Basalt, a hard and highly abrasive igneous rock, is an indispensable high-quality aggregate raw material in the infrastructure industry. However, its "hardness" also poses serious challenges to crushing equipment and technology. Improper crushing methods can lead to severe equipment wear, soaring production costs, and poor finished product particle shape.

Stone Crushing Plant PDF, Download ↓↓↓

I. Understanding the Challenges: The Difficulties of Basalt Crushing

• High Hardness and High Abrasiveness: Basalt has a high SiO2 content and extremely high hardness, causing very rapid wear on vulnerable parts of crushing equipment (such as jaw plates, hammers, and side guards).

• High Crushing Costs: Frequent replacement of vulnerable parts not only increases spare parts costs but also leads to prolonged production line downtime, severely impacting production efficiency.

• Finished Product Particle Shape Requirements: High-quality manufactured sand and aggregates require a cubic particle shape with low needle-like and flaky content. Traditional crushing processes struggle to simultaneously meet the requirements of high output and high quality.

II. Core Solution: Primarily "Layered Crushing" with Optimal Equipment Configuration

Given the characteristics of basalt, the most economical and efficient solution is a multi-stage crushing combination of a jaw crusher and a cone crusher. The core principle is to reduce wear by utilizing the "layered crushing" principle.

1. Coarse Crushing Stage (Jaw Crusher): As the first stage, the jaw crusher, with its powerful crushing force and high reliability, is well-suited for the primary crushing of basalt. Its deep "V"-shaped crushing chamber design effectively improves feeding capacity, laying the foundation for subsequent crushing.

2. Medium and Fine Crushing Stage (Cone Crusher): This is the core of the entire solution. The cone crusher uses the layered crushing principle, achieving crushing through the mutual compression and grinding between particles, significantly reducing the wear rate of vulnerable parts such as the hammer. For basalt, it is recommended to use a hydraulic cone crusher or a multi-cylinder hydraulic cone crusher. These crushers allow for easy adjustment of the discharge port and cleaning of the chamber, offering a high degree of automation and greatly improving production stability and safety while ensuring particle shape.

3. Shaping and Sand Making Stage (Impact Crusher): To produce high-quality manufactured sand, an impact crusher (vertical shaft impact crusher) can be added after the cone crusher. It utilizes the principles of "stone-on-stone" and "stone-on-iron" crushing, effectively shaping the aggregate, reducing the content of needle-like and flaky particles, and resulting in more rounded sand particles with a more reasonable gradation.

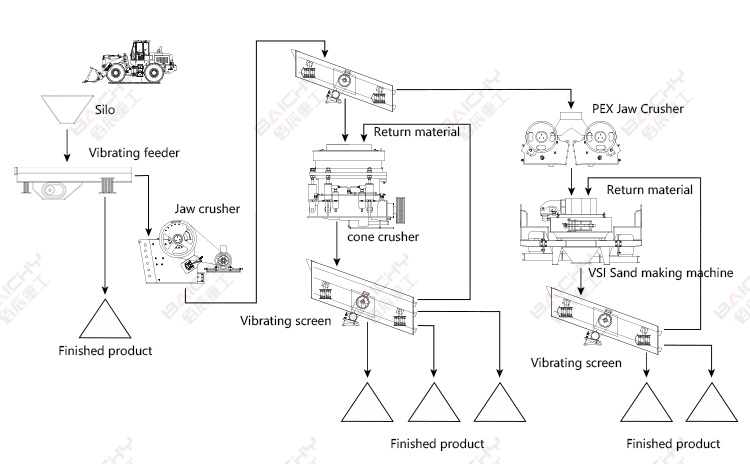

III. Recommended Classic Process Flow:

Feeding → Jaw Crusher (Coarse Crushing) → Cone Crusher (Medium Crushing) → Cone Crusher/Impact Crusher (Fine Crushing/Shaping) → Vibrating Screen (Screening) → Finished Aggregate/Manufactured Sand

IV. Advantages of Our Solution:

• Wear-resistant Materials: Key wear parts are made of ultra-high manganese steel or composite alloy materials, extending service life by more than 30%.

• Energy-saving and High-efficiency: Optimized cavity design results in high crushing efficiency and low energy consumption.

• Excellent Finished Product: The finished aggregate has excellent particle shape and continuous gradation, fully meeting the standards for high-grade highway, railway, and construction sand and gravel.

• Comprehensive Support: From site planning and equipment selection to installation, commissioning, operation, and maintenance, we provide one-stop professional services.

Conclusion: When facing hard basalt, choosing a scientific crushing solution and reliable equipment is key to success. We are committed to providing you with the most economical and stable overall basalt crushing solution, helping you reduce costs, increase efficiency, and create greater value.