Spiral Chute for Effective Gravity Separation in Mining

In modern mineral processing, efficiency and environmental protection are two core objectives. Gravity separation, as a time-tested mineral processing method with clear physical principles, is highly favored due to its lack of chemical reagents and low operating costs. The spiral chute is one of the key pieces of equipment for achieving efficient gravity separation. It cleverly utilizes the principle that mineral particles, under the combined action of gravity, centrifugal force, hydrodynamic force, and friction, separate based on differences in density, particle size, and shape, thus efficiently and continuously separating the target minerals.

| Key Words | Spiral Chute for Effective Gravity Separation in Mining |

|---|---|

| Product Model | Spiral Chutes |

| Feed Size | ≤0.02-0.3mm |

| Motor Power | -- |

| Capacity | 0.2-16t/h |

| Core Functions | Gravity is the fundamental driving force of the entire process. |

| Brand | Baichy Heavy Industry |

| Packing | Standard containers,Nude Packing,Wooden boxes, etc |

| Installation | Engineer Guide |

| Factory visit | Welcomed Warmly |

| Export Countries | Southeast Asia, Central Asia, South America, North America, Africa |

| Payment | T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. | |

Spiral Chute Overview: Structure and Working Principle

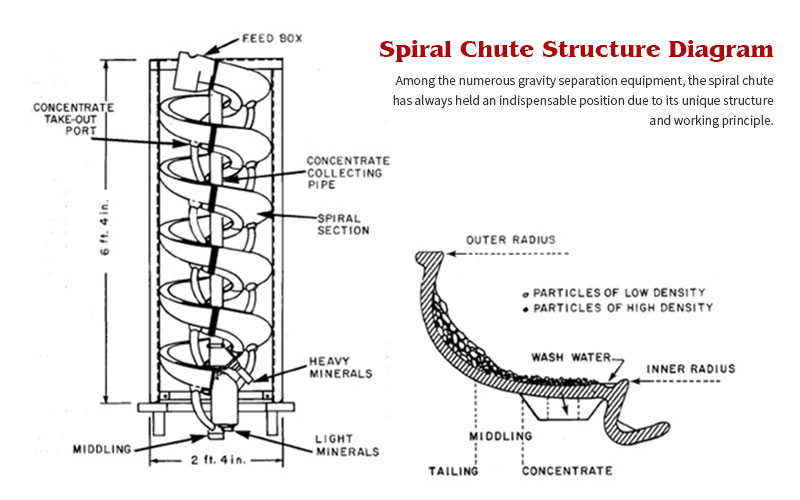

The spiral chute mainly consists of a feeder, spiral trough, central column, splitter, receiving trough, and frame. Its core component is a spiral-shaped trough that winds around a central column from top to bottom.

The working principle can be summarized as follows: After the slurry is fed from the top, the mineral particles are subjected to a complex force field as they flow down the spiral trough. Denser, appropriately sized heavy mineral particles settle faster and tend to move closer to the inner edge of the trough; while lighter mineral particles are pushed towards the outer edge by the water flow. A splitter installed at the end of the trough precisely separates the different mineral products (concentrate, middlings, and tailings) and directs them into their respective receiving troughs, thus achieving continuous separation.

Spiral chute structure diagram

Core Advantages of the Spiral Chute: Why Choose It?

As a manufacturer with 20 years of experience, we understand that the following advantages of the spiral chute are key to its enduring success:

Extremely Low Operating Costs, Energy-Saving and Environmentally Friendly

The equipment has no moving parts and is driven solely by gravity, requiring no power consumption. The separation process does not require the addition of chemical reagents, making it environmentally friendly and simplifying subsequent wastewater treatment.

Simple Structure, Convenient Maintenance

The spiral chute has a simple design with few components and a very low failure rate. Daily maintenance is minimal, requiring only periodic checks of the trough lining wear, significantly reducing operating and maintenance costs.

Large Processing Capacity, Stable Separation Efficiency

A single unit can achieve continuous feeding, separation, and discharge, providing high processing capacity per unit of land area. For minerals within a specific particle size range (especially 0.03-1mm), the separation efficiency and recovery rate are very stable and reliable.

Strong Adaptability

By adjusting parameters (such as pitch, diameter, and number of turns) and operating conditions (feed concentration, particle size), it can be flexibly applied to a variety of minerals, such as iron ore, tungsten ore, tin ore, ilmenite, chromite, gold ore, and beach sand deposits.

Successful Application Case: From Theory to Practice

We provided a complete spiral chute separation solution for a large beach titanium sand mining project in Southeast Asia.

• Challenge: The density difference between titanium minerals and gangue minerals such as quartz sand in the raw ore was small, and the processing volume was large, requiring stable and water-saving equipment.

• Solution: A multi-layer parallel GL series spiral chute system was adopted, designed as a roughing-scavenging-cleaning process.

• Results: Under the condition that 80% of the feed particle size was -100 mesh, both the grade and recovery rate of the titanium concentrate exceeded customer expectations. Compared with the originally intended jigging machine solution, water consumption was reduced by more to than 40%, and operating costs were reduced by 30%, earning high praise from the customer.

Related Equipment Recommendations: Building an Efficient Gravity Separation System

Spiral chutes are often used in conjunction with other equipment to create synergistic effects and build the most economical separation circuit:

• Paired with shaking tables: Spiral chutes perform roughing or pre-concentration, removing a large amount of tailings, while shaking tables refine the rough concentrate to obtain high-grade concentrate. This is a classic process for placer gold and tungsten-tin ores.

• Paired with centrifugal concentrators: For ultrafine particles, centrifugal concentrators can be used for recovery, and the enriched product can then be processed using spiral chutes.

• Pre-crushing and screening equipment: Ensuring that the mineral particle size fed into the spiral chute is within the optimal range is a prerequisite for maximizing its efficiency.

Frequently Asked Questions (FAQ)

What are the optimal feed particle size and concentration for spiral chutes?

Generally, spiral chutes perform best for particle sizes between 0.03-1mm. The feed concentration is typically between 20% and 40% solid weight concentration. The optimal conditions for a specific ore need to be determined through testing, as concentrations that are too high or too low will affect the separation efficiency.

What are the options for the trough lining of the spiral chute? What is their lifespan?

Common lining materials include wear-resistant polyurethane, ceramics, and ultra-high molecular weight polyethylene. We primarily recommend wear-resistant polyurethane lining, which offers excellent wear resistance, corrosion resistance, and self-cleaning properties. Under normal operating conditions, it has a lifespan of 2-5 years, significantly reducing replacement costs and downtime.

How to determine whether multiple units should be connected in series or parallel?

This depends on the process requirements. Parallel connection is used to multiply the processing capacity; series connection (such as primary roughing and secondary scavenging) is used to improve the recovery rate. The optimal equipment combination and process are usually determined through mineral processing tests.