High-Frequency Vibrating Screen

In metal mine production, traditional classification and dewatering equipment is facing severe efficiency bottlenecks. Spiral classifiers suffer from low classification efficiency and large footprint, while ordinary vibrating screens are ineffective at handling fine-grained materials. These problems severely restrict the overall production efficiency of mines. High-frequency vibrating screens, as a technologically innovative piece of equipment, are becoming an important tool for optimizing the entire process from grinding to tailings in metal mines due to their unique working mechanism and superior performance. This article will delve into the application value of high-frequency vibrating screens in four key scenarios in metal mines.

I. Technical Principle Overview

High-frequency vibrating screens utilize high-frequency (typically 25-50Hz) and low-amplitude operating characteristics, generating micro-vibrations on the screen surface through vibration frequencies up to 3000 times per minute. Unlike traditional spiral classifiers that rely on gravity settling, high-frequency vibrating screens achieve efficient classification by directly applying vibration energy to the material.

Key Advantages Comparison:

• Classification Efficiency: Increased from 50-60% of traditional equipment to 80-90%

• Energy Consumption: Reduced by 30-40% compared to spiral classifiers

• Footprint: Reduced by over 50%

• Processing Capacity: Increased by 2-3 times for the same specifications

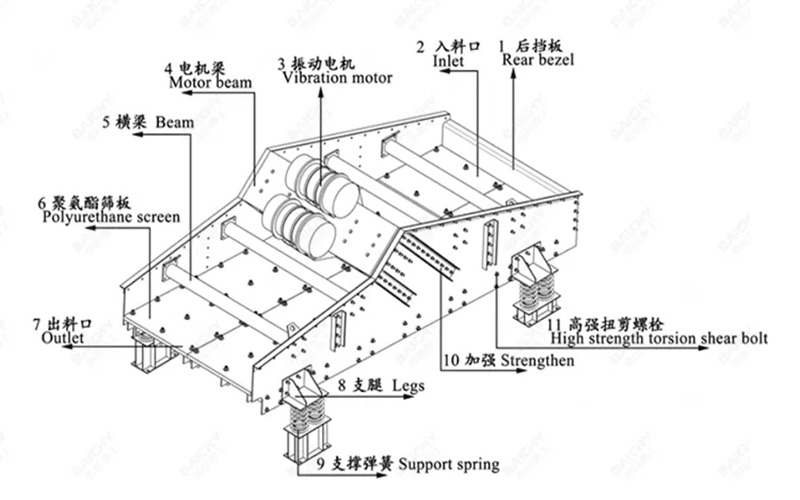

Dewatering vibrating screen structure diagram

II. Detailed Explanation of Core Application Scenarios

2.1 Grinding Loop Classification: An Efficiency Revolution Replacing Spiral Classifiers

Traditional Pain Points: Spiral classifiers in metal mine grinding loops have long suffered from low classification efficiency (typically 50-60%), high circulating load, and high energy consumption, resulting in the mill's capacity not being fully utilized.

High-Frequency Screen Solution: By installing a high-frequency vibrating screen to replace the spiral classifier, screening efficiency is significantly improved to 80-90%. A case study of an iron ore mine upgrade shows that the circulating load was reduced by 45%, the mill's processing capacity increased by 22%, and annual iron concentrate production increased by 150,000 tons, resulting in significant economic benefits.

2.2 Fine-Grain Pre-screening: The "Pre-filter" for Ball Mills

Innovative Process Logic: A high-frequency vibrating screen is installed before the ball mill to pre-remove qualified particles down to -0.5mm, effectively reducing over-grinding. This process change allows the ball mill to focus on coarse-grain grinding, significantly improving grinding efficiency.

Actual Results:

• Grinding efficiency increased by 10-20%

• Steel ball and liner consumption reduced by 15-25%

• Significant capacity release, particularly suitable for gold, copper, and other metal mines requiring fine grinding.

2.3 Tailings Dry Discharge Dewatering: An Environmental Transition from Wet to Dry Discharge

Environmental Pressure Conversion: Facing the safety and environmental risks of traditional wet tailings ponds, high-frequency dewatering screens provide an ideal solution. Through high-frequency vibration dewatering, the moisture content of tailings is reduced from 60-70% to 15-18%, achieving true dry storage.

Comprehensive Benefit Analysis:

• Tailings filter cake can be directly transported by truck, saving pipeline transportation costs.

• Water recycling rate reaches over 85%.

• Completely eliminates dam failure risk, meeting the requirements of green mine construction.

2.4 Optimization of the Beneficiation Process: Synergistic Effect with Magnetic Separation/Flotation

Process Integration Value: As a key piece of equipment in the process, the high-frequency vibrating screen improves the liberation degree of magnetic minerals before magnetic separation, increasing concentrate grade by 2-5%; it achieves narrow particle size intake before flotation, increasing flotation recovery rate by 3-8%. This synergistic effect systematically improves the efficiency of the entire process.

III. Selection and Implementation Guidelines

3.1 Key Parameters for Equipment Selection

• Vibration Parameters: Select a frequency of 25-50Hz and an amplitude of 0.5-3mm based on material characteristics.

• Screen Configuration: Polyurethane screens offer good wear resistance and a service life of 6-12 months.

• Processing Capacity Calculation: Consider factors such as feed concentration and particle size distribution, and design with a margin of safety.

3.2 On-site Application Precautions

• Ensure uniform feed and avoid uneven loading.

• Establish a screen wear monitoring system and regularly check screen integrity.

• Optimize process connections to ensure compatible operation with upstream and downstream equipment.

IV. Summary of Benefits and Future Trends

Significant Economic Benefits: Comprehensive calculations show that after adopting a high-frequency vibrating screen, energy consumption per ton of ore is reduced by 30%, production capacity is increased by more than 20%, and maintenance costs are reduced by 25%. The investment payback period is typically 12-18 months.

Technological Development Trends: The application of intelligent monitoring systems, new wear-resistant materials, and the trend towards larger equipment sizes will further enhance the performance and application range of high-frequency vibrating screens.

V. Conclusion

High-frequency vibrating screens have evolved from simple screening equipment into a core node in optimizing metal mine processes. Their strategic value lies in systematically improving the efficiency and effectiveness of the entire production process. With the deepening of green mine construction, the technological advantages of high-frequency vibrating screens will be more fully realized.

Appendix

Examples of Technical Parameters

| Model | Screen Area (㎡) | Vibration Frequency (Hz) | Processing Capacity (t/h) | Power (kW) |

| GZS1020 | 2 | 50 | 10-15 | 5.5 |

| GZS1530 | 4.5 | 48 | 25-35 | 11 |

Application Cases and Results

• A copper mine: Mill processing capacity increased by 18% after pre-screening

• A gold mine: Annual water savings of 500,000 cubic meters through tailings dry discharge

• An iron mine: Annual profit increased by 12 million yuan after full-process transformation

FAQ

Q1: How to prevent screen clogging when processing viscous materials using a high-frequency vibrating screen?

A: For viscous materials, the following measures are recommended: use a large-angle screen (usually 25-30°) to enhance material flowability; use polyurethane screens and optimize the aperture design (e.g., inverted conical apertures); configure bouncing balls or ultrasonic screen cleaning devices; appropriately reduce the feed concentration and control the uniformity of feeding.

Q2: What is the replacement cycle and cost of wear parts for high-frequency vibrating screens?

A: Under normal circumstances, the service life of polyurethane screens is 6-12 months, and the vibrator bearing life is about 2-3 years. Wear parts account for about 60% of the total equipment maintenance cost, but the replacement cycle can be significantly extended through optimized operation and regular maintenance. It is recommended to establish a preventative maintenance plan to reduce overall maintenance costs.

Q3: Are high-frequency vibrating screens suitable for processing dense metal ores?

A: Absolutely. The special design of high-frequency vibrating screens can effectively process dense metal ores. The key is to rationally select vibration parameters (frequency and amplitude) and configure a screen structure with sufficient strength. For extra-heavy ores, heavy-duty high-frequency screens can be selected, and the feed thickness can be appropriately reduced to ensure screening effect and equipment safety.

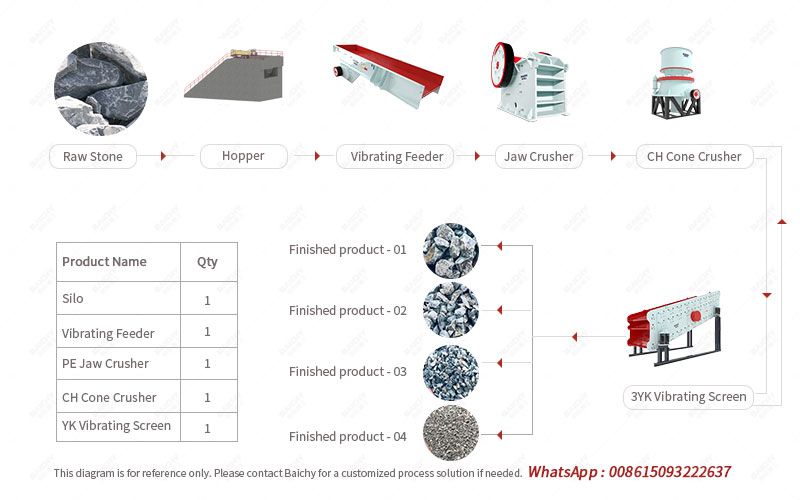

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!