Namibia Hard Rock Gold Mine Beneficiation Scheme

This is a very specific and valuable project requirement. Let's conduct a systematic, multi-layered in-depth analysis of the customer's needs for this "300 tons/day hard rock gold mine processing plant" in Namibia.

Core Needs Positioning

The customer's core demand is to find a "solution," not just to purchase equipment. This suggests the project is likely in the feasibility study, preliminary design, or bidding stage. The customer is likely a mine owner, investor, or EPC contractor, and they need a complete, cost-effective, reliable, and compliant technical package and implementation plan from ore to finished product.

Needs Hierarchy Analysis

First Level: Explicit Technical and Performance Requirements (directly stated by the customer)

1. Processing Capacity: 300 tons/day (approximately 12.5 tons/hour). This is a small to medium-sized processing plant; the solution needs to emphasize modularity, compactness, and cost-effectiveness, rather than large-scale, fully automated systems.

2. Ore Properties: Hard rock gold ore. This is crucial information that directly determines the process route.

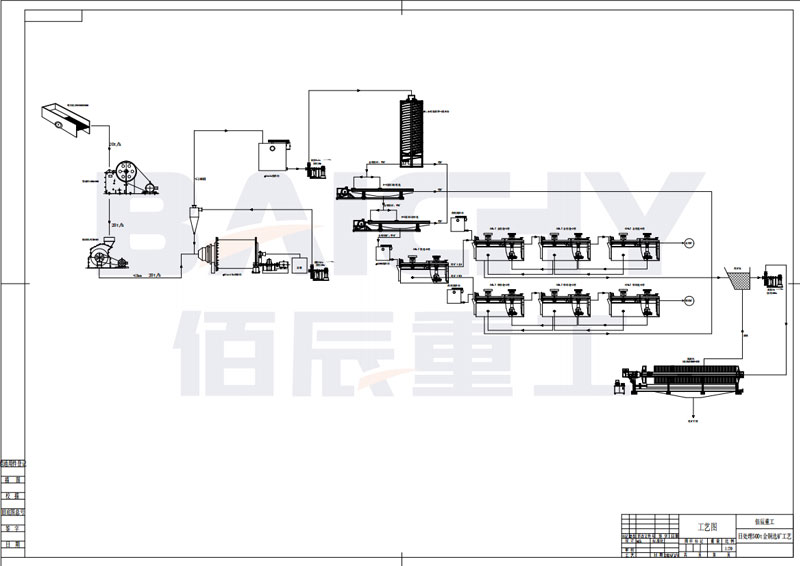

◦ Crushing: Requires at least two stages (coarse crushing + fine crushing), possibly three stages to meet the feed requirements. Equipment must be wear-resistant and impact-resistant.

◦ Grinding: High energy consumption. Requires an efficient and energy-saving ball mill/semi-autogenous grinding solution, and consideration of handling hard rocks.

◦ Gold Occurrence: May be quartz vein type, sulfide ore (such as associated with pyrite, arsenopyrite), or associated gold. This determines the separation process:

▪ If it is coarse-grained free gold: Gravity separation (such as Nelson centrifugal concentrator, shaking table) may be needed for early recovery to reduce costs.

▪ If it is fine-grained encapsulated gold: Flotation or chemical leaching (whole-ore cyanidation/flotation concentrate cyanidation) must be used.

3. Final Product: Usually gold bullion or high-grade gold concentrate. The product form determines whether the end of the process is a refining plant or direct concentrate sales.

Second Level: Implicit Commercial and Operational Needs (core interests of the customer)

1. Investment Cost Control: Small and medium-sized projects are extremely sensitive to CAPEX (capital expenditure). The solution must, while meeting process requirements, strive to simplify the process, select cost-effective equipment, and provide flexible financing or payment options.

2. Operational Cost Optimization: The focus is on reducing electricity consumption, steel consumption (grinding media and wear parts), and reagent consumption. The proposal must provide a detailed OPEX (operating cost) analysis, especially regarding recovery rate; every 1% increase can bring significant economic benefits.

3. Rapid Commissioning and Return on Investment: The client wants a short construction period to generate cash flow as quickly as possible. Modular and prefabricated plant design is a huge advantage, reducing on-site construction time and costs.

4. Process Reliability and Adaptability: The process must be mature and reliable, and adaptable to possible fluctuations in ore properties. Pilot plant or similar project data should be provided as support.

5. Localization and Sustainability:

◦ Environmental Compliance: Namibia has strict environmental requirements. The solution must include environmental protection measures such as tailings treatment (dry/wet stacking), wastewater recycling, and cyanide management (if used).

◦ Community and Policy: Considering the skill level of the local workforce, the solution should be easy to operate and maintain, and provide training. Understanding the country's mining policies and foreign investment requirements will also help build trust.

Third Level: Deeper Strategic and Risk Mitigation Needs (Considerations for Decision-Makers)

1. Capabilities of a Comprehensive Solution Provider:

The client is not looking for an "equipment vendor," but a partner who can provide "one-stop service." This includes:

◦ Testing and Design: Ore amenability testing, process flow design, plant layout.

◦ Equipment Supply and Integration: Providing core and supporting equipment and ensuring their synergy.

◦ Construction and Commissioning: Installation guidance, commissioning, and achieving production targets.

◦ Operational Support: Long-term technical support, spare parts supply, and optimization services.

2. Balance between Technological Advancement and Practicality:

The solution should not be overly advanced (increasing costs and risks), but should adopt proven and applicable technologies that improve efficiency and reduce consumption (such as high-efficiency energy-saving motors and automation control).

3. Risk Sharing: The client expects the supplier to make reasonable commitments or guarantees on key performance indicators (such as recovery rate, throughput, and energy consumption), demonstrating confidence in their solution.

4. Long-Term Relationship and Commitment to Cooperation: Can the supplier provide a local agent or service network? Do they have successful cases in Southern Africa (especially Namibia)? This will greatly reduce the client's perceived risk. Key Recommendations for Solution Providers

Based on the above analysis, the following points should be emphasized when presenting solutions to Namibian clients:

1. Approach with a "Turnkey Project" or "Core Process Package" model: Demonstrate full-process capabilities, from ore testing and engineering design to equipment supply, commissioning, and operation.

2. Provide customized process flow diagrams: For "hard rock gold mines," present 2-3 comparative options (e.g., "Crushing-Grinding-Gravity Separation-Cyanidation" vs. "Crushing-Grinding-Flotation-Concentrate Processing"), including comparisons of investment, recovery rate, and costs for each option, demonstrating professionalism and a customer-centric approach.

3. Highlight the economic design of small and medium-sized projects:

Showcase compact 3D layouts to save land and infrastructure costs.

Recommend wear-resistant and energy-efficient equipment, and calculate their life cycle costs.

Emphasize modular design to shorten construction periods.

4. Address environmental concerns:

Provide detailed descriptions of tailings dry stacking, zero-discharge, or water resource recycling solutions.

If cyanidation is involved, explain safety management and detoxification measures.

5. Showcase localization and successful case studies:

Present similar project achievements in Africa, particularly in Namibia or neighboring countries (such as South Africa, Botswana, and Ghana).

Introduce available local services, training, and technical support systems.

6. Present a clear business model: In addition to the quotation, provide a clear financial analysis, demonstrating the project's return on investment, allowing clients to see a clear profit outlook.

Namibian clients are looking for more than just a technical blueprint for a mineral processing plant; they are seeking a strategic partner who can reduce investment risks, ensure long-term profitability, comply with local regulations, and establish a reliable cooperative relationship. A successful solution should deeply integrate technical feasibility with economic viability, environmental compliance with operational reliability, and win the client's final approval with clear data and successful localized case studies.

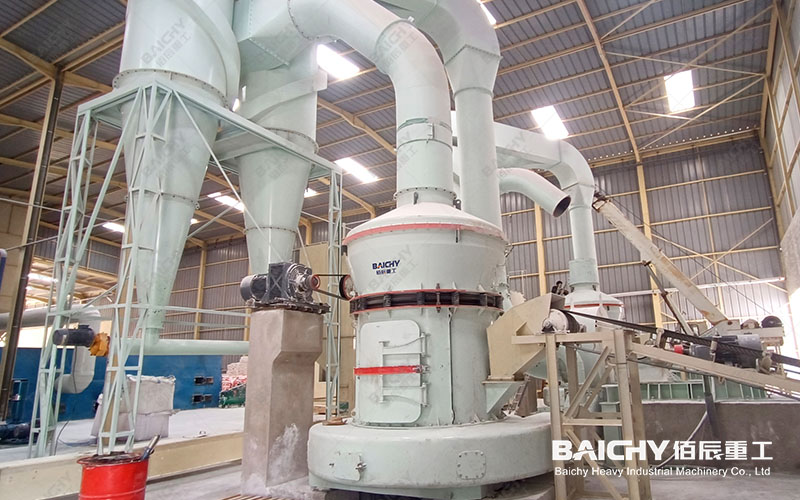

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!