Dolomite

Dolomite, hardness 3.5-4, specific gravity 2.85-2.9, widely distributed in nature. Dolomite is a carbonate mineral, including iron dolomite and manganese dolomite. Dolomite is generally off-white in color and is similar in appearance to limestone. Commonly called dolomite refers to relatively pure dolomite with a calcite content of less than 5%. It can be used in building materials, ceramics, glass and refractory materials, the chemical industry, agriculture, environmental protection, energy saving, and other fields.

| Fineness | Application Scenario | recommended equipment |

| Within 200 mesh | It is commonly used by customers to make putty powder, which can be used as feed additive (with calcium content above 55.6 and no harmful ingredients); | MTW Grinding Mill |

| 250-300 mesh | Used as raw materials for plastics, rubber factories, paint factories, and waterproof material factories, as well as interior and exterior wall paint (whiteness above 85 degrees); | MTW Grinding Mill |

| 350-400 mesh | Used in the manufacture of gussets, downpipes, and chemicals (whiteness above 93 degrees); | Vertical Roller Mill |

| 400-600 mesh | Can be used for toothpaste paste, soap (whiteness above 94 degrees); | Vertical Roller Mill |

| more than 800 mesh | For rubber, plastic, cable, PVC (whiteness above 94 degrees) | Vertical Roller Mill |

| more than 1250 mesh | It can be used as raw material for PVC, PE, paint, coating-grade products, paper-making primer, paper-making top coat, and ink. | Vertical Roller Mill |

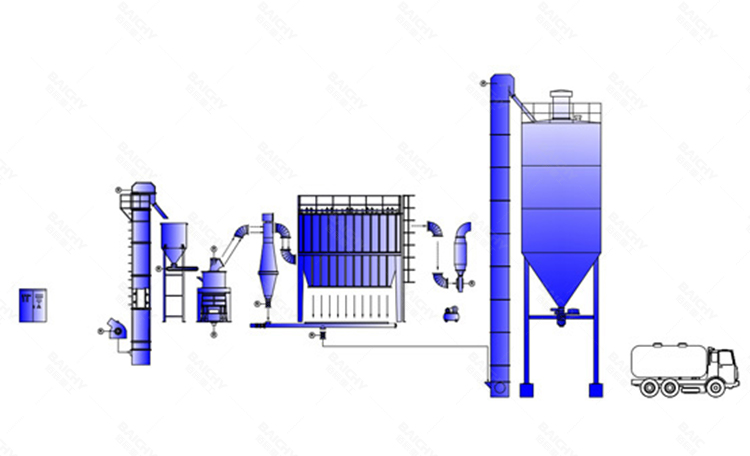

Dolomite Processing Technology

1. Crushing stage: large pieces of material are crushed by the crusher to the feed fineness that can enter the mill (15mm-50mm)

2. Milling stage: The small pieces of materials that meet the grinding conditions are uniformly and quantitatively entered into the grinding chamber of the mill through the conveying and feeding system, and are ground into powder in the grinding chamber.

3. Classification stage: The ground materials are classified through the powder classifier with the system airflow, and the unqualified powder is classified by the classifier and returned to the main mill for re-grinding.

4. Powder collection stage: the fine powder enters the powder collection system with the airflow through the pipeline, the air and powder are separated, and the finished powder is sent to the finished product silo by the conveying device, and then uniformly packed with a powder tanker or an automatic packing machine.

Recommended machines for Dolomite grinding mill

According to different uses and different discharge fineness, the choice of Dolomite mill will also be different.