Diesel Engine Hammer Mill Crusher | South Africa Zimbabwe

In African mining and infrastructure construction, particularly in resource-rich regions like South Africa and Zimbabwe, stable and reliable crushing equipment is the cornerstone of production operations. The South Africa Zimbabwe Diesel Engine Hammer Crusher is a key piece of equipment specifically designed to address the unique challenges of the region. Given the potentially unstable power grid coverage and the often remote locations of mining areas, the diesel engine drive provides independence from power limitations, ensuring continuous production. Furthermore, the hammer crusher is known for its simple structure, high crushing ratio, and strong adaptability, making it ideal for processing various medium-hard ores and construction materials commonly found in Africa.

Equipment Overview: The culmination of 20 years of professional manufacturing

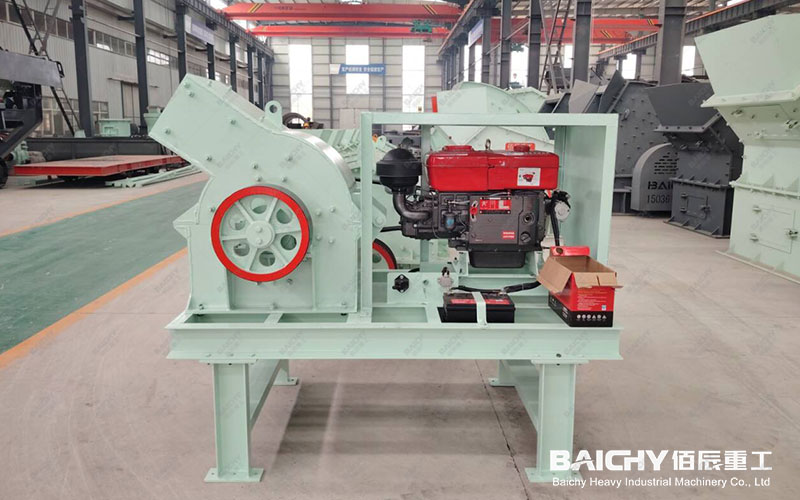

As a mining crushing equipment manufacturer with 20 years of experience, we deeply understand the demands placed on equipment in harsh working conditions. The diesel engine hammer crusher we offer is a deep integration of technology and experience. The entire machine features a heavy-duty design, with the core crushing components made of high-manganese steel hammerheads and wear-resistant liners. The diesel engine uses internationally renowned brands or can be customized according to customer needs, ensuring powerful performance and low failure rates. Its integrated design facilitates transportation and relocation, truly achieving ready to use, quick to start production, making it an efficient choice for both mobile and fixed crushing scenarios.

Diesel Engine Hammer Mill Crusher | South Africa Zimbabwe

Core Advantages: Why choose our equipment?

1. Exceptional Independence and Adaptability: Built-in diesel engine eliminates the need for external power, making it particularly suitable for remote mines and work sites with no or unstable power supply in regions like South Africa and Zimbabwe.

2. Powerful Crushing Capability: Heavy-duty hammerhead design provides high inertia force, efficiently crushing various materials such as limestone, bluestone, and coal gangue. The output particle size can be adjusted through the sieve plate to meet different customer needs.

3. Unparalleled Durability and Easy Maintenance: Based on 20 years of manufacturing experience, we have comprehensively reinforced key stress points. The compact structure and easily removable main components significantly reduce maintenance costs and downtime. 4. High Cost-Effectiveness and Return on Investment: Compared to electric equipment that relies on the power grid, the initial infrastructure investment is lower; the diesel engine provides direct power with minimal transmission loss, resulting in more advantageous overall operating costs in specific scenarios.

Application Case: On-Site Reliability Verification

In a medium-sized gold mining project in the Mashonaland region of Zimbabwe, the client faced challenges due to scattered sites and unstable power supply. We provided them with a diesel-powered hammer crusher with a capacity of 50 tons per hour for primary crushing of gold ore. The equipment was installed, commissioned, and put into production within three days of arrival. During 18 months of continuous operation, despite the harsh environment, the equipment maintained a high operating rate of over 90% thanks to its stable diesel engine performance and robust crushing structure, successfully completing production tasks and generating significant economic benefits for the client, earning high praise from the mine managers.

Related Equipment Recommendations

Mobile Jaw Crusher Diesel Crushing Station: If you have higher requirements for primary crushing output and material adaptability, this mobile equipment integrating feeding, crushing, and conveying is an ideal choice.

Heavy-Duty Vibrating Feeder: Used in conjunction with our hammer crusher, it provides uniform and continuous feeding, protects the crusher, enables automated control of the entire process, and significantly improves the overall production line efficiency.

Rotary Screen: After crushing, the material can be classified using a rotary screen to separate the finished product that meets the specifications, maximizing resource utilization.

Frequently Asked Questions (FAQ)

Q1: What is the approximate fuel consumption of this diesel hammer crusher?

A1: Fuel consumption depends on the equipment model, diesel engine power, and the hardness of the crushed material. Our equipment is optimized for efficiency and typically maintains industry-leading fuel economy under full load. You can provide your target output and material information, and our engineers will estimate more accurate energy consumption data for you.

Q2: What is the lifespan of key wear parts (such as hammer heads)? Is replacement complicated?

A2: The hammerheads are made of ultra-high wear-resistant alloy material, typically providing hundreds to thousands of hours of service life when crushing medium-hard materials. We have given full consideration to ease of maintenance; the hammerhead replacement design is simple, usually requiring only opening the inspection cover and using standard tools, significantly reducing maintenance downtime.

Q3: We are located in South Africa. Can you provide localized installation support and after-sales service?

A3: Absolutely. As an international manufacturer, we have established a service network or partnered with local professional teams in South Africa and major regions of Africa. We can provide detailed installation instruction drawings and remote support, and can also coordinate local technicians for on-site service, ensuring timely spare parts supply and safeguarding the continuous operation of your equipment.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.