Granite, a hard and wear-resistant natural rock, is an excellent raw material for producing high-quality manufactured sand. Granite sand is widely used in construction, concrete, highway construction, and many other fields. So, what key equipment is needed to transform large blocks of granite ore into high-quality sand that meets specifications? This article will provide a detailed analysis of the arsenal of granite sand production.

I. Core Crushing Equipment: From Large Blocks to Small Particles

The core of the entire sand-making process is crushing and shaping. A standard granite sand production line typically employs a multi-stage crushing process to ensure efficiency and product quality.

1. Primary Crushing (Coarse Crushing) Equipment: Jaw Crusher

◦ Role: The vanguard of the production line. Its task is to process large blocks of granite (hundreds or even thousands of millimeters in diameter) transported from the mine, crushing them into smaller blocks of less than 250 millimeters.

◦ Features: Characterized by its robust structure, large processing capacity, and strong crushing force, it is the preferred coarse crushing equipment for processing high-hardness granite.

2. Medium and Fine Crushing Equipment: Cone Crusher or Impact Crusher

◦ Role: The backbone of the production line. Responsible for further processing the coarsely crushed stone into smaller particles (usually less than 40-50mm), preparing for the sand making stage.

◦ Selection Recommendations:

▪ Cone Crusher: More suitable for crushing high-hardness, highly abrasive granite. It uses the principle of layered crushing, resulting in long wear parts life and good finished particle shape, but the price is relatively high.

▪ Impact Crusher: Uses the principle of impact crushing, producing better finished particle shape (cubic), but the impact plates wear relatively quickly, making it more suitable for medium to low hardness materials. For granite, if extremely high particle shape requirements are needed and the raw material hardness is not particularly high, it can also be selected.

II. Core Sand Making and Shaping Equipment: Key to Creating High-Quality Sand

3. Core Sand Making (Shaping) Equipment: Vertical Shaft Impact Crusher

◦ Role: The soul of the production line. This is equipment specifically designed for producing manufactured sand. It utilizes the principle of stone-on-stone or stone-on-iron crushing, subjecting finely crushed stones to high-speed impact, collision, and friction, making them finer and correcting their particle shape to produce high-quality granite sand with good roundness and reasonable gradation.

◦ Features: Combines crushing and shaping functions, high sand production rate, adjustable finished sand particle shape, and is a standard feature of modern sand and gravel aggregate production lines.

III. Auxiliary Screening and Cleaning Equipment: The Beauticians of Sand Quality

4. Screening Equipment: Vibrating Screen

◦ Role: The quality inspector and dispatcher of the production line. It uses screens of different sizes to classify the crushed material according to size. Large, unqualified particles are returned to the next stage for re-crushing, while qualified particles are conveyed to the next stage. This ensures that the final finished sand has uniform particle size and reasonable gradation.

5. Cleaning and Impurity Removal Equipment: Sand Washing Machine

◦ Role: The cleaner of the production line. The produced granite sand contains stone powder and impurities on its surface. Sand washing machines effectively remove excess stone powder, mud, and other impurities from sand through water washing and agitation, significantly improving the cleanliness of the sand and enabling it to meet high-standard construction sand requirements.

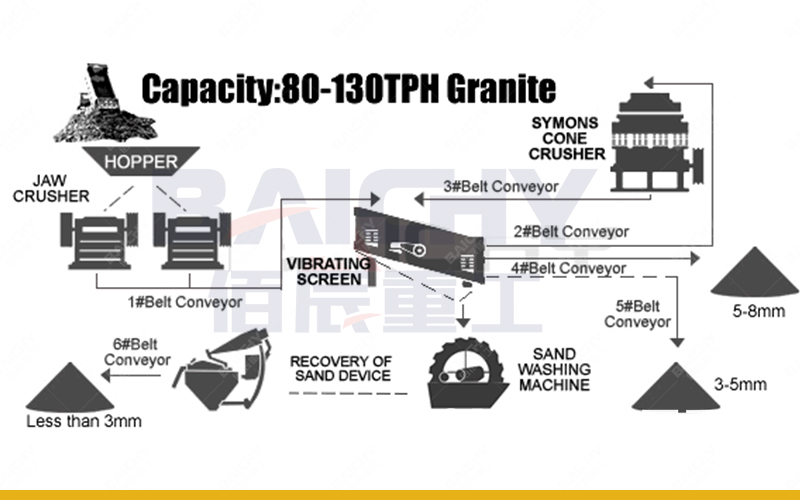

Granite Sand Making Process Overview: Large granite → (Jaw Crusher: Coarse Crushing) → Medium-sized stones → (Cone Crusher: Medium and Fine Crushing) → Small stones → (Vibrating Screen: Screening) → Qualified stones → (Sand Making Machine: Sand Shaping) → Coarse sand → (Vibrating Screen: Inspection Screening) → Finished sand → (Sand Washing Machine: Cleaning) → Clean, high-quality granite sand.

Choosing the right combination of granite sand making equipment is the cornerstone of building an efficient, energy-saving, and environmentally friendly sand and gravel production line. A well-configured production line (jaw crusher + cone crusher + sand making machine + screening and washing equipment) not only ensures output and finished product quality but also effectively controls operating costs and environmental impact. Before investing, it is recommended to consult professional equipment suppliers for customized solutions based on your raw material characteristics, production capacity requirements, and finished product standards.