1. What is a ballast crusher?

Ballast crusher (also known as railway ballast crusher) is a stone crushing equipment specially used to crush hard rocks such as granite and basalt to produce stone crushing equipment that meets the standards of railway ballast (ballast). The crushed stones must meet the requirements of high strength, wear resistance, compressive stability, etc. to ensure the stability and drainage performance of the railway roadbed.

1.1 The role of railway ballast

• Disperse pressure: evenly distribute train loads to prevent track settlement.

• Drainage and antifreeze: The gap between crushed stones promotes drainage and reduces the harm of frost heave.

• Shock reduction and noise reduction: absorb the vibration of train operation and reduce noise pollution.

2. Main types and features of ballast crushers

Based on the crushing principle and finished product requirements, common ballast crushers include the following:

2.1 Jaw crusher (coarse crushing)

• Applicable materials: large granite, basalt (feed size ≤1200mm).

• Features: large crushing ratio, simple structure, easy maintenance, suitable for primary crushing.

2.2 Cone crusher (medium and fine crushing)

• Applicable materials: medium hardness rock, finished product size 5-60mm.

• Features: hydraulic adjustment of discharge port, high crushing efficiency, good stone particle shape.

2.3 Impact crusher (shaping sand making)

• Applicable materials: railway ballast with high requirements for stone particle shape.

• Features: "stone hitting stone" crushing principle, high cubic rate of finished products, and reduced needle-like particles.

2.4 Mobile crushing station (flexible operation)

• Applicable scenarios: on-site crushing in mines and operations along railway construction lines.

• Features: integrated unit, no need for fixed foundation, can be quickly transferred.

3. How to choose a ballast crusher? Key parameter analysis

When purchasing a ballast crusher, you need to consider factors such as production capacity, stone hardness, and finished product specifications:

| Parameter | Reference range | Description |

| Feed particle size | ≤800mm (jaw crusher) | Large rocks need to be pre-crushed |

| Discharge particle size | 16-63mm (railway standard) | Meet TB/T 2140-2008 ballast specification |

| Capacity | 50-500 tons/hour | Match according to railway engineering needs |

| Motor power | 55-400kW | High-power equipment is suitable for hard rock crushing |

Purchase suggestions:

Granite/basalt: Prefer cone crusher + impact crusher combination to ensure that the particle shape meets the standard.

Small and medium-sized projects: Mobile crushing stations are more flexible and reduce transportation costs.

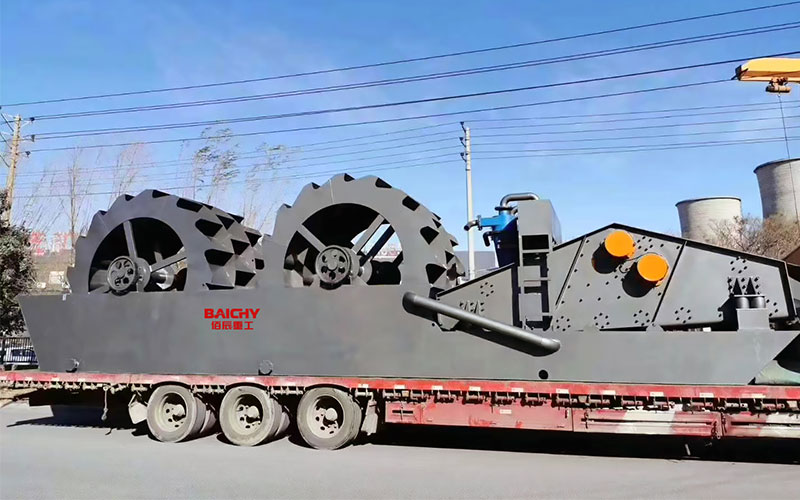

4. Core advantages of Baichy Heavy Industry ballast crusher

As a manufacturer focusing on mining crushing equipment for 20 years, Baichy Heavy Industry's ballast crusher has the following advantages:

✔ High wear-resistant material: Mn18Cr2 alloy lining is used, and the service life is extended by 30%.

✔ Intelligent control system: Real-time monitoring of crushing chamber pressure and automatic adjustment of discharge port.

✔ Customized solution: Provide fixed/mobile production line design according to customer needs.

✔ Global case: Equipment is exported to 30+ countries, serving major projects such as Beijing-Zhangjiakou High-speed Railway and China-Laos Railway.

5. Railway ballast production process

A typical ballast crushing production line includes the following links:

Explosive mining → 2. Jaw coarse crushing → 3. Cone medium crushing → 4. Impact shaping → 5. Screening and grading → 6. Finished product storage

6. Frequently Asked Questions (FAQ)

Q1: What is the difference between a ballast crusher and an ordinary stone crusher?

A: Ballast crushers pay more attention to particle shape control (cubic rate ≥ 90%), while ordinary stone crushers may only pursue crushing efficiency.

Q2: Granite and limestone, which one is more suitable for railway ballast?

A: Granite has higher hardness (Mohs hardness 6-7) and strong compressive strength, and is the preferred material for railway ballast.

Q3: How much does it cost to invest in a ballast crushing production line?

A: Depending on the capacity configuration, the price is usually between 800,000 and 5 million, and installment payment plans can be provided.

Ballast crushers are the core equipment of railway construction. It is crucial to choose equipment with high reliability and high yield. Baichy Heavy Industry provides free technical consultation, on-site inspection, and customized solution services. Welcome to leave a message online to get the latest quotation!

Further reading: