In industries such as mining, building materials, and metallurgy, the choice of crushing equipment directly affects production efficiency and cost. Cone crushers and impact crushers are two common secondary crushing equipment, but they have significant differences in working principles, applicable materials, output particle shape, and maintenance costs. This article will comprehensively compare the advantages and disadvantages of the two to help users choose the appropriate crushing equipment according to actual needs.

Working principle comparison

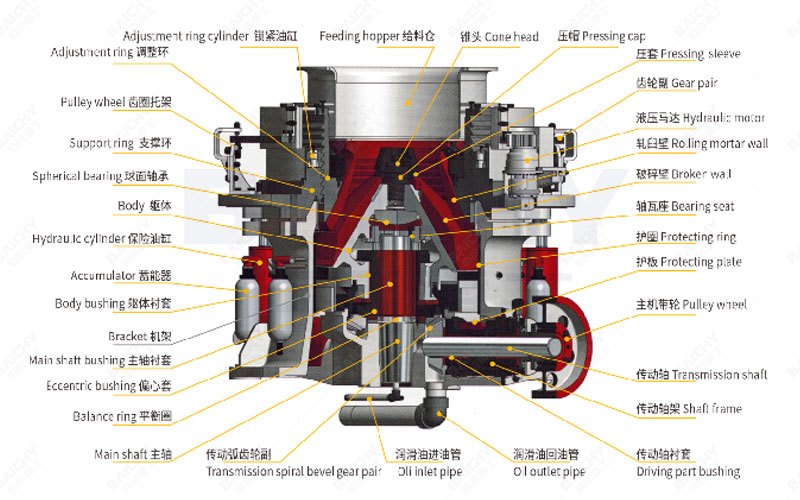

1. Cone crusher

• Crushing method: Adopting the principle of laminated crushing, the material is crushed by the extrusion and grinding between the moving cone and the fixed cone.

Features:

• Suitable for medium and high hardness materials (such as granite and basalt).

• Large crushing ratio, uniform output particle size, suitable for fine crushing.

• Low energy consumption, but the equipment structure is complex and the maintenance cost is high.

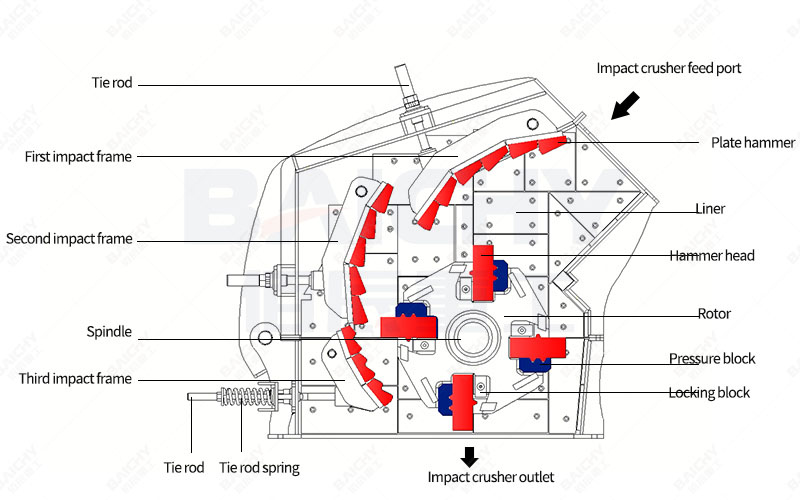

2. Impact Crusher

• Crushing method: Use impact energy to crush, the material hits the impact plate under the impact of the high-speed rotating rotor to achieve crushing.

Features:

• Suitable for medium and low hardness materials (such as limestone, coal gangue).

• The particle shape of the output material is good, but the needle-like content is high, which is suitable for building aggregates.

• Simple structure, easy maintenance, but wear-resistant parts (such as plate hammers) are frequently replaced.

Comparison summary:

| Characteristics | Cone crusher | Impact crusher |

| Crushing method | Extrusion, grinding | Impact crushing |

| Applicable hardness | High hardness (granite, basalt) | Medium and low hardness (limestone, coal gangue) |

| Discharge particle shape | Uniform, mostly cubic | More needle-shaped |

| Energy consumption | Low | High |

| Maintenance cost | High (complex hydraulic system) | Low (easy to replace plate hammer) |

Applicable material comparison

1. Applicable scenarios of cone crusher

• High hardness rock (compressive strength ≥ 250MPa): granite, basalt, diabase, etc.

• Fine crushing requirements: The discharge particle size is required to be uniform (such as 5-30mm), used for high-quality concrete aggregate.

• Long-term stable production: suitable for large stone factories and mines, with low operating costs.

2. Applicable scenarios of impact crusher

• Medium and low hardness materials(compressive strength ≤350MPa): limestone, dolomite, coal gangue, etc.

• Construction aggregate production: The particle shape requirement is not high, but a high output is required.

• Flexible adjustment of discharging: By adjusting the gap between the impact plates, the finished product particle size can be quickly changed.

Selection suggestions:

• Hard rock crushing → Prefer cone crusher(strong wear resistance and long life).

• Soft rock or recycled aggregate → Prefer impact crusher(low cost and simple maintenance).

Comparison of production capacity and cost

| Parameters | Cone crusher | Impact crusher |

| Processing capacity (t/h) | 50-1000 | 50-800 |

| Power consumption (kW·h/t) | Lower | Higher |

| Life of wear-resistant parts | Longer (high manganese steel lining) | Shorter (plate hammer is easy to wear) |

| Initial investment | Higher | Lower |

| Maintenance difficulty | Complex (professional hydraulic maintenance required) | Simple (replace the plate hammer) |

Economic analysis:

• Long-term operation: Cone crusher is more energy-saving, but the maintenance cost is high.

• Short-term or small and medium-sized projects: The impact crusher has a low investment and is suitable for users with limited budgets.

Frequently Asked Questions (FAQ)

Q1: Which one is more suitable for crushing granite, cone crusher or impact crusher?

Cone crusher is more suitable because granite has high hardness, the plate hammer of the impact crusher wears too quickly, and the cost is high.

Q2: Why is the discharge of the impact crusher mostly in the shape of needles and flakes?

The impact crusher relies on impact crushing, and the material is prone to produce edges and corners under high-speed impact, while the laminated crushing of the cone crusher is more likely to form cubic particles.

Q3: Should a small stone plant choose a cone crusher or an impact crusher?

If the budget is limited and the material is soft (such as limestone), the impact crusher is more suitable; if it is processing hard rock and pursuing long-term stable production, the cone crusher is better.

Conclusion and selection suggestions

| Demand | Recommended equipment |

| High-hardness rock (granite, basalt) | Cone crusher |

| Medium and low-hardness materials (limestone, coal gangue) | Impact crusher |

| Fine crushing (5-30mm uniform particle size) | Cone crusher |

| Building aggregate (not high on particle shape) | Impact crusher |

| Long-term stable production, low energy consumption | Cone crusher |

| Short-term project, low-cost investment | Impact crusher |

Final suggestion: Comprehensive selection based on material hardness, discharge requirements, and budget. If you are still unsure, you can consult the equipment manufacturer to conduct a trial test to ensure the best match.