Ore Processing Gold Stone Hammer Mill

In the field of ore processing, especially in the primary crushing stage of gold ore, hammer crushers have always played a crucial role. Gold ore typically exhibits characteristics such as uneven hardness, high clay and moisture content, and dense structure, which place demands on crushing equipment for impact resistance, wear resistance, and resistance to clogging.

Small hammer crushers, thanks to their unique structure and working principle, are an ideal choice for small and medium-sized gold ore processing plants, experimental production lines, or mobile crushing stations. They crush materials through the impact of high-speed rotating hammers, achieving a high one-pass crushing rate and effectively reducing the load on subsequent crushing stages.

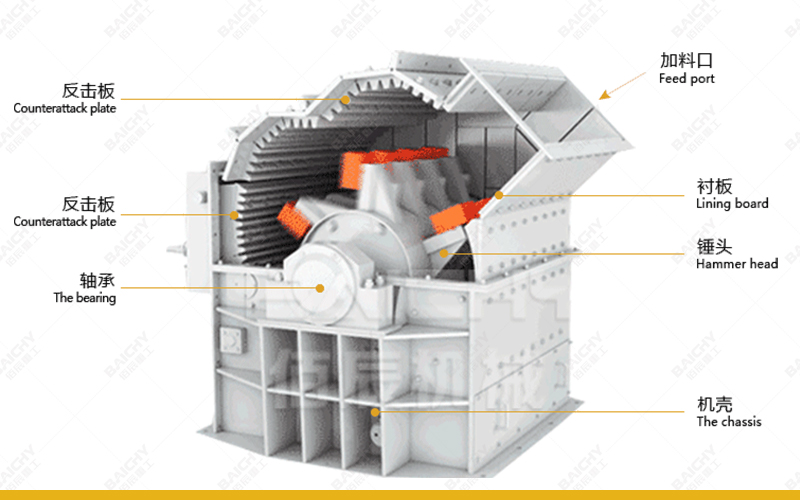

PC Hammer Crusher Customer Structure Diagram

Core Features of Small Hammer Crushers

Small hammer crushers are a compact design of traditional hammer crushers, typically referring to models with a processing capacity of 5-100 tons/hour, a compact structure, and a small footprint. Their core components include the rotor, hammers, crushing plates, screen plates, and drive device.

- Working Principle: After the material enters the crushing chamber, it is crushed by the impact of high-speed rotating hammers. Material that meets the required particle size is discharged through the screen plate openings at the bottom, while oversized particles remain in the chamber to be further impacted and ground by the hammers until they pass through the screen plate.

- Structural Advantages: Simple and compact structure, easy operation and maintenance, and low investment cost, making it particularly suitable for gold mining projects with limited funds or small processing volumes.

Ore Processing Gold Stone Hammer Mill

Exclusive Advantages: Competitiveness Forged by 20 Years of Manufacturing Experience

As a mining crushing equipment manufacturer with 20 years of R&D and manufacturing experience, we deeply understand the pain points of gold ore crushing and have continuously optimized our small hammer crushers:

1. High Efficiency and Wear Resistance, Doubled Lifespan: Using high-chromium alloy composite hammers, we have optimized the material and heat treatment process for high-hardness minerals such as gold ore quartz veins, resulting in wear resistance that is more than 50% higher than ordinary hammers.

2. Easy Particle Size Control, Excellent Product Shape: By adjusting the screen plate gap, the output particle size can be flexibly controlled (usually controllable to below 10-30mm), resulting in uniform particle size and a high cubic content, which is beneficial for subsequent grinding and leaching.

3. Powerful Performance, Lower Energy Consumption: Optimized rotor dynamics design results in greater impact energy at the same power level, reducing energy consumption per unit of product by approximately 15% compared to the industry average.

4. Sealed and Dustproof, Environmentally Compliant: Enhanced bearing chamber and housing sealing design effectively suppresses dust leakage, resulting in a cleaner working environment and meeting environmental production requirements.

5. Strong Adaptability, Unaffected by Sticky and Wet Materials: For gold ore containing mud and water, a non-clogging screen plate and adjustable crushing chamber have been designed, significantly reducing material sticking and downtime due to clogging.

Application Case: Successful Practice at a Gold Ore Processing Plant

Project Background: A medium-sized hard rock gold mine in China, with a maximum ore size of 300mm and medium-to-high average hardness, containing a small amount of clay. The original process used two-stage crushing with a jaw crusher and a cone crusher, resulting in a long process and high investment.

Solution: We recommended a small heavy-duty hammer crusher as a single-stage crushing solution. This equipment has a large feed opening and can directly process raw materials from mining trucks, achieving single-stage crushing, more crushing and less grinding.

Results:

- Processing capacity is stable at 45-50 tons/hour, with an output particle size controlled at ≤25mm.

- Directly replaced the original single-stage jaw crusher and two-stage cone crusher, significantly simplifying the process.

- The equipment operates stably, and due to the expected wear on the hammer heads from crushing hard gold ore, the hammer head lifespan met the expected production cycle.

- Overall power consumption and operating costs decreased by approximately 30%, significantly shortening the investment payback period.

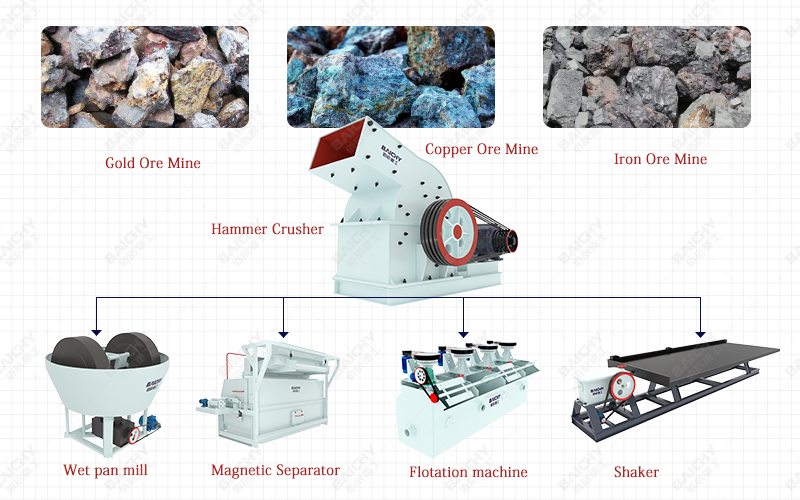

Related Equipment Recommendations

Small hammer crushers are often combined with the following equipment to form an efficient gold ore pretreatment production line:

- Feeding Equipment: Vibrating feeder for uniform and stable feeding, protecting the hammer heads.

- Screening Equipment: Trommel screen or vibrating screen for pre-screening or closed-circuit screening to improve system efficiency.

- Fine Crushing Equipment: If finer products are required, a fine jaw crusher or roller crusher can be used.

- Conveying Equipment: Belt conveyor to connect various process stages.

Frequently Asked Questions (FAQ)

Q1: Is the small hammer crusher suitable for processing all types of gold ore?

A1: It is very suitable for gold ore with medium to low hardness and non-extremely high abrasiveness (such as quartz vein type). For extremely hard (such as high-grade ore containing a large amount of quartz) or particularly viscous ores, a process evaluation is required in advance, or a customized reinforced hammer head should be selected.

Q2: What is the replacement frequency and cost of the hammer heads?

A2: This depends on the ore hardness and processing volume. For typical gold ore, our high-chromium alloy hammer heads can usually process tens of thousands of tons of material. Replacement only requires opening the inspection door, the operation is simple, and downtime is short.

Q3: Does the equipment require a special installation foundation?

A3: A sturdy concrete foundation is required to withstand the vibrations during equipment operation. We provide detailed foundation drawings and installation instructions. The overall steel structure base of the equipment can also simplify installation.

Q4: Can it be combined with a mobile chassis to form a mobile crushing plant?

A4: Yes. We provide crawler or wheeled mobile chassis integration solutions, which are very suitable for gold exploration or small and medium-sized mining projects with scattered mining areas and frequent relocation needs, enabling crushing on the go.

Q5: How fine can the output particle size be adjusted?

A5: By replacing screen plates with different apertures, the minimum output particle size can generally reach about 10mm. If finer output is required, a two-stage configuration of hammer crusher + fine crusher is recommended.

Q6: As a 20-year-old factory, what kind of after-sales service do you provide?

A6: We provide comprehensive pre-sales technical support, free process layout design, professional installation guidance, and operation training. The equipment has a one-year warranty, and we provide lifelong technical support and sufficient spare parts supply to ensure worry-free production for our customers.

Perfect after-sales service

Baichy Heavy Industry provides professional on-site guidance for installation, training of workers, and other services to ensure that customers can use the equipment smoothly.

The company has a complete after-sales service system, which can provide customers with timely technical support and equipment maintenance services to ensure the long-term stable operation of the equipment.

To prevent the rights and interests of customers from being infringed, Baichy Heavy Industry reminds customers: please contact our customer service staff through the official website of Baichy Heavy Industry , or add WhatsApp: 15093222637 ; or send an email to: [email protected] , we will get in touch with you as soon as possible and provide you with the most professional service in the industry.

Baichy Heavy Industry

Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plants. We can offer you a free design and completed solutions according to your project.

Baichy Heavy Industry has grown into a high-tech mining equipment comprehensive enterprise, integrating R&D, manufacturing, sales, and after-sales service, Passing ISO9001:2015 quality management system certifications. The main products are mobile jaw crushing plants, construction waste crushing plants, PE jaw crushers, VSI sand-making machines, Symons cone crushers, single-cylinder hydraulic cone crushers, PCX high-fine crushers, grinding mills, ball mills, and full sets of beneficiation equipment with an excellent level.