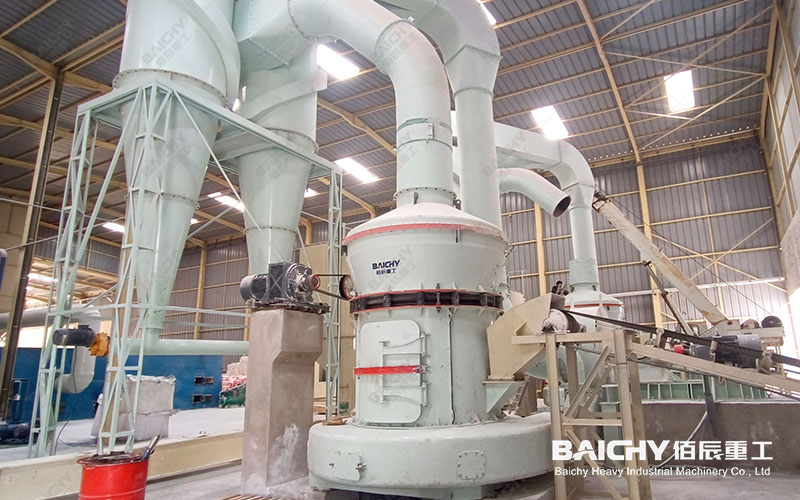

1. What is Raymond Mill?

Raymond roller mill is a high-yield and high-efficiency ore grinding equipment suitable for processing non-metallic minerals with Mohs hardness ≤ 7, such as limestone, calcite, barite, gypsum, talc, etc. The equipment adopts advanced grinding technology and can adjust the fineness of the finished product (80-400 mesh) to meet the needs of different industries, such as building materials, chemical industry, metallurgy, environmental protection and other fields.

Core advantages

✔ High yield and high efficiency: 50 tons of processing capacity per hour, greatly improving production efficiency

✔ Energy saving and environmental protection: optimize air duct design, reduce energy consumption, and reduce dust pollution

✔ Stable and durable: high manganese steel grinding roller and grinding ring, strong wear resistance and long service life

✔ Intelligent control: high degree of automation, easy operation and low maintenance cost

2. Technical parameters of 50 tons/hour Raymond mill

| Parameters | Specifications |

| Model | 5R4128 / 6R4525 |

| Maximum feed particle size | ≤30mm |

| Finished product fineness | 80-400 mesh (adjustable) |

| Production capacity | 40-50 tons/hour |

| Main engine power | 132-160kW |

| Machine weight | 25-35 tons |

| Applicable materials | limestone, calcite, barite, gypsum, talc, etc. |

3. Application industry of Raymond mill

• Building materials industry: used in the production of cement, concrete admixtures, building gypsum powder, etc.

• Chemical industry: grinding of fine chemical raw materials (such as calcium carbonate, talcum powder)

• Metallurgical industry: ore dressing, tailings treatment

• Environmental protection industry: recycling of industrial solid waste (such as desulfurized gypsum)

4. FAQ

Q1: What is the price of a 50-ton Raymond mill?

The price fluctuates due to different configurations and market conditions. Welcome to consult customer service for the latest quotation!

Q2: How long does it take to install and debug the equipment?

We provide full technical guidance, and generally the installation and debugging can be completed in 3-7 days.

Q3: How long is the service life of the equipment?

Under normal maintenance, the core components (grinding rollers and grinding rings) can be used for 3-5 years, and the service life of the whole machine can reach more than 10 years.