On stone processing production lines, the first hurdle is crucial when dealing with hard, wear-resistant granite. Like a vanguard on a battlefield, it must possess immense strength and unwavering resilience. The core equipment shouldering this responsibility is the jaw crusher, hailed as the pioneer of crushing. This article will delve into why jaw crushers have remained a staple in the primary crushing of granite, becoming the preferred choice for many sand and gravel companies.

I. The Challenges of Granite: Why is Primary Crushing So Critical?

Granite, as an igneous rock, is renowned for its high hardness, high strength, and wear resistance. These characteristics make it a superior building material, but they also pose significant challenges to crushing equipment:

• High Hardness: With a Mohs hardness of 6-7, it causes extreme wear on crushing components.

• High Compressive Strength: Typically exceeding 200 MPa, requiring enormous crushing force to tear it apart.

• Dense Structure: Not prone to cracking, requiring continuous and stable high pressure for crushing.

Therefore, primary crushing equipment must not only provide enormous crushing force, but its own structure must also be extremely robust and durable to withstand the hard-on-hard confrontation with granite.

II. Jaw Crusher: A Workaholic Built for Hard Rock

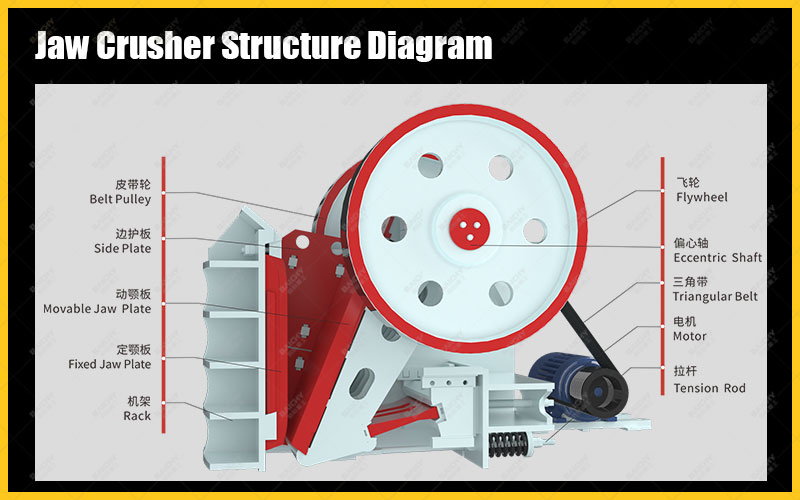

The working principle of a jaw crusher is simple and efficient, mimicking the movement of an animal's jaws. It mainly consists of two core components:

• Fixed Jaw Plate: A stationary jaw plate, like a strong tooth jaw.

• Moving Jaw Plate: A jaw plate that performs periodic reciprocating motion, like a powerful chin.

When granite raw material is fed into the feed inlet, the moving jaw plate periodically moves closer to and further away from the fixed jaw plate, squeezing and grinding the material trapped between the two jaw plates, thus breaking it apart. When the crushed material is smaller than the discharge opening, it is discharged under gravity, completing one crushing cycle.

III. Conquering Granite: The Four Core Advantages of Jaw Crusher

1. Powerful Crushing Force and Robust Structure

◦ The jaw crusher utilizes a high-quality cast steel frame and a heavy-duty eccentric shaft, resulting in an exceptionally robust structure capable of withstanding the enormous cyclic impact loads generated during granite crushing. Its V-shaped crushing chamber design provides immense compressive force instantly, easily crushing large pieces of granite.

2. Superior Wear Resistance

◦ Addressing the high abrasion characteristics of granite, the jaw plates are typically made of high-manganese steel or more wear-resistant alloy steel. These materials undergo work hardening under intense impact and compression, resulting in a harder and more wear-resistant surface, significantly extending the service life of vulnerable parts and reducing operating costs.

3. Wide Feed Adaptability and High Processing Capacity

◦ The jaw crusher features a large feed opening, easily accommodating large granite rough with a diameter exceeding one meter, eliminating the need for pre-blasting or excessive pretreatment. This makes it an ideal choice for primary crushing after mine blasting, with processing capacities ranging from tens to thousands of tons per hour, meeting the needs of production lines of various sizes. 4. Simple Structure and Reliable Operation

◦ Jaw crushers have a simple structure, are easy to maintain, and have a low failure rate. Their core power transmission is achieved through belts and an eccentric shaft, ensuring stable and reliable operation. Even in harsh mining environments, they can guarantee continuous operation, minimizing downtime.

IV. How to Choose the Right Jaw Crusher for Granite Crushing?

Choosing the right jaw crusher is half the battle. The following key parameters require close attention:

• Feed Size: Determined based on the maximum particle size of your granite raw material.

• Discharge Size: Adjust the discharge opening size according to the feed requirements of the next stage of crushing (such as a cone crusher).

• Processing Capacity: Matches the hourly output target of your entire production line.

• Motor Power: Ensures sufficient power for efficient granite crushing.

Tip: For hard rocks like granite, it is recommended to choose a heavy-duty or mining-grade jaw crusher, which is reinforced in structure and materials for greater durability.

V. Optimize Operation and Maintenance to Maximize Equipment Value

• Uniform Feeding: Avoid overloading or empty running of the equipment, ensure the crushing chamber is fully filled, improve efficiency, and reduce wear.

• Regular Jaw Plate Inspection: Carefully observe the wear of the jaw plates and rotate or replace them promptly to ensure optimal output particle shape and yield.

• Lubrication is Key: Strictly follow the manufacturer's requirements for regular and quantitative lubrication of key components such as bearings. This is the cornerstone of long-term equipment operation.

In conquering granite, the jaw crusher, with its inherent power, robust build, and simple intelligence, has rightfully become the stabilizing force in the primary crushing stage. Choosing a high-performance, high-quality jaw crusher is not only the beginning of efficient operation of your production line but also a crucial guarantee for long-term stable profits.

If you are planning a crushing solution for your granite quarry or sand and gravel aggregate project, please feel free to contact us. Our technical experts will provide you with the most professional equipment selection advice!