Petroleum coke

Petroleum coke is the crude oil that is distilled to separate the light and heavy oils, and then the heavy oil is thermally cracked to convert the product. It is the final "waste" in the petroleum refining process. According to different forms, it can be divided into four types: needle coke, pellet coke or spherical coke, sponge coke, and powder coke. So far, petroleum coke has not been included in the national energy sequence, and the national energy consumption statistics have not been included in the energy consumption index. Substituting petroleum coke for heavy oil as fuel is also a good way for new energy applications, and it also responds to the country's policy.

| Materials | Fineness | Application Scenario | recommended equipment |

| Needle coke | 200 mesh | After being made into powder, due to the low resistance and thermal expansion coefficient of needle coke, it is commonly used as an anode and carbon plant. | MTW Grinding Mill |

| Shot coke or spherical coke | 200 mesh | It can be used as a raw material for burning in ceramic factories and glass factories, and the economic benefits that can be obtained by using petroleum coke powder as fuel instead of heavy oil can be calculated based on the current market price of 2300 yuan/ton for petroleum coke powder and 4800 yuan/ton for heavy oil. According to the calorific value conversion of petroleum coke powder and heavy oil, one ton of heavy oil is equivalent to the heat generated by 1.2 tons of petroleum coke powder. The kiln consumes 5 tons of heavy oil per day. | MTW Grinding Mill |

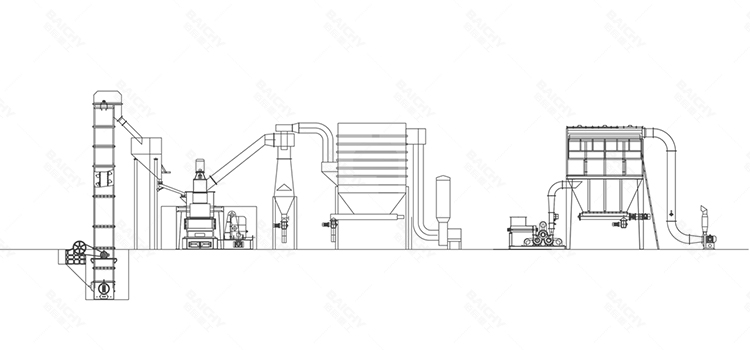

Petroleum coke processing technology

1. 1. Crushing stage: large pieces of material are crushed by the crusher to the feed fineness that can enter the mill (15mm-50mm)

2. Milling stage: The small pieces of materials that meet the grinding conditions are uniformly and quantitatively entered into the grinding chamber of the mill through the conveying and feeding system, and are ground into powder in the grinding chamber.

3. Classification stage: The ground materials are classified through the powder classifier with the system airflow, and the unqualified powder is classified by the classifier and returned to the main mill for re-grinding.

4. Powder collection stage: the fine powder enters the powder collection system with the airflow through the pipeline, the air and powder are separated, and the finished powder is sent to the finished product silo by the conveying device, and then uniformly packed with a powder tanker or an automatic packing machine.

Recommended machines for Kaolin grinding mill

According to different uses and different discharge fineness, the choice of Kaolin mill will also be different.