This is a detailed and practical configuration plan for a 200 tph sand and gravel aggregate crushing line.

This plan adheres to the core principle of "more crushing, less grinding, and staged crushing," designed with energy conservation, high efficiency, excellent finished product particle shape, and low operating costs as the goals.

I. Core Design Concepts

1. Product Positioning: Production of conventional concrete aggregate (0-5mm machine-made sand, 5-10mm, 10-20mm, and 20-31.5mm gravel).

2. Raw Material Analysis: The raw materials are assumed to be common limestone, granite, and other medium-hard materials (compressive strength <150 MPa). For harder materials or those with high mud content, the plan will require minor adjustments.

3. Process Design: The three-stage crushing process of "coarse crushing + medium and fine crushing + sand shaping" is adopted, combined with an efficient screening system to form a closed-loop system to ensure product particle size.

II. Recommended Conventional Configuration (Option A: Cone Crusher + Impact Crusher)

This is currently the most mainstream configuration with the best overall performance. It is suitable for hard rock, produces excellent product shape, and maintains manageable operating costs.

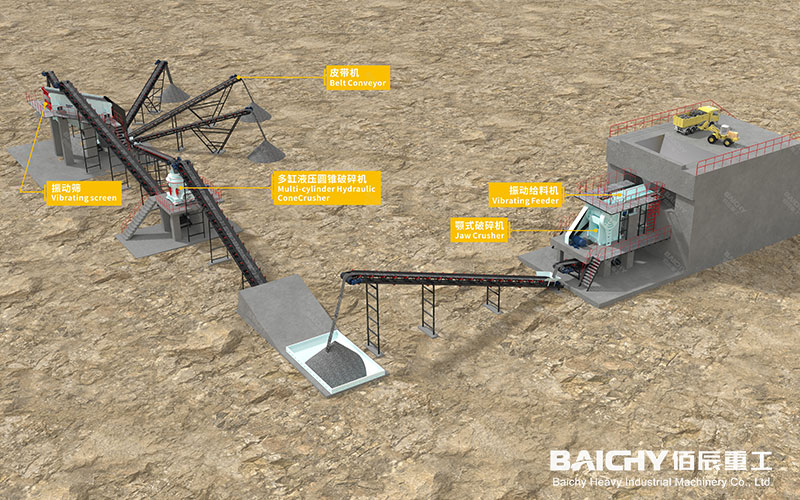

Core Process: Feeding → Coarse Crushing (Jaw Crusher) → Secondary and Fine Crushing (Cone Crusher) → Screening (Pre-screening) → Sand Shaping (Impact Crusher) → Screening (Finished Product Screening) → Sand Washing (Optional) → Finished Aggregate.

Specific Equipment Configuration List:

| Process | Equipment Name | Recommended Model (Example) | Power (kW) | Quantity (units) | Core Function |

| 1. Feeding | Vibrating Feeder | GZD-960×3800 or ZSW-490×110 | 11 | 1 | Uniform feeding, preliminary screening to remove dirt |

| 2. Coarse Crushing | Jaw Crusher | PE-600×900 or PE-750×1060 | 75-110 | 1 | Crushing large lumps of raw stone to ≤200mm |

| 3. Secondary and Fine Crushing | Single-Cylinder Hydraulic Cone Crusher | HST-160/Single-Cylinder-160 | 160-200 | 1 | Crushing coarse material to ≤60mm, the mainstay of aggregate production |

| 4. Transfer | Belt Conveyor | B650-B800 | Depending on length | 7 | Material conveying, connecting various links |

| 5. Screening (I) | Circular Vibrating Screen | 3YK-1860 or 2YK-1860 | 22-30 | 1 | Classify the output from the cone crusher, returning large particles to the cone crusher (closed circuit) |

| 6. Sand Shaping | Vertical Shaft Impact Crusher | VSI-1140 or 5X-1145 | 180-260 | 1 | Shape the intermediate particle size (e.g., 20-40 mm) after screening |

| 7. Screening (II) | Circular Vibrating Screen | 3YK-2160 or 4YK-1860 | 30-37 | 1 | Grades the sand making machine output to produce a variety of finished products, with the oversized fraction returned to the sand making machine. |

| 8. Sand Washing (Optional) | Wheel Sand Washer | XS-3016 | 7.5-11 | 1-2 | Cleans machined sand to remove stone dust and impurities, improving quality. |

| 9. Auxiliary | Dust Removal System | Pulse Bag Dust Collector | - | 1 | Covering all dust-generating points, meeting environmental requirements. |

| 10. Electronic Control | Centralized Electronic Control System | PLC Centralized Control | - | 1 | Integrated control for automated production |

Process Flow Diagram:

III. Other Configuration Options (Alternative Options)

Option B: Impact Crusher (Suitable for Medium-Hard, Low-Abrasive Materials)

• Features: Lower investment cost, excellent finished product shape, but faster hammer wear than cone crusher. Suitable for limestone, etc. • Process Change: Replace the cone crusher in the secondary and tertiary crushing stage with an impact crusher (such as the PF-1320/PF-1520).

• Advantages: Provides good product shape and gradation.

• Disadvantages: Short wear-resistant parts life; not suitable for hard rock.

Option C: Pure Jaw Crusher + Impact Crusher (Simplified, Lowest Investment)

• Features: Combining a jaw crusher and an impact crusher in two stages, this system offers a simple structure and low investment, but the product particle size control, shape, and gradation are relatively poor.

• Applicable: Low-standard or temporary projects with low requirements for the finished product.

IV. Summary of Solution Features (Option A Recommended)

1. Mature and Reliable Technology: The three-stage crushing process is the industry standard, offering stable operation and easy maintenance.

2. High Product Quality: The cone crusher is responsible for efficient crushing, while the impact crusher is responsible for shaping. The resulting stone particles are cubic in shape, and the manufactured sand is well-graded and angular, significantly enhancing the value of the aggregate product.

3. Economical Operating Costs: The cone crusher's wear parts have a long lifespan, offering significant advantages for hard rock processing and low long-term operating costs.

4. Environmental Compliance: The entire production line utilizes a sealed dust removal design, effectively controlling dust and meeting national environmental protection requirements.

5. High Level of Automation: PLC centralized control enables one-touch start and stop, fault alarms, and remote monitoring, reducing manual operations.

V. Investment Estimation and Key Points

• Equipment Investment: The purchase cost of core equipment alone (excluding construction, installation, and power capacity expansion) ranges from RMB 1.5 million to RMB 3 million, depending on the brand selected (imported, first-tier domestically produced, or standard domestically produced).

• Floor Space: The entire production line is compactly laid out, approximately 50-80 meters long and 30-40 meters wide. Space must be reserved for equipment maintenance and material storage, resulting in a total area of approximately 2,000-4,000 square meters. • Total Power: The total installed power of the entire production line is approximately 550-750kW, with actual operating power consumption approximately 70%-80%. Transformer capacity should be considered.

• Staffing: An automated production line requires only 2-3 people per shift to operate and oversee it.

Key Tips:

• Raw Material Testing: Before finalizing your plan, be sure to conduct a material analysis of your raw materials (for hardness, silicon content, mud content, initial particle size, etc.). Ideally, provide samples to the equipment manufacturer for crushing tests; this provides the most scientific basis for selection.

• Manufacturer Selection: Choose a reputable equipment supplier who can provide not only inpidual machines but also proven complete solutions and after-sales support.

• Environmental Priority: Be sure to consider a comprehensive environmental protection plan (dust removal, noise control, and wastewater recycling) from the initial planning stages to avoid future modifications.

Baichy Heavy Industry – Your Trusted Partner for Seamless Equipment Operation

To ensure optimal performance of your equipment, Baichy Heavy Industry offers:

- Professional on-site installation guidance

- Comprehensive operator training

- 24/7 technical support & maintenance services

Our complete after-sales service system guarantees long-term, stable operation of your machinery with minimal downtime.

Protect Your Rights – Only Use Official Channels

To avoid scams and ensure authentic support, contact us exclusively through:

• Official Website: www.baichychina.com

• WhatsApp: +8615093222637

• Email: [email protected]

Your satisfaction is our priority – expect prompt, professional service every time.

(Note: Beware of unauthorized third parties claiming to represent Baichy. Always verify through official contacts.)