Spiral Chute | Spiral Separator

Among the perse family of mineral processing equipment, there is a device renowned for its simple structure, reliable operation, and zero power consumption: the spiral chute, also often called a spiral separator. As a mineral processing equipment manufacturer with 20 years of experience, we understand that this seemingly simple device plays an irreplaceable and crucial role in specific mineral processing scenarios.

The spiral chute is essentially a mineral separation device based on the combined effects of gravity, centrifugal force, and water flow shear force. The mineral slurry is fed from the top and flows downwards along the spiral channel. During this process, mineral particles of different densities, sizes, and shapes are subjected to different combined forces, causing their trajectories to separate. This allows them to be collected at different positions at the bottom of the spiral chute, achieving effective separation of valuable minerals from gangue.

| Key Words | Spiral Chute | Spiral Separator |

|---|---|

| Product Model | Spiral Chutes |

| Feed Size | ≤0.02-0.3mm |

| Motor Power | -- |

| Capacity | 0.2-16t/h |

| Core Functions | Gravity is the fundamental driving force of the entire process. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

In-depth Analysis: Working Principle and Core Advantages of the Spiral Chute

Simple and Efficient Working Principle

The spiral chute's operation does not rely on any external power; its separation power comes entirely from the gravitational potential energy of the mineral slurry itself. As the slurry flows and rotates downwards along the spiral channel, the particles are mainly subjected to the following forces:

1. Gravity: Dominates the downward movement of the particles.

2. Centrifugal force: Pushes the particles towards the outer side of the chute.

3. Water flow shear force and friction force at the bottom of the chute: Affects the speed and direction of particle movement.

4. Bagnold force: The shear force exerted by the upper layer particles on the lower layer particles in the flow film, promoting stratification.

Under the combined action of these forces, denser, medium-sized particles (mostly heavy minerals) tend to move towards the inner side of the chute, while lighter minerals are carried to the outer side by the water flow, thus achieving gravity separation.

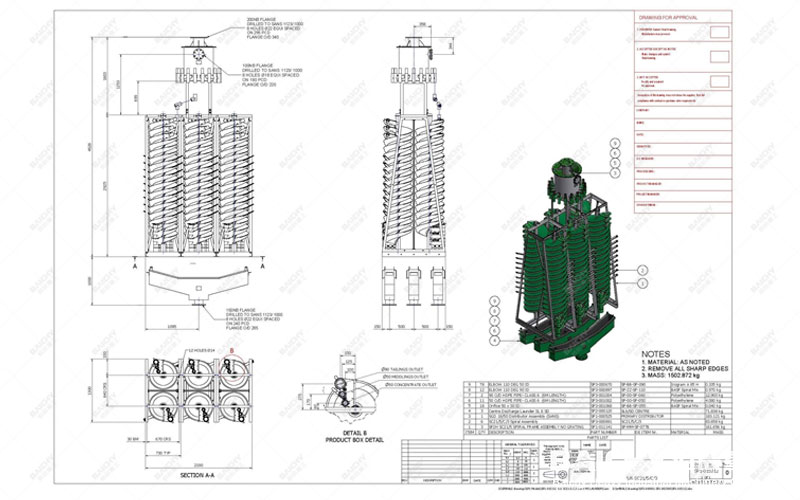

Spiral chute structure diagram

Unparalleled Outstanding Advantages

As an experienced mineral processing equipment manufacturer, we believe that the advantages of the spiral chute make it the preferred choice in many applications:

• Zero energy consumption, low cost: No motor drive is required, significantly reducing operating costs and energy consumption.

• Simple structure, easy maintenance: The equipment consists of a spiral chute body, feeder, and cutter, with almost no wear parts, resulting in extremely low failure rates and minimal maintenance. • High processing capacity and small footprint: A single unit can process a large amount of mineral slurry, and its vertical structure means it occupies a much smaller area than other equipment with the same processing capacity.

• Stable separation effect: As long as the ore properties and operating conditions are stable, the separation indicators are very reliable.

• Environmentally friendly and pollution-free: Pure physical wet separation, no chemical reagents are needed, making it environmentally friendly.

Application Cases: Successful Practices Demonstrate Value

In our 20 years of project experience, spiral chutes have excelled in various fields. For example, we provided a set of five-head cast iron spiral separators to a coastal sand mine project in Southeast Asia, used to separate light minerals such as quartz from ilmenite sand. Thanks to its excellent wear resistance and stable separation efficiency, the equipment operated continuously for over three years with almost no maintenance, helping the customer achieve preliminary ilmenite enrichment at a very low cost, resulting in a very high return on investment.

In another case, in the pre-concentration operation of a low-grade iron ore mine in China, we used spiral chutes to pre-remove a large amount of tailings, significantly reducing the load on the subsequent grinding and separation processes and significantly lowering the overall production cost. These cases demonstrate its unique value as an efficient and economical mineral processing equipment.

How to Choose and Combine? Related Equipment Recommendations

Although the spiral chute is powerful, it is not a panacea. It is mainly suitable for:

• Minerals with a particle size of 0.03-1mm (especially 0.1-0.037mm).

• Where there is a significant specific gravity difference between the valuable minerals and gangue.

• Situations requiring high processing capacity, moderate recovery rate, and low cost.

In actual mineral processing processes, spiral chutes are often used in conjunction with the following equipment:

• Feed preparation: It can be combined with vibrating screens for pre-screening, or with hydrocyclones for classification and desliming, creating optimal feed conditions for the spiral chute.

• Fine separation and scavenging: The rough concentrate from the spiral chute can be fed into a shaking table for fine separation to obtain high-grade concentrate; its tailings can be fed into a jig or other equipment for scavenging to improve the overall recovery rate.

• Dewatering Process: The separated concentrate and tailings can be sent to thickeners and dewatering screens for dewatering treatment.

Frequently Asked Questions (FAQ)

1. What are the differences between a spiral chute and a shaking table?

Both are gravity separation equipment, but their principles and applicable scenarios differ. Shaking tables rely on the reciprocating asymmetrical movement of the table surface for separation, handling finer particle sizes and achieving higher separation accuracy, but they have a smaller processing capacity per unit area and higher energy consumption. Spiral chutes, on the other hand, are completely non-powered, have a large processing capacity, and are low-cost, but their separation effect on very fine particles (-0.037mm) is usually not as precise as that of shaking tables. The two are often used in combination.

2. What are the main factors affecting the separation effect of a spiral chute?

Key factors include: feed concentration (needs to be stable within a suitable range), feed particle size distribution (too coarse or too fine will affect the result), feed rate (needs to be uniform and stable), the diameter, pitch, and cross-sectional shape of the spiral chute (designed for different ores), and the adjustment of the flushing water volume.

3. What wear-resistant treatment options do you offer for your spiral chutes?

Based on the abrasiveness of the customer's processed materials, we offer several options: wear-resistant polymer lining (such as polyurethane), special wear-resistant rubber lining, ceramic tiles, or integral cast iron/polymer materials. Our engineers will recommend the most cost-effective wear-resistant solution based on your ore characteristics (such as quartz content and particle angularity), which is a valuable accumulation of our 20 years of experience.