Gravity Spiral Chute Conveyor - Hot Sale for Mining & Gold

In the increasingly competitive mining and gold extraction industry, improving sorting efficiency and reducing operating costs are core demands for every company. Our gravity spiral chute conveyor, a best-selling product resulting from our 20 years of experience in manufacturing mineral processing equipment, is a key solution to this challenge. With its unique design and efficient gravity separation principle, it has gained widespread recognition globally, becoming a reliable choice for recovering heavy minerals (such as gold, tungsten, tin, iron ore, etc.) from mineral sands.

Currently, mining development tends to process lower-grade ores, while environmental protection and energy consumption requirements are becoming increasingly stringent. The gravity spiral chute conveyor perfectly fits this trend. It requires no complex power system, relying solely on the gravity of the mineral slurry and the movement of water flow within the spiral chute to achieve separation, significantly reducing energy consumption. Its simple structure, small footprint, large processing capacity, and low operating costs make it an indispensable pre-treatment or roughing equipment in the mineral processing flow of many mines, especially gold mines, beach sand mines, and rare metal mines.

| Key Words | Gravity Spiral Chute Conveyor - Hot Sale for Mining & Gold |

|---|---|

| Product Model | Spiral Chutes |

| Feed Size | ≤0.02-0.3mm |

| Motor Power | -- |

| Capacity | 0.2-16t/h |

| Core Functions | Gravity is the fundamental driving force of the entire process. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Product Overview: Working Principle and Structure

How does the gravity spiral chute conveyor work?

The core of the gravity spiral chute conveyor is to utilize the difference in specific gravity between mineral particles for separation. The mineral slurry is fed from the top of the spiral chute, and as it flows downwards along the chute, the mineral particles are simultaneously subjected to the combined effects of gravity, centrifugal force, hydrodynamic force, and friction.

Key Separation Process

1. Stratification: As the slurry flows, high-specific-gravity heavy mineral particles settle to the lower layer of the slurry flow, while light mineral particles remain in the upper layer.

2. Zoning: Under the action of centrifugal force, the heavy mineral particles in the lower layer move towards the inner edge, while the light mineral particles in the upper layer are pushed towards the outer edge by the water flow.

3. Separation: Through the interceptors installed on the inner edge of the spiral chute, concentrates (heavy minerals), middlings, and tailings (light minerals) can be collected separately, thus achieving efficient separation.

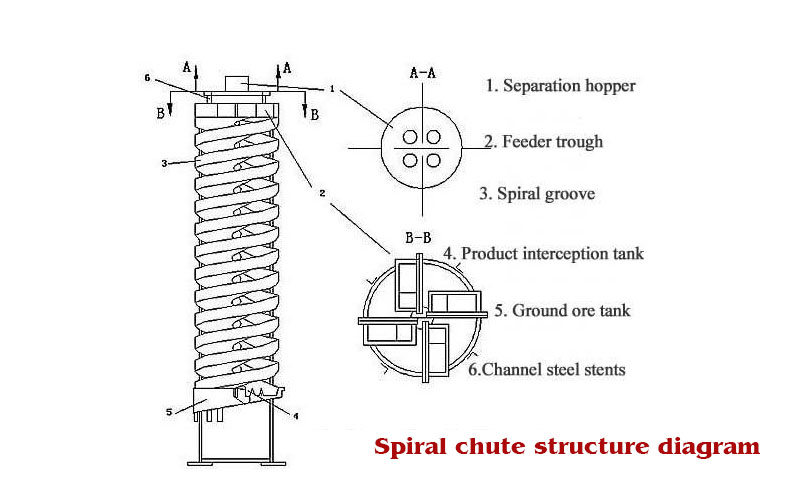

Spiral chute structure diagram

Core Advantages: Why choose our product?

With twenty years of dedicated technological expertise, our gravity spiral chute conveyors offer the following significant advantages:

• High Recovery Rate: Excellent recovery rate for minerals in the -2mm particle size range, especially gold ore, effectively reducing the loss of valuable metals.

• Extremely Low Operating Costs: Operates solely on gravity, requiring no power, significantly saving electricity; long service life of wear parts and simple maintenance reduce long-term costs.

• Robust and Durable Structure: The chute body is made of high-wear-resistant polyurethane or ceramic lining, resistant to corrosion and abrasion, adapting to harsh mining environments.

• Environmentally Friendly and Pollution-Free: Pure physical separation process, no chemical reagents required, environmentally friendly, and wastewater is easy to treat.

• Simple Installation and Operation: Modular design, quick on-site installation, easy adjustment of operating parameters, and low technical requirements for operators.

Successful Case Study

In a project at a large gold mine in West Africa, the client's original process had unsatisfactory gold recovery rates and high energy consumption. After adding our five-head gravity spiral chute conveyor for pre-concentration in their beneficiation process, they successfully removed over 40% of the light tailings in the roughing stage, significantly reducing the load on subsequent refining processes. Ultimately, the overall gold recovery rate increased by approximately 8%, while overall energy consumption decreased by 15%, resulting in a very short return on investment period. The client highly praised the results.

Related Equipment Recommendations

To build a more efficient and complete mineral processing production line, we recommend integrating the gravity spiral chute conveyor with the following equipment:

1. Jaw Crusher & Cone Crusher: To provide the appropriate feed particle size for the spiral chute.

2. Ball Mill: To further grind and liberate the ore, improving the separation effect.

3. Shaking Table: As a refining device for the spiral chute concentrate, further improving the concentrate grade.

4. Thickener & Filter Press: Used to treat the pulp after separation, achieving dewatering and water recycling.

Frequently Asked Questions (FAQ)

Q1: What type of ore is the gravity spiral chute conveyor best suited for?

A1: It is best suited for processing placer or vein deposits with good monomer dissociation and a large specific gravity difference between minerals and gangue, such as placer gold deposits, beach sand deposits (ilmenite, zircon), tungsten ore, tin ore, and some iron ores. For ores that are not sufficiently liberated, it needs to be used in conjunction with grinding equipment.

Q2: What are the processing capacity and particle size range of the equipment?

A2: The processing capacity of a single unit ranges from a few tons to hundreds of tons per hour, depending on the number and model of spiral heads. The optimal particle size range is typically 0.1-2mm. We can provide customized design and selection based on your ore properties and production requirements.

Q3: What should be paid attention to during daily operation and maintenance?

A3: Maintenance is very simple. The main tasks are to regularly check whether the feeding is uniform and stable, clean any potentially clogged feed pipes, and regularly check the wear of the spiral trough lining and interceptors and replace them promptly. Under normal circumstances, no dedicated operator is required.