In the mining machinery industry, we often encounter a seemingly simple yet crucial question: Which crusher is more suitable for crushing river pebbles? As a marketing expert and equipment supplier with many years of experience in the industry, my answer is always: There is no single 'best answer,' only the 'optimal solution' that best suits your specific working conditions and expected return on investment.

River pebbles, as a type of natural hard rock (usually granite, basalt, etc.), are characterized by high silica content, high hardness, and high wear resistance. However, their smooth surface makes them prone to slippage during crushing, causing severe abrasion to the equipment. Therefore, when selecting crushing equipment, we must comprehensively consider the crushing principle, production efficiency, wear and tear on vulnerable parts, and overall cost. Below, we will analyze the two mainstream medium crushing equipment—jaw crushers and cone crushers—from both technical and commercial perspectives.

I. Technical Showdown: Jaw Crusher vs. Cone Crusher

1. Jaw Crusher: The Pioneer in Coarse Crushing

• Working Principle: Utilizes the squeezing and bending force between the moving and stationary jaw plates, simulating the jaw movement of an animal to crush materials.

• Applicable to River Pebble Stage: Primarily used as primary crushing (coarse crushing) equipment. It crushes large river pebbles (e.g., diameter over 500mm) to an intermediate particle size of approximately 100-250mm.

• Advantages:

◦ Simple Structure, Robust and Durable: Mature equipment design, strong adaptability to harsh working conditions, and convenient maintenance.

◦ Large Feed Opening, No Material Pickiness: Easily handles river pebbles of varying sizes without strict pre-screening.

◦ Low Purchase Cost: Initial investment is more advantageous compared to cone crushers.

• Disadvantages:

◦ Poor Particle Shape: The output material has a high content of flaky particles and a low content of cubic particles, making it unsuitable for direct use as aggregate in high-standard commercial concrete.

◦ Vibration and Energy Consumption: Vibration is significant during operation, resulting in relatively high energy consumption per unit product.

◦ Jaw Plate Wear: When processing highly abrasive river pebbles, the jaw plates wear out quickly and require regular replacement.

2. Cone Crusher: The Shaping Expert for Medium and Fine Crushing

• Working Principle: Through the gyratory motion between the moving and fixed cones, the material undergoes interlayer crushing (particles squeeze and grind against each other).

• Applicable River Pebble Stage: Typically used as secondary (medium and fine) or tertiary crushing. The semi-finished product from the jaw crusher is further crushed to high-quality aggregate ≤40mm.

• Advantages:

◦ Excellent Particle Shape: The interlayer crushing principle results in cubic aggregate with extremely low content of needle-like and flaky particles, making it an ideal raw material for high-performance concrete and resulting in high added value.

• High production efficiency and low energy consumption: Strong continuous operation capability, low unit energy consumption, and significant long-term operating cost advantages.

• Long wear-resistant component life: Modern cone crushers utilize advanced wear-resistant materials and cavity design. While wear does occur when crushing river pebbles, the lifespan is longer than that of jaw plates under the same working conditions.

• Disadvantages:

• High procurement cost: Complex equipment structure, high technical content, and large initial investment.

• Feed requirements: Requires full feed, and preferably primary crushing by a jaw crusher; cannot directly process oversized raw materials.

• High maintenance technical requirements: Repair and adjustment are more complex than with jaw crushers.

II. Marketing Perspective: How to provide customers with the ultimate solution?

As marketing experts, we cannot just sell equipment; we must sell solutions and return on investment. For clients' river pebble crushing projects, our recommended strategy is as follows:

Option A: High-Yield, High-Quality (Large-Scale Sand and Gravel Aggregate Projects)

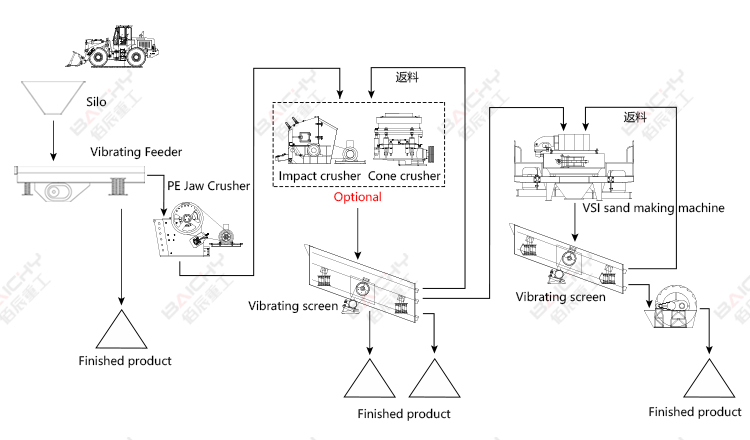

Recommended Configuration: Jaw Crusher + Cone Crusher

This is the most classic and efficient combination. The jaw crusher handles coarse crushing, leveraging its universal crushing capability; the cone crusher handles medium and fine crushing, utilizing its shaping and energy-saving advantages. This combination can stably produce large quantities of high-quality aggregate, meeting the needs of key national projects. Although the initial investment is high, the return on investment is also the highest. This is our flagship solution for medium to large-scale clients.

Option B: Economical and Practical (Small to Medium-Sized or Temporary Projects)

Recommended Configuration: Single-Stage Jaw Crusher (or Heavy-Duty Impact Crusher)

For clients with limited budgets and less stringent requirements for product particle shape, a large-scale jaw crusher can also serve as the core equipment. Additionally, if the river pebbles are not extremely abrasive, modern heavy-duty impact crushers, due to their excellent particle shape and lower cost, are also a worthwhile option. We need to honestly explain to clients the trade-offs between wear parts consumption and product quality in this solution. Returning to the initial question: Which crusher is more suitable for crushing river pebbles?

The answer is: For projects pursuing scale, quality, and long-term benefits, a combined jaw crusher and cone crusher production line is the obvious choice. It represents the industry standard of mature technology, stable operation, and maximized profitability.

As a forward-thinking equipment supplier, we should guide our clients beyond simple equipment price comparisons, focusing instead on the production cost per ton of aggregate and the market price of the final product. The improved particle shape brought by a high-efficiency cone crusher can potentially increase your aggregate's selling price by 10-20 yuan per ton, which far outweighs the tens of thousands of yuan saved in equipment price differences.

Choosing us means not only getting a robust machine, but also a strategic partner with a deep understanding of river pebble crushing technology, dedicated to optimizing your overall return on investment. We welcome you to bring your material samples and capacity requirements at any time to jointly plan the most economical production line solution with us.