The PF1210 impact crusher is a workhorse for crushing medium-hard materials. The key to maintaining its efficient and stable operation lies in meticulous management of its wear parts. Understanding which parts are most susceptible to wear and their approximate replacement cycles is crucial for developing a preventive maintenance plan and controlling operating costs. This article provides a detailed analysis of the PF1210's main wear parts and their replacement cycles.

1. What are the PF1210's main wear parts?

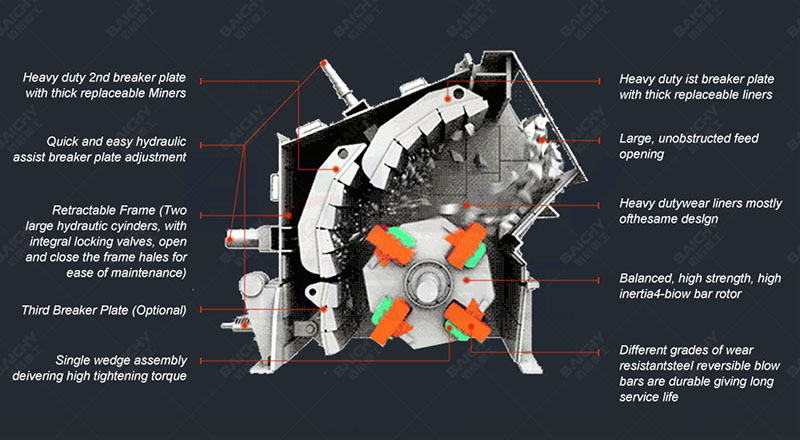

The PF1210's wear parts are primarily concentrated in areas directly involved in impacting and grinding the material. These include the following core components:

1. Blow Bar: This is the most critical component and experiences the most wear. Mounted directly on the high-speed rotating rotor, it is responsible for impacting and crushing the material. Its material and manufacturing process directly impact crushing efficiency and lifespan.

2. Impact Plate (Impact Liner): Located above the rotating striker, it withstands secondary impact from material thrown by the striker, further crushing and shaping the material. It is typically pided into a front impact plate and a rear impact plate.

3. Side guards: Installed inside the frame on both sides, they protect the crusher housing from wear and impact from the material.

4. Impact liner: Installed below the rotor's throwing area, they withstand the impact and friction of small particles.

5. Clamping block: Secures the blow bars to prevent them from loosening during high-speed operation. Wear on the clamping block can affect the hammer's securement.

2. What is the replacement cycle for each wearing part?

The replacement cycle for wearing parts is not a fixed value and is significantly affected by a variety of factors, including:

• Material properties: Material hardness, particle size, moisture content, and silicon content.

• Operating parameters: Crusher feed rate and speed.

• Component quality: The material of the wearing part itself (e.g., high-chromium cast iron, wear-resistant alloy steel, etc.).

The following is the average reference replacement cycle for each wearing part under normal operating conditions when processing medium-hard materials (such as limestone):

| Wear Part Name | Average Reference Replacement Cycle | Influencing Factors and Explanation |

| Blow Bar | Approximately 120-400 hours | The component that wears the fastest. The cycle fluctuates the most, directly related to the material hardness and rotational speed. Regular rotation is required to balance wear. |

| Impact Plate | Approximately 400-800 hours | Wears second only to the blow bar. When front-end wear affects crushing efficiency or shape, it can be swapped or replaced. |

| Side Guard / Impact Liner | Approximately 800-1500 hours | Wears relatively slowly. However, when severely worn, it loses its protective function and requires prompt replacement. |

| Press Block | Usually replaced with the blow bar | It is recommended to replace the press block with each new blow bar to ensure stable and secure fixation. |

Important Note: The above cycle times are for reference only. The most scientific approach is to establish a regular inspection system and determine whether replacement is necessary by measuring the remaining thickness of consumable parts or observing changes in the particle size of the finished product after crushing.

III. How to Effectively Extend the Service Life of Consumable Parts?

1. Scientific Feeding: Strictly control the feed particle size and feed evenly to avoid overloading or the intrusion of metallic foreign objects.

2. Regular Inspection and Adjustment: Regularly inspect consumable parts for wear and promptly adjust the gap between the impact plate and hammer to the optimal state.

3. Select High-Quality Accessories: Invest in branded consumable parts made of high-quality materials and undergoing thorough heat treatment. While the inpidual cost may be higher, the overall lifespan is longer and the overall cost may be lower.

4. Rational Allocation and Use: Components such as the hammer and impact plate can be rotated and replaced to maximize their wear resistance.

Having a clear understanding of the main consumable parts of the PF1210 impact crusher and their replacement cycles is an important part of equipment management. By establishing a preventive maintenance profile and flexibly adjusting your maintenance plan based on actual operating conditions, you can significantly reduce unplanned downtime, effectively control production costs, and maximize your equipment's productivity.

If you need advice on selecting consumable parts for specific materials, please contact our technical experts for professional guidance.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)