Can a Hammer Crusher Crush Granite

Can a hammer crusher crush granite? This is a key question for many mining and aggregate plant investors when selecting equipment. Granite, as a high-hardness, high-wear-resistant igneous rock, has a Mohs hardness of 6-7 and a compressive strength typically exceeding 100 MPa, posing a serious challenge to the hammer head material, rotor kinetic energy, and casing structure of crushing equipment.

As a mining crushing equipment manufacturer with 20 years of experience, we can definitively answer: Optimized and reinforced hammer crushers can be used to crush granite, but not all general-purpose models are suitable; technical reinforcement specifically tailored to its high-hardness characteristics is required.

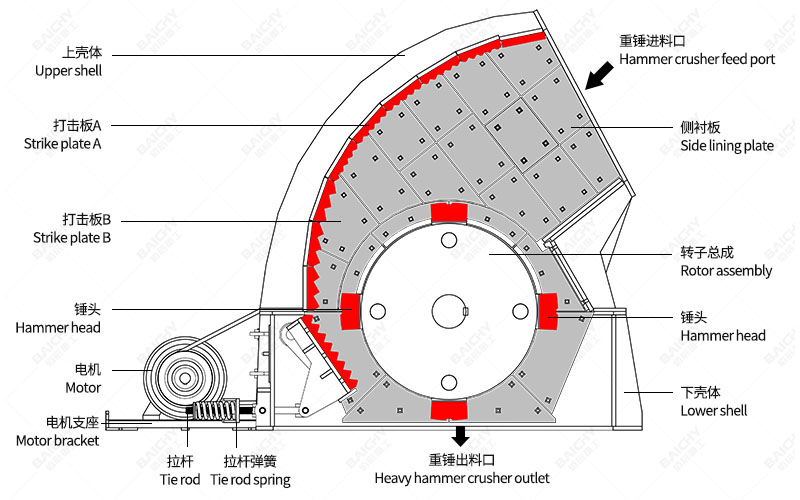

Heavy-duty hammer crusher structure diagram

Working Principle of Hammer Crushers for Crushing Granite

Hammer crushers primarily achieve crushing by using a high-speed rotating rotor to drive the hammer heads, impacting, striking, and cutting the material. When used for crushing granite, the working process has the following characteristics:

1. High Kinetic Energy Impact: The rotor needs a higher rotational speed and greater mass to generate sufficient impact kinetic energy to crush high-hardness granite.

2. Multiple Crushing: After being impacted by the hammer heads inside the machine, the material is thrown against the impact liner for further crushing, creating a combined crushing effect of hammering and impact.

3. Grate Screening: The crushed material of acceptable size is discharged through the grate openings, while oversized particles remain in the chamber for further crushing, ensuring controllable output particle size.

Unique Advantages of Hammer Crushers for Crushing Granite

Compared to the conventional process of using a jaw crusher for primary crushing followed by a cone crusher for secondary and fine crushing, introducing a reinforced hammer crusher offers significant advantages in certain operating conditions:

| Advantage | Specific Description |

| Multi-purpose machine, simplified process | For medium-sized and smaller mines with non-extreme granite hardness, a heavy-duty hammer crusher can replace both jaw and cone crushers, significantly reducing equipment, civil engineering, and maintenance investment. |

| Excellent Product Particle Shape | The impact crushing principle results in finished aggregate that is mostly cubic, with low flaky and elongated particle content and a reasonable gradation, significantly improving concrete strength and market price. |

| Relatively Convenient Maintenance | Replacing wear parts such as hammer heads is faster than replacing the mantle and concave of a cone crusher, resulting in shorter downtime and improved overall production line uptime. |

| Suitable for Materials with Some Moisture Content | Compared to cone crushers, it is less sensitive to the moisture content of the material and has some adaptability in high-humidity environments. |

Success Story: Application of Our Equipment in Granite Crushing

Case Background: A large building materials group in East China, with an annual production capacity of 5 million tons of aggregate, using medium-hardness granite as the raw material.

Pain Points: The original two-stage crushing process (jaw crusher + cone crusher) was lengthy, the cone crusher had high maintenance costs, and the flaky and elongated particle content of the finished product needed improvement.

Solution: Our company customized a PCZ-1820 heavy-duty hammer crusher as the core equipment for secondary crushing.

Key reinforcement measures included:

- Using dual-alloy composite hammer heads, with the hammer tip made of ultra-high chromium alloy for good impact toughness; the hammer handle is made of high-toughness alloy steel to prevent fracture.

- The rotor underwent special dynamic analysis and counterweighting to ensure stable operation and long bearing life.

- The impact liner material was upgraded to high-wear-resistant cast steel.

Results: The production line process was simplified, overall power consumption was reduced by approximately 15%, the finished aggregate had excellent particle shape with flaky and elongated particle content below 8%, and the equipment ran stably, achieving the expected return on investment.

Related Equipment Recommendation

If your material is granite of higher hardness or larger size, we recommend the golden combination of multi-stage crushing:

1. Primary Crushing: PE series deep-cavity jaw crusher, achieving stable and efficient coarse crushing of granite.

2. Medium and Fine Crushing Optimization: Our company's PCG series powerful hammer crushers are designed for high-hardness materials, or the HPG series multi-cylinder hydraulic cone crushers are used for applications with extremely high production and particle size requirements.

3. Shaping and Sand Making: PLS series vertical shaft impact crushers (sand making machines) are used to produce high-quality manufactured sand.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of hammer heads when crushing granite with a hammer crusher?

A1: This depends on the specific SiO2 content of the granite, the crusher model, rotor linear speed, and hammer head material. Using our company's specially designed dual-alloy hammer heads, the service life can reach 400-800 hours under typical working conditions. By regularly rotating the working surface of the hammer heads, their wear resistance can be fully utilized.

Q2: What is the controllable output particle size when processing granite with a hammer crusher?

A2: By adjusting the gap of the bottom grate bars, our enhanced hammer crushers used for crushing granite can typically maintain a stable output particle size of 25-40mm or less. If finer products are required, a closed-circuit system with a vibrating screen can be used, or a sand making machine can be configured at the back end.

Q3: Compared to cone crushers, what are the operating costs of using a hammer crusher to crush granite?

A3: Both have their advantages. Hammer crushers typically have lower single-machine equipment investment and initial costs, and the wear parts (hammer heads) are cheaper and easier to replace. Cone crushers may have advantages in terms of energy consumption per ton and steel consumption per ton in long-term operation, especially for ultra-high hardness, high-capacity production lines. The specific choice requires a technical and economic comparison based on investment budget, production requirements, long-term operational planning, and the physical properties of the ore.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.