Gold Dressing Equipment and Sorting Machine Overview

Why is gold beneficiation a core technology?

Gold, this precious metal, does not exist in nature primarily as visible "gold nuggets." It typically exists as extremely fine particles embedded in ore, in very low concentrations. Therefore, gold beneficiation is a crucial technological link in the entire gold mining process. Its purpose is to efficiently and economically separate and concentrate gold from the ore, providing qualified raw materials for subsequent smelting and refining. The sophistication of beneficiation processes and equipment directly determines the gold recovery rate, production costs, and resource utilization rate.

| Key Words | Gold Dressing Equipment and Sorting Machine Overview |

|---|---|

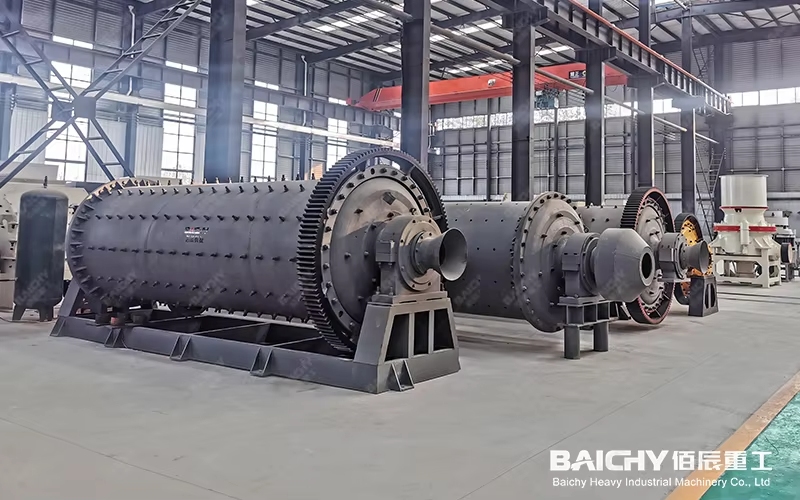

| Product Model | Ball Mill |

| Feed Size | ≤25mm |

| Motor Power | 18.5-4500kw |

| Capacity | 0.65-615t/h |

| Core Functions | Grinding precision and particle size controllability |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Overview of Gold Beneficiation Equipment and Separators

Gold beneficiation is a multi-stage, multi-process collaborative process that requires a series of specialized equipment to form a production line. The process flow varies depending on the ore properties (e.g., placer gold, vein gold, oxide ore, sulfide ore, etc.), but the main stages and core equipment are summarized below:

Detailed Explanation of Core Separation Equipment

1. Jaw Crusher & Cone Crusher: As the core of coarse and medium crushing, they are responsible for crushing large pieces of raw ore to a suitable grinding size. Their robustness and durability are the foundation for the continuous and stable operation of the production line.

2. Ball Mill/Rod Mill: Key equipment in the grinding stage, further refining the crushed ore to fully "liberate" the gold minerals, creating the necessary conditions for separation.

3. Jig: Commonly used to process coarse-grained gold or placer gold ores, utilizing water pulsation to stratify light and heavy minerals, achieving gravity separation.

4. Shaking Table: Utilizing mechanical shaking and water washing, it separates minerals according to particle density and size, showing significant effectiveness in recovering fine-grained gold; it is a classic gravity separation device.

5. Flotation Machine (One of the Core Separators): Crucial for processing finely disseminated sulfide gold ores. By adding reagents, gold minerals selectively adhere to bubbles and float, achieving efficient separation from gangue.

6. Centrifugal Concentrator/Nelson Concentrator: Utilizing a powerful centrifugal force field, this greatly enhances gravity separation, efficiently recovering fine gold particles, especially free gold.

7. Carbon-In-Pulp Adsorption/Leaching Tank: For refractory gold ores using cyanidation or environmentally friendly leaching agents, this equipment is used for gold leaching and adsorption.

Ball mill mineral processing flow chart

Our Equipment and Technology Advantages

With 20 years of experience, we are not only an equipment manufacturer but also a solutions provider. Our advantages include:

• High Efficiency and High Recovery Rate: Scientifically designed equipment optimized for the physicochemical properties of gold minerals, ensuring the highest gold recovery rate and reducing resource waste.

• Stability and Durability: Utilizing high-quality materials and heavy-duty design, the equipment ensures long-term, continuous, and stable operation under harsh conditions, reducing failure rates and maintenance costs.

• Energy Saving and Environmental Protection: Optimizing the equipment's power system reduces energy consumption; providing environmentally friendly mineral processing solutions (such as cyanide-free leaching equipment) helps customers fulfill their social responsibilities.

• Customized Solutions: We offer free mineral testing and process design, tailoring solutions from single equipment to complete production lines based on your ore analysis reports (such as spectral analysis and microscopic identification).

Success Story: A 500 TPD Gold Mine Beneficiation Plant Project in Central Asia

We built a beneficiation plant for a Central Asian client with a daily processing capacity of 500 tons of gold ore. The raw ore was a gold-bearing quartz vein sulfide ore with uneven gold particle size distribution.

• Challenge: High proportion of fine-grained gold; traditional single gravity separation yielded unsatisfactory recovery rates.

• Solution: We designed a combined gravity separation + flotation process. The process employs a two-stage crushing method using a jaw crusher and a cone crusher, followed by closed-circuit grinding with a ball mill. First, a Nelson centrifugal concentrator recovers the liberated coarse and medium-grained free gold. Then, a flotation machine enriches the fine-grained gold and gold from sulfide minerals.

• Results: The total gold recovery rate increased from the customer's expected 85% to 92.5%. Furthermore, the pre-gravity separation process significantly reduced flotation reagent costs and subsequent processing volume, resulting in a significantly shorter payback period.

Recommended Related Equipment

If you are planning or upgrading a gold mine beneficiation project, the following are our market-proven star product series:

• High-Efficiency Jaw Crusher: High crushing ratio, low energy consumption.

• Ball Mill: Designed specifically for full liberation of gold ore, with long liner life.

• Aerated Mechanical Agitator Flotation Machine: Large air intake, low energy consumption, suitable for flotation of precious metals such as gold and silver.

• Centrifugal Concentrator: Enhanced gravity separation, with excellent recovery of fine gold particles.

Frequently Asked Questions (FAQ)

Q1: How do I determine the optimal beneficiation process and equipment for my gold mine?

A: The most crucial step is conducting detailed ore beneficiation tests. Please send us representative ore samples. Our laboratory will conduct chemical analysis, rock and mineral identification, and continuous beneficiation tests to recommend the most economical and efficient "tailor-made" process and equipment configuration for you.

Q2: Can your equipment handle oxidized gold ore with high clay content?

A: Yes. For viscous oxidized ores, we usually recommend adding a washing or scrubbing process after crushing, using specialized washing or scrubbing machines to disperse the slime, prevent equipment blockage, and ensure the efficiency of subsequent gravity separation or leaching processes.

Q3: How does your equipment compare to competitors in terms of after-sales maintenance and spare parts supply?

A: We offer a global spare parts supply network, with critical spare parts in stock year-round. The equipment features a modular design for easy maintenance. We provide detailed maintenance manuals, online video tutorials, and remote technical support to ensure minimal downtime for your production l

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.

ine.