How to Choose High-Efficiency and Durable Sand Washing Equipment

In sand and gravel aggregate production lines, after crushing and screening, sand washing machines play a crucial role as both "beauticians" and "quality inspectors." They are not merely for cleaning, but also the ultimate guarantee of sand and gravel product quality. Unwashed manufactured sand or natural sand contains excessive mud powder, stone powder, and impurities, which will seriously affect the strength, workability, and durability of concrete. Therefore, investing in a high-efficiency sand washing machine is an inevitable choice to increase product added value and meet the high-standard construction sand requirements.

How Does a Sand Washing Machine Work?

The core principle of a sand washing machine is that the rotation of an impeller or spiral device causes the sand and gravel to continuously tumble and rub in the washing tank. Simultaneously, the impact of water flow peels off the mud and impurities covering the surface of the sand particles, which are then discharged with the overflow wastewater. The clean sand and gravel are then discharged from the outlet under the drive of the blades or spiral, completing the washing, dewatering, and grading process.

Introduction to Mainstream Sand Washing Machine Types

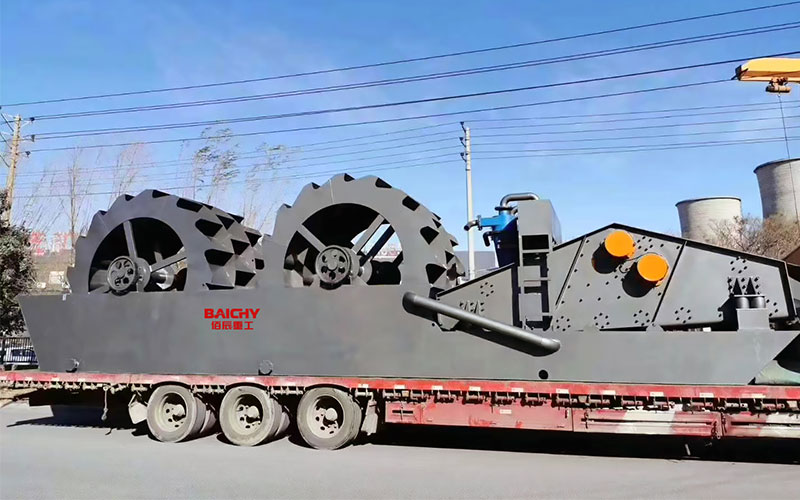

1. Wheel Bucket Sand Washing Machine: Compact structure, high washing efficiency, also features dewatering function, high water recycling rate, suitable for washing fine-grained materials.

2. Spiral Sand Washing Machine: Large processing capacity, strong washing ability, especially suitable for difficult-to-wash materials, and also has excellent grading effect.

3. Composite Sand Washing and Recycling Integrated Machine: Combines sand washing and fine sand recycling functions, effectively reducing fine sand loss (loss rate can be reduced to 5%-10%), increasing output and economic benefits, and is currently a very popular type of sand washing machine.

Core Advantages of Choosing Our Sand Washing Machine

With 20 years of experience in mining equipment manufacturing, our sand washing machines embody the essence of continuous innovation in technology and processes.

• Superior Washing Effect: Optimized blade design and rotation speed ensure thorough washing of sand and gravel, resulting in finished sand with low mud content and clean particle shape.

Key Advantages of Choosing Our Sand Washing Machine

With 20 years of experience in mining equipment manufacturing, our sand washing machines incorporate the essence of continuous innovation in technology and processes.

Superior Washing Effect: Optimized blade design and rotation speed ensure thorough washing of sand and gravel, resulting in finished sand with low mud content and clean particle shape.

• Highly Efficient Fine Sand Recovery: The patented dewatering screen and fine sand recovery device significantly reduce fine sand loss, solving the problems of low output and unreasonable gradation in traditional sand washing machines.

• Durability and Longevity: Core components such as impellers, reducers, and bearing housings are made of high-strength materials from well-known brands, offering strong wear resistance, low equipment failure rate, and long service life.

• Energy Saving and Environmental Protection: The design emphasizes water recycling, resulting in low water consumption; the well-sealed structure reduces dust emission, meeting environmental protection production requirements.

• Easy Maintenance: Modular design allows for easy inspection and maintenance of key parts, effectively reducing your long-term operating costs.

Successful Case Sharing

Case Study: A Large Green Building Materials Production Base in East China

This customer's original production line produced manufactured sand with unstable powder content, affecting sales prices. We configured two LZ-36 composite sand washing and recovery integrated machines for them. After implementation:

• The powder content of the finished sand is stably controlled at 5%-8%, meeting the national standard for medium sand in Zone II.

• Fine sand recovery rate exceeds 90%, saving over 150,000 RMB in economic losses monthly.

• The equipment operates smoothly and is easy to maintain. Customers are highly satisfied with the overall profitability and product competitiveness of the production line.

Recommended Equipment Combinations

An excellent sand washing machine requires perfect coordination with upstream equipment. We recommend:

• Combining with a sand making machine (vertical shaft impact crusher): This is the most common "golden combination." The output from the sand making machine directly enters the sand washing machine, producing high-quality manufactured sand.

• Combining with a vibrating screen: Pre-screening before washing separates materials of different particle sizes, improving the washing efficiency and targeting of the sand washing machine.

• Combining with a fine sand recovery device/dewatering screen: Forming a closed-loop cycle maximizs resource utilization, a strength of our integrated solutions.

Frequently Asked Questions (FAQ)

1: Does the sand washing machine consume a lot of water? How to achieve environmental protection?

Modern, high-efficiency sand washing machines are typically equipped with sedimentation tanks or fine sand recovery systems. The washing water, after sedimentation and flocculation, can be recycled, resulting in very little actual water replenishment. Typically, only a small amount of water needs to be added per hour to compensate for evaporation and water carried away by the finished sand, achieving environmentally friendly and energy-saving production.

2: What if the processed sand has a high moisture content?

Our wheel-type and composite sand washing machines integrate high-efficiency dewatering screens. Before discharge, the washed sand undergoes multi-layer linear vibration dewatering, controlling the moisture content of the finished sand to approximately 10%-15%, allowing for direct stockpiling or loading for transportation.

3: How to choose the appropriate sand washing machine model based on production capacity?

Choosing the right sand washing machine model depends primarily on your hourly production needs, the mud content of the raw material, and the required specifications of the finished sand. Our engineers can provide professional selection solutions and production line configuration suggestions based on your specific working conditions (such as material characteristics, budget, site conditions, etc.) to ensure maximum equipment efficiency.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!