Maintenance Essentials for Mobile Crushing Plants in Arid Regions

Maintenance of mobile crushing plants in arid regions requires special attention to dust and sand protection, heat dissipation management, lubrication and sealing, and structural corrosion prevention. The following are the specific key points:

I. Dust and Sand Protection and Sealing Management

1. Enhanced Sealing Protection

◦ Key areas: Focus on the seals of bearings, hydraulic cylinders, and transmission components (such as belts and gears). Check if the seals (such as lip seals and dust rings) are aging or worn, and replace them promptly with wear-resistant and anti-aging sealing materials.

◦ Additional dust covers: Install dust covers or soft curtains at dust-prone areas such as conveyor transfer points, screens, and feed inlets to reduce sand and dust intrusion.

◦ Electrical cabinet sealing: Ensure that electrical control cabinets and junction boxes are well-sealed, and regularly clean accumulated dust inside to prevent short circuits.

2. Air Filtration System

◦ Frequent cleaning/replacement: The air filters of the engine, hydraulic system, and air compressor need shorter maintenance cycles (possibly 2-3 times more frequent than in conventional environments). High-efficiency dry or oil-bath filters are recommended.

◦ Pre-filtration device: A pre-filter screen or cyclone dust collector can be added to the air intake to reduce the load on the main filter element.

II. Heat Dissipation and Temperature Control

1. Cooling System Maintenance

◦ Radiator cleaning: After shutdown each day or after each shift, check the radiators (water tank, hydraulic oil radiator, intercooler), and use compressed air or low-pressure water to blow them clean from the inside out to prevent blockage by lint and sand.

◦ Fan and belt: Check the tension of the fan belt to ensure cooling efficiency; the fan blades should be clean and free from deformation.

2. Oil Temperature Monitoring:

Closely monitor the temperature of hydraulic oil and lubricating oil to prevent oil degradation and seal aging due to high temperatures. If necessary, add additional radiators or use high-temperature-resistant oils.

III. Lubrication and Oil Management

1. Shortened Oil Change Cycle: Because sand and dust easily contaminate lubricating oil, the replacement cycle for hydraulic oil, gear oil, and grease should be shortened by 20%-30% compared to standard environments. The frequency of oil sample testing should be increased.

2. Targeted Cleaning and Lubrication: Before adding lubricating oil or hydraulic oil, the oiling port must be thoroughly cleaned to prevent sand particles from entering the system with the oil. The use of a centralized automatic lubrication system is recommended to reduce the risk of manual contamination.

3. Selection of Special Lubricants: Consider using synthetic or semi-synthetic oils with good viscosity-temperature characteristics, high-temperature oxidation resistance, and corrosion resistance.

IV. Structural Corrosion and Wear Protection

1. Rust Prevention Treatment: Regularly inspect the equipment casing and structural components (especially welds and connections), and promptly reapply corrosion-resistant coatings (such as epoxy zinc-rich primer + polyurethane topcoat) to areas where the paint film has peeled off.

2. Monitoring of Wear Parts: Due to the high quartz content in sand and dust, wear is accelerated in areas subjected to material abrasion, such as crusher hammers, liners, screens, and conveyor belts. The inspection cycle should be shortened, and a replacement warning mechanism based on tonnage produced should be established.

3. Bolt Tightening: Vibrations and temperature changes caused by wind and sand can easily lead to loose bolts. Regularly tighten bolts in critical areas (such as crusher rotors, screen bodies, and frame connections) according to torque requirements.

V. Daily Operation and Storage

1. Shutdown Protection: When the equipment is shut down for extended periods, cover key components such as the engine, control system, and conveyor articulation points with dust covers. Whenever possible, park the equipment in a sheltered area or construct a temporary windbreak.

2. Pre-Start Check: Before each start-up, check the engine intake pipe, radiator, oil level, and oil cleanliness, and remove any visible dust accumulation.

3. Tire Protection: High temperatures and sharp碎石 (crushed stones) can accelerate tire wear. Maintain appropriate tire pressure, avoid overloading, and lay steel plates or crushed stone layers on the work surface to reduce direct contact.

VI. Personnel and Records

• Specialized Inspection Checklist: Develop a specific inspection checklist for sandy and dusty environments, covering seals, filters, radiators, and wear parts.

• Operator Training: Train operators to master daily maintenance skills in sandy and dusty environments and cultivate the habit of "cleaning, sealing, and monitoring." Summary: The core principles of maintenance in arid regions are "sand prevention, heat dissipation, wear resistance, and corrosion prevention." By shortening maintenance cycles, strengthening sealing and filtration, and selecting consumables specifically suited to the environment, equipment uptime and lifespan can be significantly improved. It is recommended to communicate with the equipment manufacturer to obtain a specialized maintenance plan tailored to the local sandy and high-temperature environment.

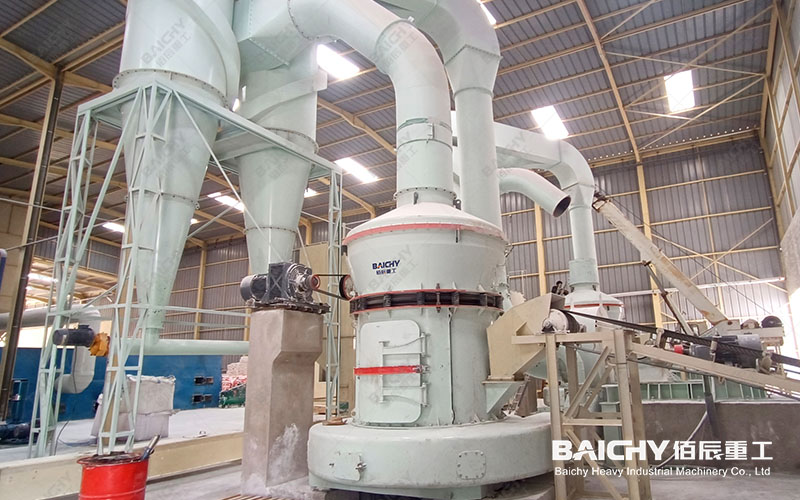

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!