Calcite

Calcite is widely distributed, with a hardness of 2.7--3.0 and a specific gravity of 2.6-2.8. It is also called stalactite, stalagmite, white marble, etc. The main component of calcite is calcium carbonate, and its main use is to make heavy calcium powder and light calcium powder. Calcite powder with different finenesses is widely used in papermaking, medicine, the chemical industry, agriculture, and other fields. Heavy calcium is closely related to people's lives. In the past 10 years, the annual production capacity of heavy calcium in the world has grown at an average growth rate of 5% to 8%, while the average annual growth rate of heavy calcium in China can reach 10%. Calcium powder processing is still a sunrise industry.

| Fineness | Application Scenario | recommended equipment |

| Within 325 mesh | Common customers are used to making putty powder, ordinary 325 mesh is fine, and it is also used as industrial raw materials such as chemical industry and cement. Calcite is used as a flux in the metallurgical industry and used to produce cement and lime in the construction industry. Used as a filling additive in food. When calcite is added to glass production, the resulting glass will become translucent, especially suitable for glass lampshades. | MTW Grinding Mill |

| 400-800 mesh | Used to make high-quality putty powder, and can also be used in plastics, paper, toothpaste, soap, etc.; | Vertical roller mill |

| More than 800 mesh | For rubber, plastic, cable, PVC (whiteness above 94 degrees) | Vertical roller mill |

| More than 1200 mesh | It can be used as raw material for PVC, PE, paint, coating-grade products, paper-making primer, paper-making top coat, and ink. | Vertical roller mill |

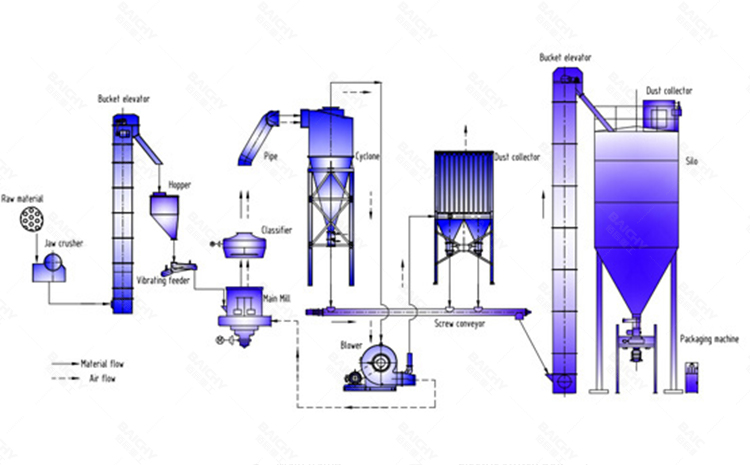

Calcite processing technology

1. Crushing stage: large pieces of material are crushed by the crusher to the feed fineness that can enter the mill (15mm-50mm)

2. Milling stage: The small pieces of materials that meet the grinding conditions are uniformly and quantitatively entered into the grinding chamber of the mill through the conveying and feeding system, and are ground into powder in the grinding chamber.

3. Classification stage: The ground materials are classified through the powder classifier with the system airflow, and the unqualified powder is classified by the classifier and returned to the main mill for re-grinding.

4. Powder collection stage: the fine powder enters the powder collection system with the airflow through the pipeline, the air and powder are separated, and the finished powder is sent to the finished product silo by the conveying device, and then uniformly packed with a powder tanker or an automatic packing machine.

Recommended machines for Kaolin grinding mill

According to different uses and different discharge fineness, the choice of Kaolin mill will also be different.