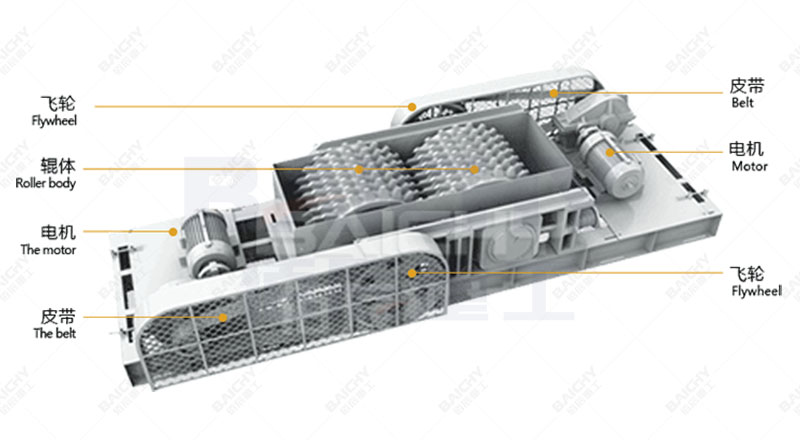

A double-roll crusher, as the name suggests, crushes materials by squeezing and shearing them between two counter-rotating rollers. When used in sand production, the gap between the two rollers is precisely controlled to adjust the output particle size. The smaller the gap, the finer the output, and after screening, the required manufactured sand can be obtained. The sand produced by this method has a uniform particle size, good particle shape (cubic or polyhedral), and controllable powder content, making it ideal for concrete preparation and building construction.

Structural diagram of a double-toothed roller crusher

Core Advantages of Double-Roll Crushers for Sand Production

As a mining crushing equipment manufacturer with 20 years of experience, we deeply understand our customers' pain points. The following are the outstanding advantages of double-roll crushers in sand production applications:

1. Flexible and controllable output particle size: The roller gap is easy to adjust, allowing for the production of 0-5mm fine sand or coarser aggregates according to market demand, enabling multi-purpose use and meeting perse production needs.

2. Low over-crushing rate and excellent particle shape: Primarily using compression crushing, it produces relatively less stone powder compared to impact crushers. The finished sand particles have sharp edges and corners, and a reasonable gradation, effectively improving concrete strength.

3. Simple structure and convenient maintenance: The mechanical structure is robust and reliable, and core components such as the roller shells are made of high-wear-resistant alloy materials, resulting in a long service life. Daily maintenance costs are far lower than those of complex equipment, making it particularly suitable for operation and maintenance in Ethiopia.

4. Stronger adaptability to wet materials: For materials with slightly higher moisture content, the risk of clogging in double-roll crushers is far lower than that of impact crushers or cone crushers, ensuring the continuous and stable operation of the production line. 5. High Investment and Operating Cost-Effectiveness: Reasonable initial investment and relatively low energy consumption make it a highly cost-effective option for small and medium-sized sand plants or for in-house sand production projects.

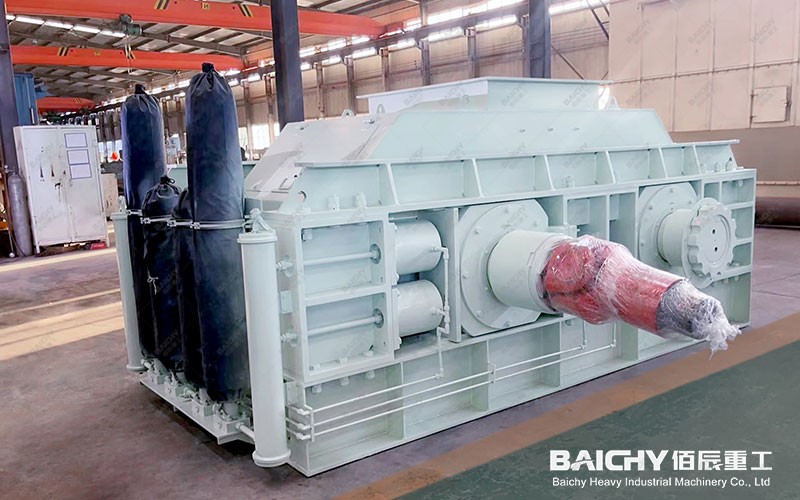

Double-toothed roller crusher at a customer's site.

Success Stories: Our Equipment in Similar Markets

We have provided double-roll sand making solutions to customers in several East African countries. For example, we configured a small to medium-sized sand production line centered around a double-roll crusher for a limestone quarry in Kenya. This production line produces 50 tons of high-quality manufactured sand per hour, with the finished product mainly used in local residential construction. The customer reported that our equipment operates stably, and the roller shell wear cycle lasts for more than 6 months, significantly reducing their production costs. The output particle size fully meets Kenyan national standards, securing them continuous orders.

Related Equipment Recommendations

An efficient sand production line is more than just a double-roll crusher. As your comprehensive partner, we can provide a complete solution:

• Feeding Equipment: Vibrating feeder, ensuring uniform and continuous feeding.

• Pre-processing Equipment: Jaw crusher, for primary crushing of large raw materials.

• Screening Equipment: Vibrating screen, to classify the crushed materials and separate qualified finished products.

• Conveying Equipment: Belt conveyor, connecting each process stage.

We can provide professional design and support, from single machines to complete production lines, based on your specific raw materials, capacity requirements, and site conditions.

FAQ

Q: Can the double-roll crusher handle granite or basalt?

A: Yes, it can, but for high-hardness materials, roller shell wear will accelerate. We recommend equipping it with specially designed ultra-high wear-resistant roller shells and evaluating the economics based on actual conditions. For high-hardness sand production, we also recommend a combination of jaw crusher + cone crusher + impact crusher.

Q: What is the footprint of a 100-ton per hour sand production line?

A: A compact production line including feeding, primary crushing, double-roll sand making, and screening will occupy an area of approximately 20m x 30m. We can provide detailed site layout drawings.

Q: Do you provide installation guidance and after-sales service?

A: Yes, this is one of our core strengths. We provide detailed installation drawings, process flow charts, and remote video guidance. We offer a 12-month warranty and maintain a stock of spare parts to ensure a quick response. Our engineers can also provide paid on-site installation and commissioning services.

Q: How to control the fines content in the finished sand?

A: There are two main methods: First, install screening equipment after the double-roll crusher to remove excessively fine stone powder; second, equip the end of the production line with a dust collector or classifier. This allows for more precise control of the stone powder content, meeting the requirements for high-standard concrete sand.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.