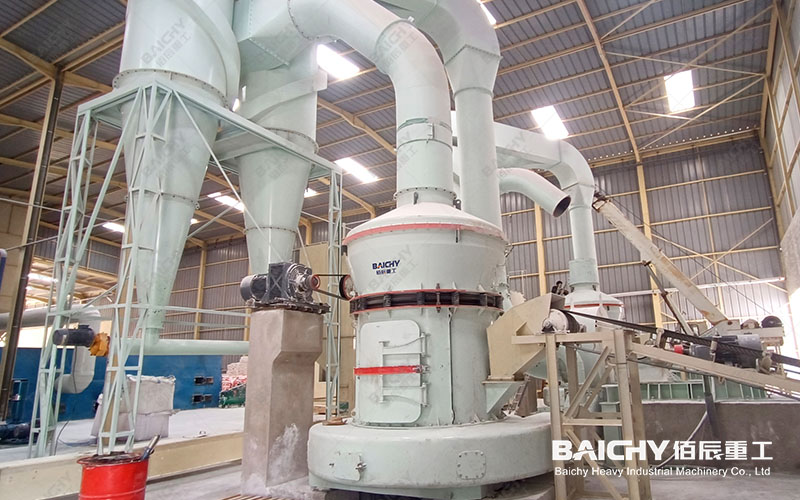

5R Large Raymond Mill (Inner Diameter 1250-1300mm) Price

In non-metallic mineral deep processing, building materials, metallurgy, and other industries, when projects enter the large-scale, industrialized production stage, equipment selection becomes crucial in determining the return on investment. Large Raymond mill grinders with an inner diameter of 1250-1300 mm, typically the 5R series, are core equipment designed to meet medium-to-high production demands of several to more than ten tons per hour. As a mining equipment manufacturer with 20 years of R&D and manufacturing experience, we understand that behind customer inquiries about "5R Raymond mill prices" lies a comprehensive consideration of system stability, output efficiency, and long-term operating costs. This article will provide a comprehensive analysis of this equipment to help you make informed decisions.

Grinding Mill PDF, Download ↓↓↓

Beyond "Price": Unveiling the True Value of the 5R Raymond Mill

Equipment Overview and Positioning

The 5R Raymond mill grinder (such as the 5R4121/4128 model) belongs to the large-scale models of pendulum grinding mills. Its core features include a larger grinding chamber (inner diameter 1250-1300mm) and 5 large grinding roller devices, which means a larger grinding area and stronger processing capacity. It is mainly positioned for large-scale grinding of medium-hardness materials (Mohs hardness below 7), such as calcite, limestone, barite, feldspar, gypsum, dolomite, etc., with adjustable finished product fineness usually between 80-400 mesh.

In-depth Analysis of Price Components

Customers often directly inquire about the price of Raymond mill grinders, but the price of a 5R mill is a "system engineering" project. The total cost includes:

1. Main machine cost: Depends on the materials used (such as the thickness of the steel plate of the frame, the material and process of the gears).

2. Core grinding component configuration: Whether the grinding rollers and grinding rings use ordinary 65 manganese steel or high wear-resistant alloy steel, the price difference can be more than 30%, but the service life may differ by several times, directly affecting long-term downtime and maintenance costs.

3. Supporting systems: The price difference is huge between a single machine and a complete production line including jaw crusher, feeder, elevator, piping, pulse dust collector, and intelligent electrical control system. 4. Technological Added Value: Does it utilize energy-saving and consumption-reducing designs such as centralized lubrication systems, maintenance-free blades, and variable frequency speed control feeding?

Therefore, "price" is essentially a monetary representation of technical configuration, manufacturing process, and after-sales service commitments.

5R Large Raymond Mill (Inner Diameter 1250-1300mm) Price

Our Core Advantages: 20 Years of Focus, Creating High-Performance and Stable Production Lines

Based on twenty years of technical expertise and market insight in mining crushing and grinding equipment, our 5R series Raymond mill solutions offer outstanding advantages:

• Optimized Design, More Stable Output: Addressing the pain points of traditional Raymond mills with high air duct resistance and low classification efficiency, we have optimized the volute air duct curve and classifier impeller angle, resulting in smoother system ventilation and approximately 15% higher output at the same power, with more uniform finished product fineness.

• Upgraded Materials, Longer Lifespan: Key wear parts (grinding rollers, grinding rings) use our independently developed multi-element alloy steel, and through special heat treatment processes, perform excellently against abrasive materials. The service life is 40% longer than average market standard parts, significantly reducing the cost of consumables per ton of powder.

• Intelligent Control, Easier Operation: Optional PLC electrical control system enables centralized start/stop, fault alarms, and remote monitoring, reducing reliance on skilled operators and ensuring production safety and continuity.

• Turnkey Project, Worry-Free and Effortless: We not only provide single machines but can also design and provide complete grinding production line solutions from crushing, conveying, grinding to collection and packaging, based on your material characteristics and plant layout, and provide installation guidance and commissioning services.

Successful Case Studies: Stable Operation is the Ultimate Proof of Value

• Case Study 1: A large calcium carbonate powder enterprise in Henan Province

◦ Requirements: To process limestone into 250-mesh heavy calcium carbonate powder, requiring a stable output of more than 10 tons per hour and high equipment continuous operation rate.

◦ Solution: We configured a complete system for them, including "jaw crusher + 5R4128 Raymond mill + high-efficiency pulse dust collector," with core grinding parts made of special alloy steel. • Results: The production line has been running stably for over 3 years, with an annual operating time exceeding 300 days, achieving the design target of 12-14 tons per hour. The customer is very satisfied with the durability of the equipment and our timely spare parts supply service.

Related Equipment Recommendations: Building an Efficient and Complete Production System

An efficient 5R Raymond mill requires perfect coordination with upstream equipment:

• PE series jaw crusher: Used for coarse crushing of raw ore, controlling the particle size of the material entering the mill (usually ≤30mm), it is the "outpost" that ensures the efficient operation of the mill.

• GX series bucket elevator & electromagnetic vibrating feeder: Realizes vertical material conveying and uniform, quantitative feeding, acting as the "regulator" for the stability of the production process.

• PPC series air box pulse bag dust collector: Collects finished powder while achieving environmentally friendly emissions, with a dust removal efficiency of >99.9%, acting as the "guardian" of green production.

Frequently Asked Questions (FAQ)

Q1: What is the approximate price range for a 5R Raymond mill main unit?

A1: Depending on the configuration and materials, the market price of a single 5R Raymond mill main unit (excluding supporting equipment) is usually between RMB 300,000 and 600,000. We recommend that you provide specific material, fineness, and output requirements so that we can provide you with accurate configuration and transparent pricing.

Q2: How long does it take from placing an order to equipment installation and commissioning?

A2: For a standard configuration 5R main unit, the production cycle is approximately 30-45 days. If a complete production line is required, the cycle will be extended accordingly. We have a mature supply chain and large workshops, which can effectively guarantee delivery time, and we can send engineers to conduct on-site surveys and guide foundation construction in advance.

Q3: How does your equipment compare to similar products on the market in terms of energy efficiency?

A3: By using more efficient centrifugal fans, optimizing the transmission system to reduce unnecessary power consumption, and incorporating variable frequency technology, our 5R grinding system can reduce overall power consumption by 8%-15% at the same output. We are happy to provide you with detailed power configuration instructions in the quotation.

About of Baichy Heavy Industry

Baichy Heavy Industry is a high-tech mining equipment company integrating R&D, manufacturing, sales, and after-sales service. Focusing on crushing, grinding, and mineral processing equipment, we provide professional solutions to our customers. We are ISO9001:2015 、certified, and our products include mobile crushing palnts, crawler crushing plant, construction waste crushing plants, jaw crushers, sand making machines, cone crushers, fine crushers, grinding mills, ball mills, etc., all with reliable performance to meet diverse project needs.

Our advantages:

• Professional pre-sales support: Free project design and comprehensive solutions to help you accurately select the right equipment;

• Comprehensive on-site service: Providing installation guidance and worker training to ensure smooth equipment commissioning;

• Reliable after-sales guarantee: A complete after-sales system, timely response to technical inquiries and equipment maintenance, ensuring long-term stable operation.

To protect your rights, please contact us through the following official channels for professional service:

Official Website Customer Service

WhatsApp: 0086-15093222637

Email: [email protected]

We are committed to providing high-quality equipment and full-cycle services to deliver comprehensive intelligent solutions for the global mining industry!