Magnetic Separator

Introduction

In the complete process flow of mining crushing and mineral processing, the crushing system is responsible for breaking down raw materials, while the magnetic separator plays a crucial role as a "mineral sorter." As a professional manufacturer of mobile crushing equipment for mines, we deeply understand the close coordination between front-end crushing and back-end separation processes. This article will systematically explain how the magnetic separator—a core equipment that utilizes the natural magnetic differences between minerals to achieve efficient and clean separation—precisely captures high-value components from mixed materials, becoming a powerful engine for improving the economic and environmental benefits of mining operations.

Overview of Magnetic Separator Technology

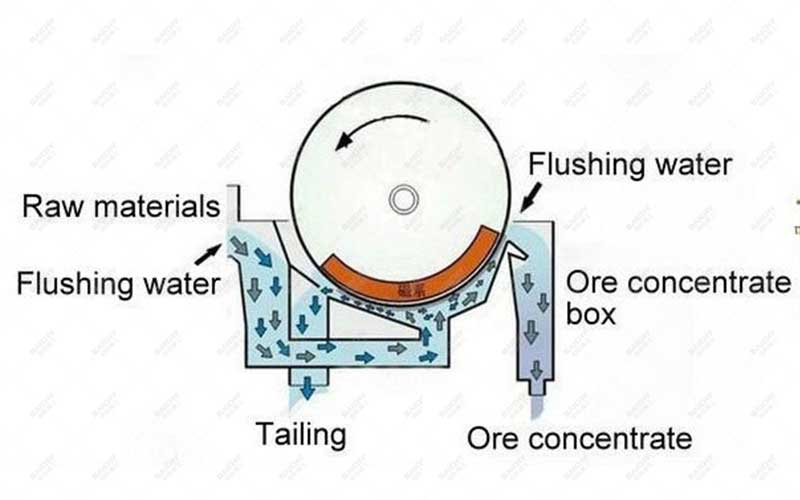

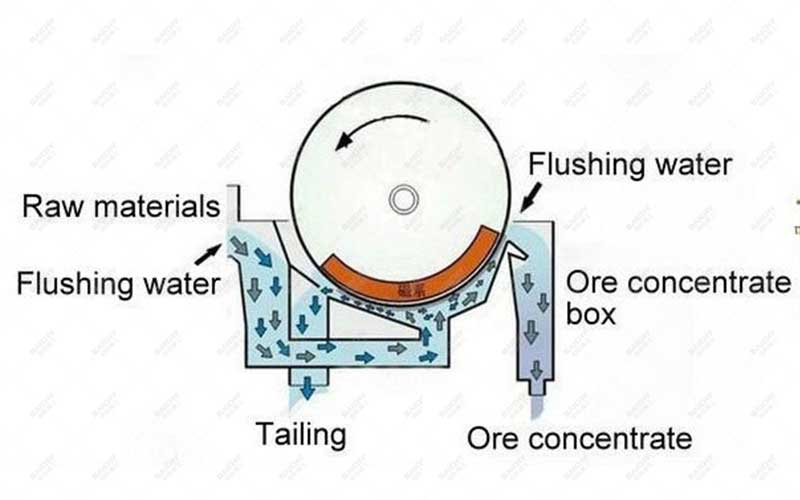

A magnetic separator is a mineral processing equipment that separates minerals based on the differences in their magnetic properties. Its core working principle is to utilize the magnetic force generated by the magnetic system. When mineral particles (usually in the form of dry powder or slurry) pass through the working area, magnetic minerals are attracted or deflected by the magnetic force, while non-magnetic (or weakly magnetic) minerals move along their original trajectory under the action of gravity, centrifugal force, or water flow, thus achieving physical separation of the two materials. Based on magnetic field strength, separation medium, and working method, magnetic separators are mainly divided into various types, including dry magnetic separators, wet magnetic separators, permanent magnet magnetic separators, electromagnetic magnetic separators, and high-gradient magnetic separators, which are widely used in the purification and impurity removal of ferrous metals, some non-ferrous metals, and non-metallic minerals.

| Key Words |

HGM60 Micro Powder Mill Supplier |

| Product Name |

Magnetic Separator |

| Magnetic field intensity (oe) |

1450-1650 |

| Motor Power |

1.1-11kw |

| Capacity |

8-200t/h |

| Core Functions |

By utilizing the magnetic differences between materials, magnetic and non-magnetic substances can be separated in a non-uniform magnetic field. |

| Brand |

Baichy Heavy Industry |

| Packing |

Standard containers,Nude Packing,Wooden boxes, etc |

| Installation |

Engineer Guide |

| Factory visit |

Welcomed Warmly |

| Export Countries |

Southeast Asia, Central Asia, South America, North America, Africa |

| Payment |

T/T,L/C payment,Paypal...etc |

| Please note: The above table data is for reference only. For specific information, please contact us. |

Core Advantages of Magnetic Separators

Among numerous separation technologies, magnetic separators have become an indispensable standard configuration in the field of mineral processing due to their unique advantages.

Efficient and Precise Physical Separation

The magnetic separation process does not require the addition of chemical reagents; it is a completely physical separation, avoiding chemical pollution. Modern magnetic separators, especially high-gradient and rare-earth permanent magnet machines, can generate high-intensity and high-gradient magnetic fields, efficiently recovering fine-grained (even micron-sized) magnetic minerals, resulting in high separation accuracy and recovery rate.

Low Operating Costs and Environmentally Friendly

The main energy consumption of the equipment is in driving the rotation of the magnetic system and the cylinder (or roller). Permanent magnet magnetic separators, in particular, consume almost no electricity to maintain the magnetic field during operation. The entire process does not produce toxic or harmful wastewater or exhaust gases, and the tailings are easy to treat, fully meeting the requirements of green mining and sustainable development. It is an extremely environmentally friendly separation method.

Strong adaptability and wide range of applications

The application of magnetic separators has long surpassed traditional iron ore separation. From strongly magnetic magnetite to weakly magnetic hematite, manganese ore, and ilmenite, to the iron removal and purification of non-metallic minerals (such as quartz, feldspar, kaolin, and sillimanite), and even the recovery of iron from industrial waste (such as steel slag and fly ash), various types of magnetic separators can be found. Their flexible configuration can meet the needs of different process stages, from roughing and scavenging to fine separation.

Application Case Analysis

Case 1: High-efficiency iron enrichment in a magnetite concentrator

In a large magnetite concentrator, the raw ore is processed by our provided mobile crushing and screening system before entering the first stage of grinding. The ground product first undergoes rough separation using a CTB series permanent magnet drum magnetic separator, pre-removing approximately 40% of the qualified tailings, greatly reducing the subsequent workload. After regrinding, the rough concentrate enters a multi-stage magnetic separation process. By optimizing the magnetic field strength and flushing water, high-quality iron concentrate with an iron grade exceeding 68.5% is finally obtained, with a total iron recovery rate as high as 96%. This case demonstrates the dominant efficiency of magnetic separators in the separation of strongly magnetic minerals.

Case 2: Deep iron removal and purification of quartz sand

A high-quality glass sand producer requires the Fe₂O₃ content in the raw material to be below 0.015%. After crushing and grinding the raw sand, a fine processing process centered on a "high-gradient magnetic separator" is used. Under the action of a high-intensity pulsed magnetic field and a steel wool matrix, extremely fine iron- and titanium-containing impurities (such as hematite, ilmenite, and tourmaline) in the raw sand are strongly captured, and the non-magnetic pure quartz sand passes through smoothly. After treatment by this magnetic separator, the product's Fe₂O₃ content is stably below 0.012%, meeting the high-quality glass sand standard, and the product value is significantly increased. This demonstrates the key role of special magnetic separators in the deep processing of non-metallic minerals.

System Synergy: Optimized Configuration from Mobile Crushing to Magnetic Separation

An efficient and low-cost mineral processing system begins with a synergistic design of the entire process. We recommend an integrated solution of "mobile pre-crushing + grinding and classification + targeted magnetic separation":

Front-end Mobile Crushing and Pre-tailing: Deploy our "mobile jaw crusher + cone crusher/impact crusher + mobile screening station" combination near the mining site or raw material stockpile. A dry magnetic separation drum (magnetic pulley) can be integrated into the mobile screening station to pre-separate already liberated waste rock or low-grade ore before the material enters the grinding process, achieving "early rejection of waste." This significantly reduces the feed volume and energy consumption of subsequent grinding and main magnetic separators, optimizing overall process costs from the source.

Mid-section Grinding and Preparation: The pre-treated material enters a ball mill for fine grinding, ensuring sufficient liberation of the target minerals from the gangue, creating the necessary conditions for subsequent efficient magnetic separation. The ground product can be controlled to the appropriate particle size for separation using classification equipment (such as hydrocyclones).

Back-end Core Magnetic Separation and Concentration: Multiple stages and types of magnetic separators are configured based on the magnetic properties of the minerals and product requirements. For example, medium-field strength permanent magnet drum-type magnetic separators are used for rough separation, while high-field strength magnetic separators or high-gradient magnetic separators are used for fine separation, forming an efficient magnetic separation circuit to maximize recovery rate and concentrate grade.

Mobile Jaw Crusher

Mobile Impact Crusher

Mobile Cone Crusher

Mobile Screening Station

Frequently Asked Questions (FAQ)

Q1: How do I choose the right type of magnetic separator based on my ore properties?

A1: The selection mainly depends on the magnetic properties (magnetic susceptibility) of the target mineral and the particle size of the processed material.

Strongly magnetic minerals (such as magnetite): Usually, medium-field strength, high-throughput permanent magnet drum-type magnetic separators (CTB/CTS series) are used.

Weakly magnetic minerals (such as hematite, limonite, wolframite): Higher field strength permanent magnet roller-type magnetic separators or electromagnetic magnetic separators are required.

Fine-grained minerals or non-metallic mineral impurity removal: High-gradient magnetic separators or superconducting magnetic separators capable of generating extremely high magnetic field gradients are required. Dry separation or pre-concentration: Dry permanent magnetic drum separators or dry permanent magnetic roller separators can be used. The final selection should be based on detailed ore magnetic analysis and separability test reports.

Q2: What are the main differences and application scenarios of wet and dry magnetic separators?

A2: The core difference lies in the separation medium and applicable scenarios.

Wet magnetic separator: Uses water as the medium to process ore slurry. Advantages: High separation accuracy, no dust, suitable for fine-grained materials (usually less than 2mm), and is the mainstream separation method. Applications: Most mineral wet separation processes, especially for beneficiation operations.

Dry magnetic separator: Separates dry mineral particles in air. Advantages: No water required, suitable for arid regions; the product is dry powder, no dewatering needed. Disadvantages: Prone to dust generation, requiring dust removal equipment; relatively sensitive to material moisture content and particle size. Applications: Areas with water scarcity, naturally dry materials, or situations requiring dry powder products; often used for pre-concentration and tailings removal in crushing and screening processes.

Q3: What aspects should be paid attention to in the daily maintenance of magnetic separators?

A3: Good maintenance is key to ensuring the long-term stable operation of the magnetic separator.

Regular inspection: Regularly check the wear of the wear-resistant layer (such as rubber lining) on the surface of the magnetic drum or magnetic roller, and repair or replace it in time to prevent scratching.

Bearing lubrication: Strictly lubricate the main shaft bearings according to the regulations to ensure smooth operation.

Cleaning and iron removal: Regularly clean the accumulated ore powder and debris on the surface of the equipment and surrounding areas. For wet magnetic separators, check whether the nozzles are clogged. For dry magnetic separators, ensure that the dust removal system is working properly.

Magnetic field strength monitoring: For permanent magnet machines, although the magnetic field decay is very slow, it is still recommended to regularly use a gaussmeter to detect the magnetic field strength to ensure that it meets the process requirements. For electromagnetic machines, the coil cooling system and power supply stability need to be checked.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!