In the highly competitive mining, aggregate processing, and metallurgical sintering industries, selecting efficient and reliable crushing equipment is crucial to determining production efficiency and profit margins. Among numerous crushing solutions, the double-roll crusher, with its unique advantages such as simple structure, low over-crushing rate, and convenient maintenance, has always held an irreplaceable and important position. As a seasoned mining equipment expert, this article will guide you through an in-depth understanding of this core weapon, helping you make the wisest decision in equipment selection.

I. What is a Double-Roll Crusher?

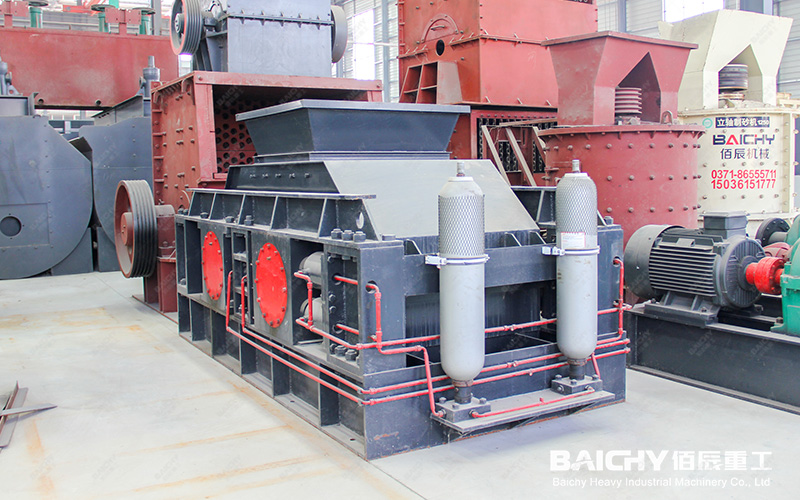

A double-roll crusher, as the name suggests, consists of two parallel-mounted rollers as its core working components. During operation, two motors (or transmission devices) drive the two rollers to rotate in opposite directions. The material to be crushed enters from above the rollers and is drawn into the gap between the rollers (i.e., the discharge port) under the action of friction and gravity. As the rollers rotate, the material is subjected to increasing compressive and shearing forces, eventually being crushed into particles smaller than the discharge port size, which then fall out under gravity.

This simplicity over complexity design philosophy makes it an ideal choice for medium-hard and lower-hard materials, especially suitable for applications with strict requirements on particle shape and over-grinding.

II. Why is a Twin Roll Crusher Your Wise Choice?

1. Precise Particle Control: The gap between the two rollers determines the maximum output particle size. By simply adjusting the gap, the particle size can be precisely and flexibly controlled, ensuring uniform finished product specifications and a reasonable gradation, greatly enhancing the added value of the product.

2. Extremely Low Over-Grinding Rate: Compared to crushers that rely on impact and collision principles (such as impact crushers and hammer crushers), twin roll crushers primarily crush materials through static pressure and shear force, producing less stone powder and needle-like particles. This is crucial for customers requiring high-quality aggregates, such as commercial concrete plants and asphalt mixing plants.

3. Robust Structure and Easy Maintenance: The overall structure is compact, and core components such as the roller skin are typically made of high-manganese steel or composite alloy materials, offering strong wear resistance and a long service life. 4. Minimum Routine Maintenance Points: Replacing easily worn parts like rollers or bearings is simple, minimizing downtime and reducing overall operating costs.

5. Sensitive and Reliable Overload Protection: Typically, one roller is designed to slide, protected by a strong spring. When uncrushable materials (such as iron blocks) enter the chamber, the spring compresses, increasing the roller gap and expelling the object, effectively protecting the core components of the main unit from damage and ensuring extremely high safety.

6. High Adaptability and Wide Application: Double-roll crushers can handle a wide range of materials, from coal, limestone, and sintered ore to coke and pebbles. By changing the rollers with different tooth shapes (such as wolf teeth or weld overlay teeth), they can easily adapt to different material properties and crushing requirements.

III. Main Types and Selection Guide for Double-Roll Crusher

Based on actual needs, double-roll crushers are mainly pided into the following types:

• Smooth Double-Roll Crusher: Relying on compression and grinding action, it is suitable for fine crushing of hard, abrasive materials, producing finer particle sizes.

Double-Roll Crusher

• Toothed Double Roll Crusher: Featuring raised teeth, it combines splitting and crushing actions, offering a large crushing ratio and suitable for coarse and medium crushing of sticky or medium-hard materials.

Key Selection Parameters: When selecting a crusher for your project, please focus on: feed particle size, output particle size requirements, processing capacity (tons/hour), and material characteristics (hardness, moisture content, viscosity). Provide this information to your equipment supplier, who will recommend the most suitable roll diameter and width models.

IV. Beyond the Equipment Itself: Choosing Us Means Choosing a Long-Term Partner

We understand that you are not just buying a machine, but a commitment to production stability and return on investment. As a company with many years of experience in the mining equipment industry, we offer not only high-quality double roll crushers, but also comprehensive value enhancement:

• Customized Solutions: We provide one-on-one equipment selection and production line configuration solutions based on your specific working conditions and capacity targets.

• Excellent After-Sales Service: We provide rapid spare parts supply, professional technical guidance, and regular equipment inspections to ensure your equipment is always in optimal operating condition.

• Continuous Technical Support: We share the latest industry trends and equipment optimization solutions to help your business maintain its leading position.

In today's pursuit of high efficiency, energy saving, and environmental protection, the double roll crusher, with its classic and efficient design, remains an indispensable key piece of equipment in many niche markets. Whether you are processing building aggregates, mineral raw materials, or industrial materials, a thorough understanding of double roll crushers will provide strong support for your cost reduction and efficiency improvement efforts.

Contact us today for customized technical solutions and quotations. Let our expertise safeguard your success!