Gravity Conveyors | Spiral Chute

As a mining equipment manufacturer with 20 years of extensive experience, we deeply understand the fundamental role of the gravity conveyor | spiral chute combination in the field of mineral separation. It's not just a simple conveying tool, but a classic embodiment of wisdom that utilizes natural gravity to achieve efficient and economical mineral separation. This article will provide an in-depth analysis of the principles, advantages, and applications of the spiral chute, showcasing its enduring technological appeal.

| Key Words | Gravity Conveyors | Spiral Chute |

|---|---|

| Product Model | Spiral Chutes |

| Feed Size | ≤0.02-0.3mm |

| Motor Power | -- |

| Capacity | 0.2-16t/h |

| Core Functions | Gravity is the fundamental driving force of the entire process. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Spiral Chute: More Than Just Conveying, It's the Art of Efficient Separation

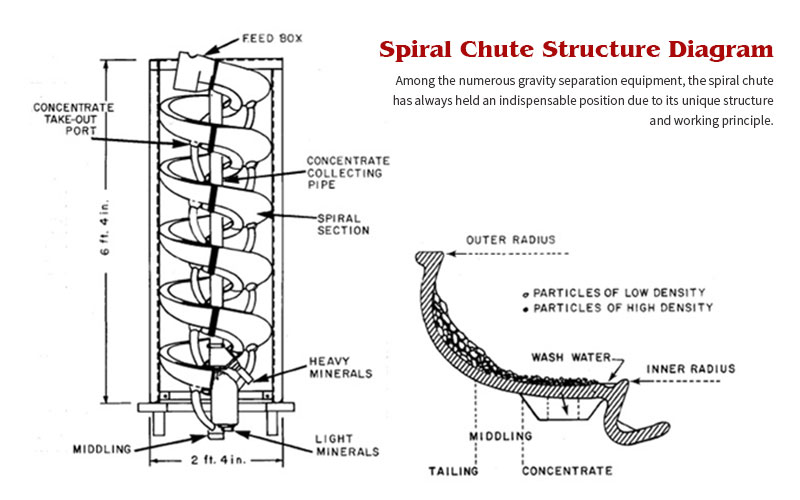

The spiral chute is often classified as a type of gravity conveyor, but its core function extends far beyond simple conveying. It is a continuous separation device based on the combined action of gravity, centrifugal force, and hydrodynamic forces. Material (mineral slurry) is fed from the top, and as it rotates and flows downwards along the spiral channel, mineral particles of different densities, sizes, and shapes experience different combined forces, causing them to spread laterally across the channel surface, achieving stratification and separation. Finally, concentrate, middlings, and tailings are obtained at different discharge ports.

Spiral chute structure diagram

In-Depth Analysis of the Working Principle

The separation process is a meticulously designed hydrodynamic dance:

1. Feeding and Distribution: The uniform mineral slurry is fed from the top and initially distributed tangentially.

2. Separation in a Composite Force Field: During the downward spiral motion, mineral particles are simultaneously subjected to:

◦ Gravity: The dominant force acting vertically downwards.

◦ Centrifugal Force: Generated by the rotational motion, directed towards the outer wall of the channel.

◦ Hydrodynamic Forces: Including friction at the bottom of the channel and water shear forces.

3. Stratification and Separation: Denser, finer particles (such as heavy metal minerals) tend to move towards the inner edge; less dense, coarser particles are thrown towards the outer edge. This process is continuously reinforced over several rotations.

4. Product Collection: At the bottom of the chute, a splitter separates the mineral streams of different grades into concentrate, middlings, and tailings troughs, completing the separation.

Why has the spiral chute remained relevant throughout the years? Interpretation of its Core Advantages

After 20 years of market and technological validation, spiral chutes have consistently maintained an important position among various gravity separation equipment, stemming from their unparalleled advantages:

Excellent Economy and High Efficiency

• No power consumption: Completely relies on gravity flow, requiring no transmission components or motors, resulting in extremely low operating costs.

• High processing capacity: A single unit can process a large amount of slurry, especially suitable for roughing and scavenging operations, with a significant enrichment ratio.

• Small footprint: Utilizes vertical space, resulting in high processing capacity per unit area.

Robust and Durable with Low Maintenance

• Simple structure: No complex moving parts, fewer failure points, and extremely high reliability.

• Strong wear resistance: The core chute surface can be made of high-molecular polyethylene, ceramic, or lined with wear-resistant rubber, ensuring a long service life.

• Easy operation: No complex operation or dedicated operators required, and minimal maintenance work.

Wide Environmental Adaptability

• Wide particle size adaptability: Especially suitable for processing fine-grained materials of -2mm, compensating for the shortcomings of jigs and other equipment in fine-grained recovery.

• Environmentally friendly: Usually requires no chemical additives, belonging to physical beneficiation, and is more environmentally friendly.

Success Story: Application of Spiral Chutes in Actual Production

In a large-scale coastal sand mining project, the client originally used traditional shaking tables to process fine-grained ilmenite minerals, which presented problems such as large footprint, high water consumption, and a large number of operators. We recommended and designed a five-head fiberglass spiral chute unit for roughing and enrichment.

• Application results: Under the condition of a feed particle size of -0.3mm, the processing capacity of a single unit reached 8-10 times that of the shaking table, and the ilmenite concentrate recovery rate increased by approximately 15%, while saving more than 60% of the workshop area and 30% of water consumption. After three years of operation, except for regular inspection of chute surface wear, no equipment failure or downtime occurred, bringing the client a very high return on investment. Related Equipment Recommendations: Building a Complete Gravity Separation Process

Spiral chutes rarely operate alone and are usually combined with the following equipment to form an efficient and coherent gravity separation process:

1. Spiral Feeder/Vibrating Feeder: Ensures uniform and stable feeding to the spiral chute, which is a prerequisite for guaranteeing separation efficiency.

2. Hydrocyclone: Used for classification and desliming, providing the spiral chute with a suitable feed particle size and avoiding interference from fine particles.

3. Shaking Table: As a refining device for the spiral chute, it further refines the middlings or coarse concentrates to obtain higher-grade final concentrates.

4. Slurry Pump and Piping System: Responsible for the transportation and connection of the slurry throughout the entire process.

Frequently Asked Questions (FAQ)

FAQ 1: Are spiral chutes and screw conveyors the same type of equipment?

No. Although the names are similar, their functions are completely different. A screw conveyor is purely a mechanical conveying device that uses rotating spiral blades to move dry or semi-fluid materials horizontally or at an incline. A spiral chute, on the other hand, is a separation device that works based on the principle of gravity separation of slurry, without any rotating blades.

FAQ 2: What factors affect the processing effect of a spiral chute?

The main influencing factors include:

• Ore properties: Slurry concentration, particle size distribution, and mineral density difference.

• Equipment parameters: Spiral diameter, pitch, cross-sectional shape and roughness of the chute surface, and number of turns (coils).

• Operating conditions: Feed rate and wash water volume. The optimal parameter combination needs to be determined through testing.

FAQ 3: How to maintain a spiral chute to maintain its best separation effect?

Maintenance is very simple:

1. Regularly inspect the chute surface: Check for wear, damage, or foreign object blockage, and clean or replace parts as needed.

2. Check connections: Ensure that there are no leaks at the connections of the feed pipe, splitter, etc.

3. For long-term shutdown: Clean thoroughly to prevent material deposition and hardening.