HGM60 Micro Powder Mill Supplier | Grinding Solutions

In today's globalized building materials, chemical, and mining industries, efficient and reliable grinding equipment is at the core of the production chain. We have noticed that customers from Togo are actively seeking HGM60 micro-grinding mill equipment. As a manufacturer of mining crushing and grinding equipment with 20 years of experience, we deeply understand the urgent needs of customers in the African market, especially in Togo, for equipment durability, adaptability, and cost-effectiveness. This article will delve into how the HGM60 micro-grinding mill perfectly meets the unique requirements of the Togolese market and provide you with a comprehensive equipment analysis and professional advice.

| Key Words | HGM60 Micro Powder Mill Supplier |

|---|---|

| Product Name | HGM Micro Powder Mill |

| Feed Size | 0-20mm |

| Motor Power | 75-185kw |

| Capacity | 0.5-20.5t/h |

| Core Functions | The crushing and grinding action of the rollers. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Why do Togolese customers favor the HGM60 micro-grinding mill?

Togo and West Africa are experiencing rapid growth in infrastructure construction, agriculture, and mineral processing, leading to a growing demand for micro-grinding of materials such as calcium carbonate, barite, gypsum, and limestone. With its medium capacity, excellent fineness adjustment range, and superior stability, the HGM60 micro-grinding mill is an ideal choice for customers in the region to upgrade their production capacity and increase product added value.

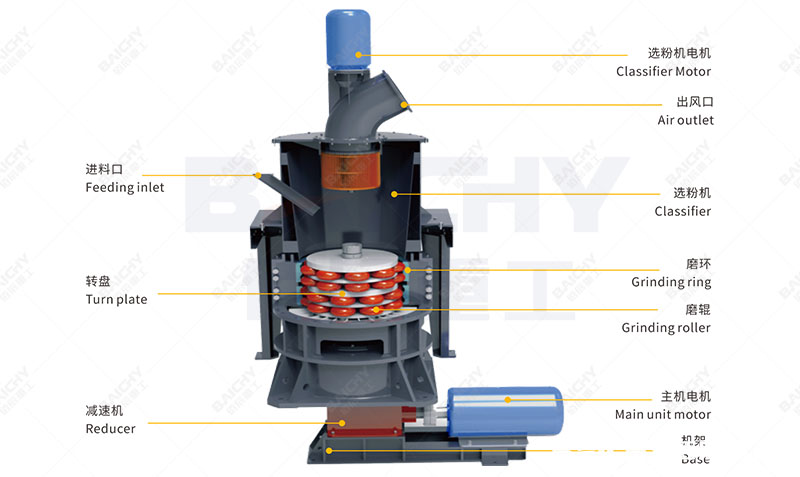

HGM micron mill structure diagram

Core Advantages of the HGM60 Micro Powder Mill

Leveraging twenty years of technological expertise, our HGM60 micro powder mill boasts multiple design and manufacturing advantages, ensuring stable operation under the complex working conditions of Togo.

Superior Adaptability and Durability

The main body of the equipment is manufactured using high-quality steel and special wear-resistant processes. Key grinding components such as grinding rollers and grinding rings utilize high-chromium alloys, resulting in an extremely long service life. This easily addresses the uneven material hardness issues that may exist in Togo, significantly reducing long-term maintenance costs and downtime for customers.

High-Efficiency Grinding and Classification Technology

The HGM60 micro powder mill employs a mature roller mill principle, combined with a high-efficiency turbine classifier. The finished product fineness can be flexibly adjusted between 150-2500 mesh, with high classification accuracy and excellent particle size distribution. This meets the stringent powder quality requirements of industries such as coatings, plastics, and papermaking, helping Togolese customers enhance their product competitiveness.

Environmentally Friendly and Low Operating Costs

The system features a compact design, operates under negative pressure, and minimizes dust leakage, aligning with environmentally friendly production principles. Meanwhile, the low energy consumption per unit product and low wear rate of vulnerable parts bring significant cost advantages and return on investment to Togolese customers from a long-term operational perspective.

HGM Micron Mill South Africa Project

Success Story: Supporting Mining and Processing in West Africa

We provided a complete HGM60 micronized powder mill production line for a customer in Lomé, Togo, to process the abundant local limestone deposits and produce heavy calcium carbonate powder for coatings. Over two years of operation, the production line has demonstrated extremely high stability, with the finished product fineness consistently maintained at 800 mesh, and the production capacity fully meeting design targets. The customer highly praised its low failure rate and excellent after-sales service. This case fully demonstrates the superior reliability of the HGM60 micronized powder mill in the humid and hot environment of Africa.

Related Equipment Recommendations

In addition to the core HGM60 micronized powder mill, a complete micronized powder production line usually requires supporting equipment to achieve efficient production. As a full-solution supplier, we recommend:

PE250x400 jaw crusher

• Jaw Crusher: Used for primary crushing of large raw materials.

• Bucket Elevator: Used for vertical material conveying within the production line.

• Electromagnetic vibrating feeder: Ensures uniform and stable feeding of material into the mill.

• Pulse dust collector: Efficiently collects dust, achieving clean production.

Frequently Asked Questions (FAQ)

1: What local Togolese materials is the HGM60 micro powder mill suitable for processing?

This equipment is ideal for processing non-flammable and non-explosive minerals with a Mohs hardness of 7 or less and a moisture content of 6% or less, such as limestone, calcite, barite, gypsum, feldspar, dolomite, etc., commonly found in Togo. Its applications are very wide-ranging.

2: Can the equipment operate normally in areas with unstable power supply?

We understand the infrastructure situation in some areas. The HGM60 micro powder mill can be adapted to motors of different power ratings, and we recommend that customers configure appropriate voltage stabilizers or protection devices. We can also provide customized power solution recommendations based on site conditions to ensure stable equipment operation.

3: How does the manufacturer provide after-sales support?

We provide comprehensive after-sales support to our global customers, including detailed installation instructions with drawings and videos, online remote engineer guidance, a fast supply channel for key spare parts, and the ability to arrange for engineers to travel to Togo for on-site installation, commissioning, and operation training, completely eliminating any concerns our customers may have.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!